RunwayOverrunDuringRejectedTakeoff

GlobalExecAviation

BombardierLearjet60,N999LJ

Columbia,SouthCarolina

September19,2008

Accident Report

NTSB/AAR-10/02

PB2010-910402

National

Transportation

Safety Board

NTSB/AAR-10/02

PB2010-910402

Notation 8061B

Adopted April 6, 2010

Aircraft Accident Report

Runway Overrun During Rejected Takeoff

Global Exec Aviation

Bombardier Learjet 60, N999LJ

Columbia, South Carolina

September 19, 2008

National

Transportation

Safety Board

490 L’Enfant Plaza, S.W.

Washington, D.C. 20594

National Transportation Safety Board. 2010. Runway Overrun During Rejected Takeoff, Global Exec

Aviation, Bombardier Learjet 60, N999LJ, Columbia, South Carolina, September 19, 2008. Aircraft

Accident Report NTSB/AAR-10/02. Washington, DC.

Abstract: This report describes the September 19, 2008, accident involving a Bombardier Learjet

Model 60 (Learjet 60), N999LJ, which overran runway 11 during a rejected takeoff at Columbia

Metropolitan Airport, Columbia, South Carolina, while operating as a 14 Code of Federal Regulations

Part 135 unscheduled passenger flight. The captain, the first officer, and two passengers were killed; two

other passengers were seriously injured.

The safety issues discussed in this report include the criticality of proper aircraft tire

inflation; maintenance requirements and manual revisions for tire pressure check intervals; tire

pressure monitoring systems; airplane thrust reverser system design deficiencies; inadequate

system safety analyses by the Federal Aviation Administration (FAA) and Learjet; inadequate

level of safety in the certification of changed aeronautical products; flight crew training for tire

failure events; flight crew performance, including the captain’s action to initiate an rejected

takeoff after V

1

, the captain’s experience, and crew resource management techniques; and

considerations for tire certification criteria. Safety recommendations concerning these issues are

addressed to the FAA.

The National Transportation Safety Board (NTSB) is an independent federal agency dedicated to promoting

aviation, railroad, highway, marine, pipeline, and hazardous materials safety. Established in 1967, the agency is

mandated by Congress through the Independent Safety Board Act of 1974 to investigate transportation accidents,

determine the probable causes of the accidents, issue safety recommendations, study transportation safety issues, and

evaluate the safety effectiveness of government agencies involved in transportation. The NTSB makes public its

actions and decisions through accident reports, safety studies, special investigation reports, safety recommendations,

and statistical reviews.

Recent publications are available in their entirety on the Internet at <http://www.ntsb.gov>. Other information about

available publications also may be obtained from the website or by contacting:

National Transportation Safety Board

Records Management Division, CIO-40

490 L’Enfant Plaza, SW

Washington, DC 20594

(800) 877-6799 or (202) 314-6551

NTSB publications may be purchased, by individual copy or by subscription, from the National Technical

Information Service. To purchase this publication, order report number PB2010-910402 from:

National Technical Information Service

5285 Port Royal Road

Springfield, Virginia 22161

(800) 553-6847 or (703) 605-6000

The Independent Safety Board Act, as codified at 49 U.S.C. Section 1154(b), precludes the admission into evidence

or use of NTSB reports related to an incident or accident in a civil action for damages resulting from a matter

mentioned in the report.

NTSB Aircraft Accident Report

Contents

Contents .......................................................................................................................................... i

Figures ........................................................................................................................................... iv

Acronyms and Abbreviations .......................................................................................................v

Executive Summary ................................................................................................................... viii

1. Factual Information ...................................................................................................................1

1.1 History of Flight .........................................................................................................................1

1.2 Injuries to Persons ......................................................................................................................3

1.3 Damage to Airplane ...................................................................................................................3

1.4 Other Damage ............................................................................................................................3

1.5 Personnel Information ................................................................................................................3

1.5.1 Captain .............................................................................................................................4

1.5.2 First Officer .....................................................................................................................5

1.5.3 Flight Crew’s 72-Hour History ........................................................................................6

1.6 Airplane Information .................................................................................................................7

1.6.1 Main Landing Gear Tires .................................................................................................7

1.6.2 Engine Power Control and Thrust Reverser System Control ..........................................9

1.6.2.1 Commanding Forward Thrust ..........................................................................11

1.6.2.2 Commanding Reverse Thrust ..........................................................................11

1.6.2.3 Thrust Reverser System Logic Criteria............................................................12

1.7 Meteorological Information .....................................................................................................12

1.8 Aids to Navigation ...................................................................................................................12

1.9 Communications ......................................................................................................................13

1.10 Airport Information ................................................................................................................13

1.11 Flight Recorders .....................................................................................................................13

1.12 Wreckage and Impact Information ........................................................................................14

1.13 Medical and Pathological Information ...................................................................................14

1.14 Fire .........................................................................................................................................15

1.15 Survival Aspects ....................................................................................................................15

1.15.1 Survivors’ Descriptions of Crew-Provided Safety Information ..................................16

1.15.2 Survivors’ Descriptions of Exiting the Airplane .........................................................16

1.15.3 Postaccident Examination of Airplane Exits ...............................................................17

1.16 Tests and Research .................................................................................................................17

1.16.1 Sound Spectrum Study ................................................................................................17

1.16.1.1 Engine N1 ......................................................................................................17

1.16.1.2 Airplane Ground Speed..................................................................................18

1.16.2 Airplane Performance Study and Map Overlay ...........................................................19

1.16.3 Main Landing Gear Tires .............................................................................................21

1.16.3.1 Basic Design and Function ............................................................................21

i

NTSB Aircraft Accident Report

1.16.3.2 Reconstruction and Examination of Accident Airplane’s Main Landing Gear

Tires and Wheels ............................................................................................21

1.16.3.3 Tire Pressure Data Collected from In-Service Airplanes ..............................23

1.16.4 Thrust Reverser System ...............................................................................................24

1.16.4.1 Ground Tests and Engineering Review .........................................................24

1.16.4.2 Accidents and Incident Involving Thrust Reverser System Anomalies ........25

1.16.4.3 Approved Modifications After 2001 Landing Accident ................................26

1.16.5 Certification of the Learjet 60 as a Changed Aeronautical Product ............................27

1.16.5.1 Thrust Reverser Control Design ....................................................................28

1.16.5.2 Protection of Equipment in Wheel Wells ......................................................29

1.16.6 Comparison of Certification Criteria for Learjet 45 and Learjet 60 ............................29

1.16.6.1 Thrust Reverser System Design .....................................................................30

1.16.6.2 Protection of Equipment in Wheel Wells ......................................................30

1.17 Organizational and Management Information .......................................................................30

1.17.1 Main Landing Gear Tire Maintenance and Checks .....................................................31

1.17.2 Pilot Training and Standard Operating Procedures .....................................................31

1.17.2.1 Rejected Takeoff ............................................................................................32

1.17.2.2 Pretakeoff Passenger Briefing ........................................................................33

1.17.2.3 Airplane Weight and Balance Calculations ...................................................34

1.17.3 Federal Aviation Administration Oversight ................................................................34

1.18 Additional Information ..........................................................................................................35

1.18.1 Takeoff Safety Training Aid ........................................................................................35

1.18.2 Postaccident Safety Action ..........................................................................................36

1.18.2.1 Learjet Tire Servicing Advisory Wire ...........................................................36

1.18.2.2 Federal Aviation Administration Safety Alert for Operators ........................36

1.18.2.3 Learjet Revisions to Flight and Maintenance Manuals ..................................37

1.18.2.3.1 Temporary Flight Manual Change, Revised Procedures ..................... 37

1.18.2.3.2 Temporary Revision to Maintenance Manual ...................................... 37

1.18.2.4 Federal Aviation Administration Legal Interpretation That Learjet 60 Tire

Pressure Checks Are Preventive Maintenance ...............................................38

1.18.3 Previously Issued Safety Recommendations ...............................................................38

1.18.3.1 Learjet 60 Thrust Reverser System Recommendations Resulting From This

Accident Investigation ....................................................................................38

1.18.3.2 Ongoing Assessment of Safety-Critical Systems ..........................................40

1.18.3.3 Crew Resource Management .........................................................................41

1.18.3.4 Onboard Flight Recorder Systems .................................................................42

1.18.4 Current Airworthiness Requirements and Guidance for the Certification of Changed

Aeronautical Products .................................................................................................43

1.18.5 Tire Pressure Monitoring Systems in Aircraft Applications .......................................43

1.18.6 Tire Load Certification Requirements .........................................................................44

1.18.6.1 Learjet 60 Tire Selection ................................................................................45

1.18.6.2 Effect of Tire Camber Angle on Tire Sidewall Loads ...................................45

1.18.7 Takeoff Accident and Incident Data ............................................................................46

1.18.7.1 High-Speed Rejected Takeoffs ......................................................................46

1.18.7.2 Airplane Types Involved in Tire-Related Events ..........................................46

1.18.7.3 Pilot Accounts of Real and Simulated Tire Failure Events ...........................46

ii

NTSB Aircraft Accident Report

2. Analysis .....................................................................................................................................48

2.1 General .....................................................................................................................................48

2.2 Accident Sequence ...................................................................................................................49

2.2.1 Captain’s Initiation of Rejected Takeoff After V

1

.........................................................49

2.2.2 Uncommanded Forward Thrust Emergency ..................................................................51

2.3 Airplane Issues .........................................................................................................................53

2.3.1 Tire Failures ...................................................................................................................53

2.3.1.1 Operator’s Tire Maintenance Practices ............................................................54

2.3.1.2 Maintenance Manual References to Tire Pressure Check Intervals ................54

2.3.1.3 Lack of Tire Pressure Information for Flight Crews .......................................56

2.3.2 Thrust Reverser System Deficiencies ............................................................................56

2.3.3 Safety of Changed Aeronautical Products .....................................................................60

2.4 Flight Crew Performance .........................................................................................................62

2.4.1 Lack of Training for Tire-Related Events .....................................................................62

2.4.2 Captain’s Experience in the Learjet 60 and as Pilot-in-Command ................................63

2.4.3 Crew Resource Management .........................................................................................65

2.4.4 Medication Use and Rest Opportunities ........................................................................66

2.5 Occupant Survivability ............................................................................................................67

2.6 Other Safety Issues ..................................................................................................................68

2.6.1 Tire Certification and Testing Considerations ...............................................................68

2.6.2 Flight Recorders .............................................................................................................69

3. Conclusions ...............................................................................................................................71

3.1 Findings....................................................................................................................................71

3.2 Probable Cause.........................................................................................................................73

4. Recommendations ....................................................................................................................74

4.1 New Recommendations ...........................................................................................................74

4.2 Previously Issued Recommendations Resulting From This Accident Investigation and

Classified in This Report ........................................................................................................76

5. Appendixes ...............................................................................................................................78

Appendix A: Investigation and Hearing ........................................................................................78

Appendix B: Cockpit Voice Recorder Transcript ..........................................................................79

iii

NTSB Aircraft Accident Report

Figures

Figure 1. Learjet factory technician checking inboard tire pressure (left image) and outboard tire

pressure (right image). .....................................................................................................................9

Figure 2. Captain's side view of Learjet 60 thrust levers (at idle) and thrust reverser (piggyback)

levers. To illustrate lever movement, one thrust reverser lever is in the stowed position, and the

other is lifted to command reverse thrust (arrow shows direction lever moves when lifted from

the stowed position). ........................................................................................................................9

Figure 3. Learjet 60 with thrust reversers deployed. The dotted yellow lines show the stowed

position for the doors. ....................................................................................................................10

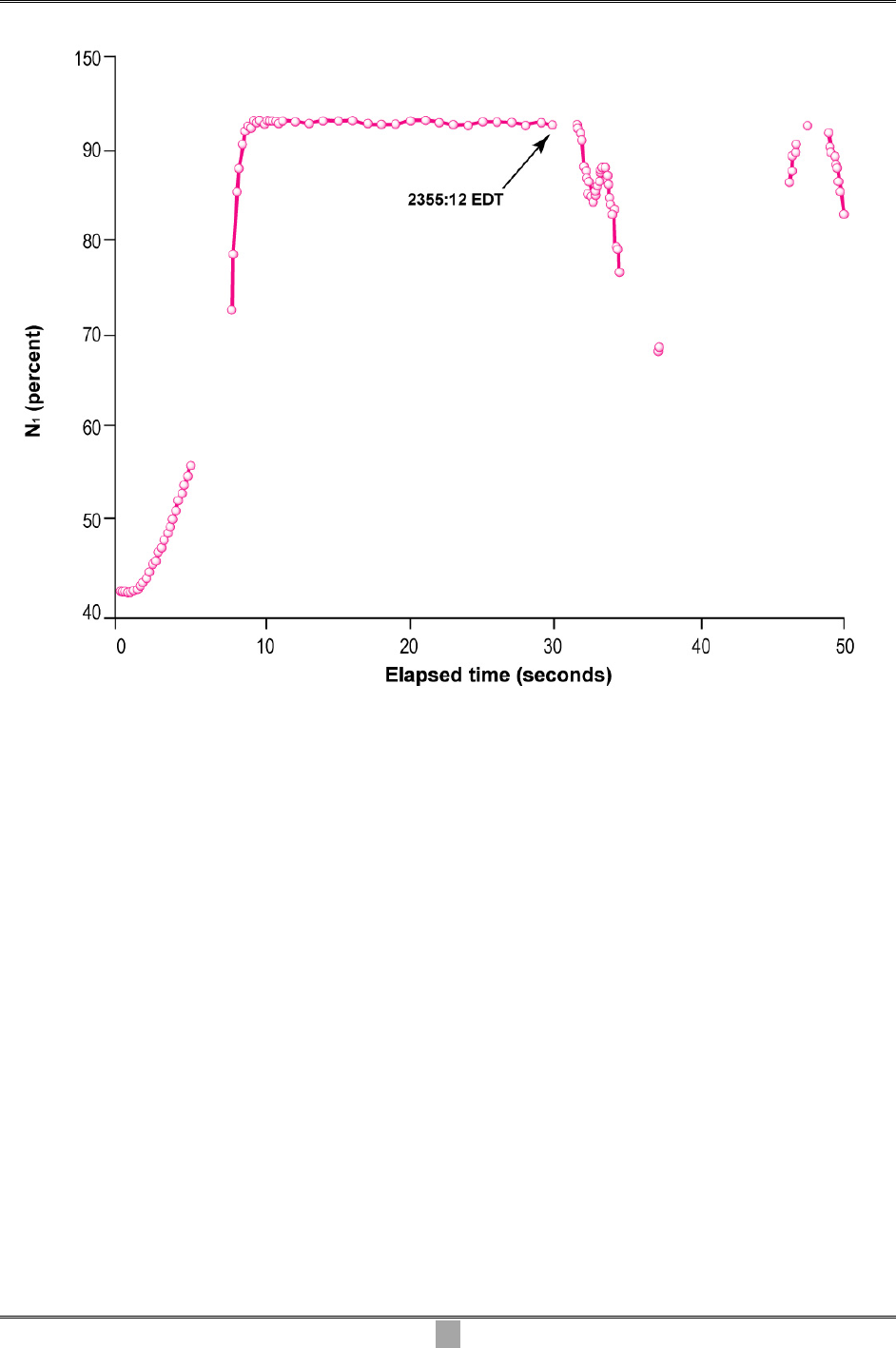

Figure 4. Engine N

1

calculated as a function of elapsed time into the takeoff roll (time of the

start of the loud rumbling sound is shown). ...................................................................................18

Figure 5. Airplane ground speed calculated as a function of elapsed time into the takeoff roll

(time of the start of the loud rumbling sound is shown). ...............................................................19

Figure 6. Map of Columbia Metropolitan Airport showing integrated sound spectrum data,

cockpit voice recorder comments, and wreckage locations plotted. ..............................................20

Figure 7. Reconstruction of the right outboard main landing gear tire showing outboard sidewall

damage. Arrows depict the generally uniform location of the damage. ........................................22

Figure 8. Inboard aft corner of the left main landing gear wheel well for the Learjet 45 (left) and

the inboard after corner of the right main landing gear wheel well for the Learjet 60 (right). ......30

iv

NTSB Aircraft Accident Report

Acronyms and Abbreviations

AC advisory circular

AFM airplane flight manual

AMM aircraft maintenance manual

ARFF aircraft rescue and firefighting

ARP aerospace recommended practice

ASRS Aviation Safety Reporting System

ATIS automatic terminal information service

ATP airline transport pilot

AW advisory wire

CAE Columbia Metropolitan Airport

CAM cockpit area microphone

CFR Code of Federal Regulations

CRM crew resource management

CSN cycles since new

CVR cockpit voice recorder

DER designated engineering representative

EEC electronic engine control

EUROCAE European Organization for Civil Aviation Equipment

FAA Federal Aviation Administration

v

NTSB Aircraft Accident Report

FADEC full authority digital electronic control

FBO fixed-base operator

FDR flight data recorder

FR Federal Register

FSI FlightSafety International

KIAS knots indicated airspeed

kts knots

MLG main landing gear

msl mean sea level

N

1

engine fan speed

NPRM notice of proposed rulemaking

NTSB National Transportation Safety Board

P/N part number

PIC pilot-in-command

POI principal operations inspector

psi pounds per square inch

QRH quick reference handbook

QTR qualification test report

RSA runway safety area

RTO rejected takeoff

vi

NTSB Aircraft Accident Report

RVDT rotary variable differential transformer

S/N serial number

SAFO safety alert for operators

SB service bulletin

SIC second-in-command

SIR special investigation report

SMS safety management system

TC type certificate

TCDS type certificate data sheet

TEB Teterboro Airport

TFM temporary flight manual

TLA thrust lever angle

TPMS tire pressure monitoring system

TR temporary revision

TSO technical standard order

V

1

takeoff decision speed

V

2

takeoff safety speed

V

r

rotation speed

VOR very high frequency omnidirectional radio range

vii

NTSB Aircraft Accident Report

viii

Executive Summary

On September 19, 2008, about 2353 eastern daylight time, a Bombardier Learjet

Model 60, N999LJ, owned by Inter Travel and Services, Inc., and operated by Global Exec

Aviation, overran runway 11 during a rejected takeoff at Columbia Metropolitan Airport,

Columbia, South Carolina. The captain, the first officer, and two passengers were killed; two

other passengers were seriously injured. The nonscheduled domestic passenger flight to Van

Nuys, California, was operated under 14 Code of Federal Regulations Part 135. Visual

meteorological conditions prevailed, and an instrument flight rules flight plan was filed.

The National Transportation Safety Board determines that the probable cause of this

accident was the operator’s inadequate maintenance of the airplane’s tires, which resulted in

multiple tire failures during takeoff roll due to severe underinflation, and the captain’s execution

of a rejected takeoff (RTO) after V

1

, which was inconsistent with her training and standard

operating procedures.

Contributing to the accident were (1) deficiencies in Learjet’s design of and the Federal

Aviation Administration’s (FAA) certification of the Learjet Model 60’s thrust reverser system,

which permitted the failure of critical systems in the wheel well area to result in uncommanded

forward thrust that increased the severity of the accident; (2) the inadequacy of Learjet’s safety

analysis and the FAA’s review of it, which failed to detect and correct the thrust reverser and

wheel well design deficiencies after a 2001 uncommanded forward thrust accident;

(3) inadequate industry training standards for flight crews in tire failure scenarios; and (4) the

flight crew’s poor crew resource management (CRM).

The safety issues discussed in this report focus on criticality of proper aircraft tire

inflation; maintenance requirements and manual revisions for tire pressure check intervals; tire

pressure monitoring systems; airplane thrust reverser system design deficiencies; inadequate

system safety analyses by the FAA and Learjet; inadequate level of safety in the certification of

changed aeronautical products; flight crew training for tire failure events; flight crew

performance, including the captain’s action to initiate an RTO after V

1

, the captain’s experience,

and CRM; and considerations for tire certification criteria. Safety recommendations concerning

these issues are addressed to the FAA.

NTSB Aircraft Accident Report

1

1. Factual Information

1.1 History of Flight

On September 19, 2008, about 2353 eastern daylight time,

1

a Bombardier Learjet

Model 60 (Learjet 60),

2

N999LJ, owned by Inter Travel and Services, Inc., and operated by

Global Exec Aviation, overran runway 11 during a rejected takeoff (RTO)

3

at Columbia

Metropolitan Airport (CAE), Columbia, South Carolina. The captain, the first officer, and two

passengers were killed; two other passengers were seriously injured. The nonscheduled domestic

passenger flight to Van Nuys, California, was operated under 14 Code of Federal Regulations

(CFR) Part 135. Visual meteorological conditions prevailed, and an instrument flight rules flight

plan was filed.

Review of the cockpit voice recorder (CVR) transcript revealed that the flight crew

received clearance instructions from the CAE ground controller at 2347:04 to taxi from the

northeast fixed-base operator’s (FBO) parking ramp to runway 11. After a short discussion with

the first officer about which way to turn,

4

the captain, who was the pilot flying, turned the

airplane left onto taxiway U. The controller provided an amended taxi clearance after noticing

that the airplane had turned the wrong way.

5

The flight crew followed the amended taxi

clearance, which involved back-taxiing the airplane on runway 11 and performing a 180° turn on

the runway to position the airplane for takeoff.

At 2351:22, the captain briefed the RTO procedure and stated, “we’ve got plenty of

runway so we’ll abort for anything below eighty knots [kts] after V-one and before V-two

[6]

engine failure fire malfunction loss of directional control all the big things after V-two we’ll go

1

All times in this report are eastern daylight time unless otherwise noted and based on a 24-hour clock.

2

Learjet engineering and certification documents refer to the airplane as Learjet Model 60 or L60. For brevity

and consistency, this report refers to the Learjet Model 60 as “Learjet 60.”

3

An RTO may also be referred to as an aborted takeoff in some publications.

4

The clearance was to taxi via taxiway U and cross the approach end of runway 23 to taxiway N, then taxiway

A. The first officer replied to the controller, “okay Uniform November Alpha ah to one one.” The captain stated to

the first officer, “and hold short of two two I think it was,” and the first officer replied, “I think he said…we could

cross it.” The captain stated, “oh did he?” and then asked, “and we’re going right outta here, correct?” The first

officer replied, “ah well I think we have to go left outta here don’t we?”

5

The controller stated that construction at the airport made it confusing for pilots to taxi. He indicated that the

accident flight crew’s initial taxi clearance would have required the crew to turn the airplane away from the takeoff

runway, which the controller stated went “against normal.”

6

According to 14 CFR 1.2, V

1

is the maximum speed in the takeoff at which the pilot must take the first action

(such as applying brakes, reducing thrust, or deploying speed brakes) to stop the airplane within the accelerate-stop

distance, which is a calculated distance defined in 14 CFR 25.109. V

1

is also the minimum speed in the takeoff at

which, after a failure of an airplane’s critical engine, the pilot can continue the takeoff and achieve the required

height above the takeoff surface within the takeoff distance. According to 14 CFR 25.107, V

2

is the takeoff safety

speed that must provide at least a minimum specified climb gradient in the event of a loss of power in one engine.

NTSB Aircraft Accident Report

2

ahead and take it into the air treat it as an in-flight emergency.”

7

The first officer replied,

“correct.” The captain asked if the first officer had any questions, and the first officer asked,

“reference the ah between eighty and ah V-one you’re only ah aborting for the fire failure loss of

directional control?” The captain replied, “yes,” then added, “or an inadvertent thrust-, ah, T-R

[thrust reverser] deployment.” The first officer then stated, “that will ah cause the loss of

directional control I guess,” to which the captain replied, “exactly hah they go together.” The

first officer later stated, “well eh if the runway is long I abort but if it’s short I kinda do different

briefing depending on what the length of the runway is but we’re pretty heavy so it’s probably

not a bad idea.” The CVR transcript indicated that the flight crew continued performing

pretakeoff checklist items and that the captain requested wind information.

8

The captain initiated the takeoff roll, and, at 2355:00.1,

9

the first officer stated, “eighty

knots. Crosscheck,” to which the captain replied, “check.” At 2355:10.5, the first officer

reported, “V-one.” About 1.5 seconds later, the CVR captured the beginning of a loud rumbling

sound. Postaccident sound spectrum and airplane performance studies

10

indicated that the

airplane’s position on the runway at the onset of the loud rumbling sound corresponded with the

location where the first main landing gear (MLG) tire fragments were found. Four-tenths second

after the beginning of the loud rumbling sound, the first officer stated, “go,” the captain stated

something unintelligible, and, at 2355:13.0, the first officer stated, “go go go.” The CVR

recorded a sound similar to a metallic click, and, at 2355:14.0, the captain stated, “go?”

Postaccident sound spectrum and airplane performance studies estimated that, about this time,

the airplane’s ground speed reached a peak of about 144 kts. The first officer then stated, “no?

ar- alright. Get ah what the [expletive] was that?” The CVR recorded another metallic click

sound, and, at 2355:17.0, the captain stated, “I don’t know. We’re not goin’ though.”

At 2355:18.4, another metallic click sound was recorded, and, at 2355:19.5, the captain

stated, “full out.” Postaccident performance studies indicated that the airplane was decelerating.

Within 1 second, the CVR captured a sound consistent with the application of wheel braking,

and, at 2355:21.6, the CVR captured a sound consistent with the nosewheel steering disconnect

warning tone. Postaccident performance studies indicated that the airplane had then accelerated.

About 7 seconds later, the first officer stated, “shut ’em off,” and, at 2355:32.4, the first officer

stated, “they’re shut off they’re shut off.” At 2355:36.0, the first officer made a radio

transmission on the CAE tower control frequency, saying, “roll the equipment we’re goin’ off

the end.” The CVR recording ended at 2355:41.1.

A controller in the CAE tower who observed the airplane’s takeoff roll reported that the

beginning of the takeoff roll appeared normal but that, when the airplane was part way down the

runway, sparks appeared that seemed to be coming from the airplane’s right MLG. One of the

7

The captain’s briefing of the RTO criteria was inconsistent with Global Exec Aviation’s training manual,

which is discussed in section 1.17.2.1.

8

At 2354:27, the captain asked the first officer to request a wind check from the controller. The controller

stated, “wind zero seven zero at eight gust one four.” The captain asked the first officer, “zero one zero at eight?”

The first officer replied, “ah huh.” The captain then stated, “’kay so pretty much straight down.” Runway 11 has a

magnetic heading of 110°.

9

Times related to the takeoff sequence are reported to tenths of 1 second because of the speed at which events

occurred.

10

For further information, see sections 1.16.1 and 1.16.2.

NTSB Aircraft Accident Report

two surviving passengers stated that, during the takeoff roll, the airplane was shifting and

swaying back and forth all the way down the runway and that the airplane felt “out of control”

from the start. The other surviving passenger reported that the airplane felt as if it blew a tire and

that the airplane leaned to the right “almost like a wing had touched the ground.”

The controller observed that the airplane went straight off the end of the runway. The

airplane passed through the 1,000-foot runway safety area (RSA), struck airport lighting and

navigation antennas, and descended a steep downhill slope before striking a lighting pole and the

perimeter fence. The airplane then struck a concrete highway marker post, crossed a five-lane

road, and struck a second concrete post and an embankment on the far side of the road. The

controller stated that, when the airplane struck the hill, the airplane stopped and exploded into a

fireball. Both passengers stated that the nose of the airplane went up and down at least twice

before final impact. Debris from all four MLG tires was found on the runway.

1.2 Injuries to Persons

Table. Injury Chart

Injuries Flight Crew Cabin Crew Passengers Other Total

Fatal

2 0 2 0 4

Serious

0 0 2 0 2

Minor

0 0 0 0 0

None

0 0 0 0 0

Total

2 0 4 0 6

1.3 Damage to Airplane

The airplane was destroyed by impact forces and the postcrash fire.

1.4 Other Damage

Damage to airport property included some of the runway approach lighting, a localizer

antenna array, and the airport perimeter fence. Concrete roadway right-of-way markers and a

five-lane asphalt road were also damaged.

1.5 Personnel Information

The captain was hired by Global Exec Aviation on January 4, 2008, and the first officer

was hired on August 8, 2008. According to Global Exec Aviation’s director of operations, the

accident flight was the crewmembers’ second flight of the day, and they had previously flown

together twice.

3

NTSB Aircraft Accident Report

4

1.5.1 Captain

The captain, age 31, held an airline transport pilot (ATP) certificate for multiengine land

airplanes with type ratings for Cessna CE-500 (issued on June 18, 2005), Learjet 60 (issued on

October 25, 2007), and Cessna CE-650 (issued on January 19, 2008) airplanes.

11

She held a

first-class airman medical certificate issued April 29, 2008, with the limitation, “holder shall

wear corrective lenses.”

According to Global Exec Aviation employment records, the captain had accumulated

about 3,140 hours total flight time, including about 2,040 hours pilot-in-command (PIC) time.

She had accumulated about 35 hours in the Learjet 60 (about 8 hours of which were as PIC) and

about 118 hours in the Cessna CE-650 (which were accumulated at Global Exec Aviation).

Before the 2-day trip pairing that included the accident flight, the captain’s most recent

experience as PIC of a Learjet 60 was on August 16, 2008. In the 30 days before the accident, the

captain had accumulated about 19 hours as second-in-command (SIC) in the Learjet 60 and

about 15 hours as PIC in the Cessna CE-650. In the 90 days, 30 days, and 24 hours preceding the

accident, the captain had logged about 67, 36, and 1.5 hours, respectively.

The captain completed Global Exec Aviation’s initial new-hire training on January 4,

2008. Global Exec Aviation’s director of operations stated that the captain came to the company

with excellent references and had flown with and been recommended by a previous Federal

Aviation Administration (FAA) principal operations inspector (POI) for the company. The

director of operations stated that, because of the captain’s references, the company did not give

the captain a checkride in a simulator, even though the company typically gave a checkride to

other potential new hires.

The captain’s most recent recurrent simulator training was completed at a FlightSafety

International (FSI) training facility on August 13, 2008, and her most recent recurrent ground

training was completed on August 16, 2008. The captain’s most recent line check was completed

on May 6, 2008, and her most recent Learjet 60 proficiency check was completed on August 14,

2008. The evaluator who conducted the Learjet 60 proficiency check stated that the captain

performed “very much” within standards and that the outcome of the checkride was never in

doubt. He stated that the captain displayed good crew resource management (CRM) skills and

had good command of the airplane.

Another Learjet 60 instructor who provided recurrent ground and simulator training to the

captain at FSI described her as meticulous with good organizational skills. He recalled that,

during training, the captain told him that she had not been in the Learjet 60 for some time; he

stated that her first day of simulator training was a little rough during basic air work but that, by

the end of that session, the captain was doing well. The instructor reported that the captain’s

second and third day of training went very well. He stated that his notes for the second day

indicated “excellent CRM” and that he does not give that rating to many people. He stated that

11

She also held second-in-command privileges for Cessna CE-560XL airplanes; a flight instructor certificate

for instrument, single-engine, and multiengine land airplanes; commercial privileges for single-engine land

airplanes; private privileges for single-engine seaplanes; and an aircraft dispatcher certificate.

NTSB Aircraft Accident Report

5

the training included such abnormal scenarios as V

1

cuts and RTOs with an engine failure or a

thrust reverser unlock.

Global Exec Aviation’s director of operations, who had trained with the captain and had

flown about 30 hours with her, described the captain as “laid back,” which he considered

“typical of a less experienced captain.” He described her decision-making skills as excellent and

conservative. He stated that he would work with her on being more vocal in her command

authority but that she was “above normal” for a new captain.

A review of FAA records found no previous accidents, incidents, or enforcement actions.

FAA records indicated that the captain received a notice of disapproval on August 11, 2006, for a

practical test for the ATP certificate because of unsatisfactory performance in the nonprecision

approach and circle-to-land procedures. She retested the same day and passed. On April 11,

1997, when the captain was a private pilot with about 192 total flight hours, she received a notice

of disapproval for the practical test for the airplane instrument rating because of unsatisfactory

performance of partial-panel very high frequency omnidirectional radio range (VOR) instrument

approach procedures and instrument landing system instrument approach procedures. She was

retested on April 14, 1997, and received a second notice of disapproval because of unsatisfactory

performance of partial-panel VOR instrument approach procedures. She was retested on May 28,

1997, and passed. On November 14, 1997, when the captain had accrued about 252 total flight

hours, she received a notice of disapproval for a practical test for the commercial airplane

multiengine land certificate because of unsatisfactory knowledge of the national airspace system

and airplane performance and limitations. (She subsequently passed the checkride for private

pilot privileges for multiengine land airplanes on December 6, 1997, and she passed the

checkride for the commercial certificate for multiengine land airplanes on September 1, 2004.

12

)

1.5.2 First Officer

The first officer, age 52, held an ATP certificate for multiengine land airplanes with type

ratings for Learjet 60 (issued on March 1, 2007) and Cessna CE-500 airplanes.

13

He held a

first-class airman medical certificate issued July 18, 2008, with the limitations “must wear

corrective lenses” and “possess glasses for near/intermediate vision.” According to employment

records from Global Exec Aviation and estimates from another employer

14

and a previous

employer, the first officer had accumulated about 8,200 hours total flight time, including about

7,500 hours PIC time and about 300 hours in Learjet 60 airplanes (about 108 hours of which

were as SIC). In the 90 days, 30 days, and 24 hours preceding the accident, the first officer

logged about 42, 34, and 1.5 hours, respectively.

12

According to the captain’s résumé, in 1997, she was attending college and was not working in an aviation

field that would require a commercial multiengine certificate. She subsequently gained flight experience and worked

as a flight instructor in the years before her successful retest in 2004.

13

He also held commercial privileges for single-engine land airplanes, rotorcraft/helicopters, and instrument

helicopters.

14

The first officer also began flying for another operator in August 2008. Global Exec Aviation’s director of

operations stated that he thought that the first officer had accepted a full-time position with another operator but that

he was unsure of which one.

NTSB Aircraft Accident Report

6

The first officer completed Global Exec Aviation’s initial new-hire training on August 8,

2008. His previous employer, also a Part 135 operator, provided him with Learjet 60 flight

training and his most recent Learjet 60 proficiency check, which was completed on March 13,

2008.

15

Global Exec Aviation’s director of operations stated that the first officer was hired as a

part-time pilot. A review of FAA records found no previous accidents, incidents, enforcement

actions, or notices of disapproval.

Global Exec Aviation’s director of operations had flown about 5 hours with the first

officer and described him as a well-experienced pilot with excellent piloting skills. He stated that

the first officer had good CRM skills and had no problem speaking up but that he was not overly

assertive.

1.5.3 Flight Crew’s 72-Hour History

Review of airline travel, cellular telephone, hotel, and company records provided

information about the captain’s and the first officer’s nonwork activities during the 72 hours

before the accident. These records revealed that, on Wednesday, September 17, 2008, both the

captain and the first officer were passengers aboard a commercial flight that departed Long

Beach, California, about 1238 Pacific daylight time en route to New York. They checked into

hotel rooms in Secaucus, New Jersey, about 2200, and each requested hotel wake-up calls for

about 0800 the next morning. Based on their respective telephone records, the captain had the

potential for 6 hours of sleep, and the first officer had the potential for 7 hours of sleep, that

night. The first officer’s wife, who had communicated with him via telephone and text

messaging, recalled that he had told her that noise at the hotel made it difficult to sleep.

On Thursday, September 18, 2008, both pilots left the hotel about 1000, taking the hotel

shuttle to Teterboro Airport (TEB), Teterboro, New Jersey, where the accident airplane was

parked. About 1200, they conducted a 48-minute test flight in the accident airplane to ensure that

maintenance on a high-pressure bleed valve was effective.

16

About 1400, both the captain and

the first officer checked into their rooms at a different hotel in Secaucus and were off duty until

the next day. Based on their respective cellular telephone records, the captain had the potential

for 7.5 to 9.5 hours of sleep, and the first officer had the potential for 9.75 hours of sleep, during

the night before the accident.

On Friday, September 19, 2008 (the day of the accident), telephone activity for the

captain showed numerous telephone calls and text messages, leaving three 1-hour uninterrupted

periods. Telephone activity for the first officer indicated that he had one 1-hour and one 2-hour

periods of uninterrupted time. Both the captain and the first officer checked out of the hotel

about 2018 and traveled to TEB. They departed TEB in the accident airplane about 2142 and

arrived at the Columbia Aviation ramp at CAE about 2310 to pick up the passengers.

15

Global Exec Aviation and the FAA accepted the training performed under his previous employer because

both companies used the same training program and facility. The FAA can accept such training instead of training

provided by the current employer if the FAA determines that the previous training was sufficient.

16

The accident airplane had been at TEB since September 12, 2008, for maintenance after the valve became

stuck in the open position during a flight.

NTSB Aircraft Accident Report

7

1.6 Airplane Information

The accident airplane was powered by two Pratt & Whitney Canada PW305A

high-bypass turbofan engines, each of which was rated at a maximum 4,600 pounds of thrust

with a maximum nontransient forward engine fan speed (N

1

) of 10,820 rpm, or 102 percent. The

airplane’s initial airworthiness certificate was dated December 14, 2006, and the airplane was

configured with a seating capacity for two crewmembers and eight passengers. The accident

airplane’s empty weight was 14,755 pounds, its maximum ramp weight was 23,750 pounds, and

its maximum takeoff weight was 23,500 pounds. According to performance calculations

provided by Bombardier Learjet, given the accident flight conditions, V

1

would have been

136 kts indicated airspeed (KIAS),

17

V

r

(rotation speed) would have been 145 KIAS, and V

2

would have been 153 KIAS.

According to logbook information dated September 16, 2008, the airplane had

accumulated 106 hours and 121 cycles since new (CSN). At the time of the accident, the airplane

had accumulated an estimated 108.5 hours and 123 CSN.

1.6.1 Main Landing Gear Tires

The airplane was equipped with dual wheel and tire assemblies at each MLG position.

Each MLG tire was a Goodyear Flight Eagle, part number (P/N) 178K43-1, size 17.5 x 5.75-8.

18

For use on the Learjet 60, the rated tire inflation pressure

19

was 220 pounds per square inch (psi).

Applicable tire certification requirements are specified in 14 CFR 25.733 and FAA Technical

Standard Order (TSO) TSO-C62c.

20

TSO-C62c specified various tire performance criteria, one

of which was a maximum allowable air pressure loss of 5 percent per day for an airplane tire

under normal operating circumstances. According to the Goodyear Qualification Test Report

(QTR) 461B-3044-TL, the Goodyear Flight Eagle tire documented a daily pressure loss of about

2.2 percent.

Maintenance logs indicated that all four MLG tires were new when installed in

December 2007 and had accumulated a total of 20 landings at the time of the accident. Flight

history records showed that the airplane had flown 5 days during the 12-day period that preceded

the accident. Interviews with personnel from all facilities that handled the accident airplane

during that time period revealed that none had serviced or received a request to service the MLG

tires. Global Exec Aviation’s director of maintenance estimated that the tire pressures may not

have been checked for about 3 weeks before the accident.

17

KIAS refers to the airplane’s speed as shown on the airspeed indicator.

18

For the purpose of this report, “Goodyear Flight Eagle tire” refers to tire P/N 178K43-1, size 17.5 x 5.75-8,

as specified for the Learjet 60.

19

Rated pressure is the maximum inflation pressure to match the tire’s load rating. Aircraft tire pressures are

given for an unloaded tire; when the rated load is applied to the tire, the pressure increases by 4 percent as a result of

a reduction in air volume. According to Learjet data, the allowable MLG tire pressure range for the Learjet 60

(based on its maximum takeoff weight of 23,500 pounds) would be 209 to 219 pounds per square inch gauge (gauge

pressure).

20

TSO-C62c was in effect at the time of certification; the current version is TSO-C62e, issued on September

29, 2006.

NTSB Aircraft Accident Report

The Learjet 60 Aircraft Maintenance Manual (AMM) contained the minimum

maintenance requirements for continued airworthiness in accordance with applicable regulations.

Chapter 5 of the AMM, the contents of which related to the intervals for scheduled inspections,

stated that the Learjet inspection program “also contains other inspections and individual

stand-alone inspection checks, which must be accomplished at the specified intervals.” Chapter 5

referenced tire pressure inspections under “Inspection Phase A5.” The A5 inspection, which is

due at 300-hour intervals, included Inspection Reference Number P1210055, which stated,

“Nose and Main Tires – Check for proper inflation. (Refer to [chapter] 12-10-05).”

The contents of chapter 12 of the AMM related to technical specifications and

descriptions of how to perform various maintenance tasks. Chapter 12-10-05, pages 301 and 302,

contained the following guidance:

Important inflation practices and tips are as follows: … Measure the cold tire

pressure before the first flight of every day or every 10 day[s] on in-service tires

[that] are not in use.… Do not underinflate the tire. An underinflated tire

generally cannot be detected visually.

The AMM indicated that a tire should be replaced if found to have operated at an inflation

pressure loss of 15 percent.

Other guidance calling for daily or regular checks of tire pressure was contained in a

Learjet maintenance publication, Aircraft Tire Care and Maintenance, dated September 2001; a

Learjet product support publication, Everyday Maintenance of Tires and Brakes, dated April 10,

2007; FAA Advisory Circular (AC) AC 20-97B, Aircraft Tire Maintenance and Operational

Practices; and several Goodyear publications, including Goodyear Information Report 97001,

Learjet Tire Maintenance, dated January 9, 1997, and an operator letter dated March 1999

referring to the availability of Goodyear’s Comprehensive Guide to Aircraft Tire Care and

Maintenance.

As shown in figure 1 below, to check tire pressures on the Learjet 60, the person

performing the check must crouch or crawl under the wing of the airplane to gain access to the

MLG tire pressure valves. The landing gear doors may conceal the valves for the outboard tires,

requiring a person to lie on the ground to gain access.

8

NTSB Aircraft Accident Report

Figure 1. Learjet factory technician checking inboard tire pressure (left image) and

outboard tire pressure (right image).

1.6.2 Engine Power Control and Thrust Reverser System Control

The Learjet 60’s control levers for commanding engine power for forward thrust are

located on the cockpit pedestal. The level of engine power (measured as N

1

) commanded by the

pilot’s positioning of the thrust levers for forward thrust is communicated electronically to the

engine control components mounted on

each engine. The Learjet 60 has no

mechanical or cable-actuated connection

between the cockpit thrust levers and the

engines.

The airplane’s thrust reverser

system, which is designed to help stop the

airplane on the ground, is also

electronically controlled. The thrust

reverser system responds to the pilot’s

positioning of the thrust reverser levers

(also known as “piggyback” levers because

they are located on top of the thrust levers)

by using electronic signals to command

reverse thrust functions. See figure 2 (at

right) for the captain’s side view of Learjet

60 thrust levers and thrust reverser levers.

reverser system responds to the pilot’s

positioning of the thrust reverser levers

(also known as “piggyback” levers because

they are located on top of the thrust levers)

by using electronic signals to command

reverse thrust functions. See figure 2 (at

right) for the captain’s side view of Learjet

60 thrust levers and thrust reverser levers.

The Learjet 60’s thrust reversers

are designed with two half-shell doors on

each engine that form the engine’s aft

nacelle when stowed (forward thrust

configuration). When deployed (reverse

thrust configuration), the thrust reverser

doors redirect the flow of engine fan air

and exhaust gases forward to provide a

The Learjet 60’s thrust reversers

are designed with two half-shell doors on

each engine that form the engine’s aft

nacelle when stowed (forward thrust

configuration). When deployed (reverse

thrust configuration), the thrust reverser

doors redirect the flow of engine fan air

and exhaust gases forward to provide a

Figure 2. Captain's side view of Learjet 60 thrust

levers (at idle) and thrust reverser (piggyback) levers.

To illustrate lever movement, one thrust reverser lever

is in the stowed position, and the other is lifted to

command reverse thrust (arrow shows direction lever

moves when lifted from the stowed position).

9

NTSB Aircraft Accident Report

10

deceleration force to assist with ground braking. (See figure 3 below, which depicts a Learjet 60

with thrust reversers deployed.) Although the use of reverse thrust can reduce the distance

needed to stop the airplane, most of the stopping power is provided by the wheel brakes.

21

Both the thrust levers and the thrust reverser (piggyback) levers share some common

mechanical components in the cockpit pedestal that move whenever a pilot manipulates either

the thrust levers or the thrust reverser levers. The shared components depend on microswitches

to detect which levers the pilot is using for commanding either forward or reverse thrust. (The

following two sections describe the shared components and the basic system functions for

forward and reverse thrust during normal operations; section 1.6.2.3 describes the fail-safe logic

criteria and system responses to detected anomalies.)

21

The FAA’s master minimum equipment list for the Learjet 60 (upon which operators’ minimum equipment

lists are based) allows an operator to fly the airplane with inoperative thrust reversers for up to 10 days, during

which time a maintenance lockout pin is installed in the reversers to prevent use.

Figure 3. Learjet 60 with thrust reversers deployed. The dotted yellow lines show the stowed

position for the doors.

NTSB Aircraft Accident Report

11

1.6.2.1 Commanding Forward Thrust

To command forward thrust, a pilot positions the cockpit thrust levers (one per engine) to

a desired engine power setting (such as takeoff, maximum continuous thrust, or cruise power).

As the pilot moves the thrust levers, a mechanical linkage on each thrust lever rotates the input

shaft on a rotary variable differential transformer (RVDT) in the cockpit pedestal for each lever.

As the RVDTs’ input shafts rotate, each RVDT electronically provides information about the

changing thrust lever angle (TLA) to the electronic engine control (EEC) computer for the

corresponding engine. The EECs interpret the TLA information and provide corresponding

electronic signals to each engine’s full authority digital electronic control (FADEC)

components.

22

Based on the signals received from the EECs, the FADEC components, which

perform functions including thrust management and compressor surge control, regulate engine

output to provide the level of engine power commanded by the pilot. In the case in which the

EECs provide the logic signals that forward thrust has been commanded, the FADEC

components regulate engine power according to the forward thrust power schedule.

1.6.2.2 Commanding Reverse Thrust

To command reverse thrust, a pilot positions the engine power levers to idle power, then

lifts the thrust reverser (piggyback) levers to the deploy position. When the thrust reverser levers

are lifted to the deploy position, a mechanical linkage on each lever (the same linkage used by

each thrust lever when forward thrust is commanded) rotates the input shaft on each respective

RVDT; microswitches (one for each thrust reverser lever) detect that the reverser levers are lifted

and send an electronic request for the thrust reversers to deploy.

While the thrust reverser doors on both engines begin to move from stowed toward the

deployed position, balk solenoids in the throttle quadrant (one for each lever) momentarily

prevent the pilot from moving the thrust reverser levers further until the thrust reversers fully

deploy. Once the doors are fully deployed, each balk solenoid releases, allowing the pilot to

further lift the thrust reverser levers to command increased reverse thrust.

The EECs respond to the pilot’s movement of the thrust reverser levers by signaling the

FADEC components to set engine power in accordance with the reverse thrust power schedule.

The reverse thrust power schedule is a function of both TLA (set by the pilot through positioning

of the reverse thrust levers to command any amount of reverse thrust up to full reverse thrust)

and the airplane’s indicated airspeed when less than 100 kts. Slower indicated airspeed will

result in less thrust.

23

22

According to Pratt & Whitney Canada, the FADEC is a dual-channel system made of several components to

control the engine’s thrust. The main control system components are the thrust lever, EEC, and the hydromechanical

fuel metering unit. The FADEC system regulates each engine’s high-pressure rotor speed (N

2

) and low-rotor (fan)

speed (N

1

) in response to the pilot-operated TLA, ambient conditions, other pilot-selected inputs, and aircraft

discrete inputs.

23

According to the Pratt & Whitney Canada PW305 Customer Training Manual, engine power provided for

reverse thrust for an airplane traveling at 100 kts would be about 85 percent of takeoff N

1

, whereas engine power for

an airplane traveling 0 to 40 kts would be about 50 percent of takeoff N

1

.

NTSB Aircraft Accident Report

12

1.6.2.3 Thrust Reverser System Logic Criteria

The thrust reverser system requires specific input from various sensors on the airplane,

which provide input into the logic control functions that prevent certain operations when specific

criteria are not met. The thrust reverser system logic criteria are designed to protect against

inadvertent thrust reverser deployment during flight and to prevent the engines from producing

high levels of thrust while the reverser doors are in transit.

For the thrust reverser doors on each engine to fully deploy when commanded and to

remain deployed, the EECs must receive input from the squat switches, which are sensors

mounted on each MLG assembly, signaling that the airplane is on the ground.

24

In addition, each

engine’s thrust reverser doors must fully open to change the electrical state of the switches for

the balk solenoids to release the thrust reverser levers. In addition, the thrust reverser levers’

microswitches (located in the cockpit pedestal with each respective RVDT) must indicate that

the reverser levers are lifted before the EECs will signal the FADEC components to use the

reverse thrust engine power schedule.

In the event of a scenario in which almost any of the thrust reverser logic requirements

are not met, the thrust reversers are designed to stow. Learjet engineering personnel indicated

that the uncommanded stowage of the thrust reversers in the event of any system loss or

malfunction is part of a fail-safe design that ensures that a system anomaly cannot result in a

thrust reverser deployment in flight, which could adversely affect the airplane’s controllability.

The design is intended to reduce the pilot’s emergency procedures workload and prevent

potential mistakes that could exacerbate an abnormal situation.

25

1.7 Meteorological Information

Automatic terminal information service (ATIS) information V (victor) was current at the

time of the accident. According to the CVR transcript, the first officer advised the ground

controller before taxi that the crew had obtained ATIS V, which indicated that winds were from

060° at 10 kts, visibility was 10 miles with clear skies below 12,000 feet above mean sea level

(msl), the temperature was 21° C, the dew point was 13° C, and the altimeter setting was

30.23 inches of mercury.

1.8 Aids to Navigation

No deficiencies with navigational aids were noted.

24

The squat switches signal “ground mode” upon sensing that the MLG is partially compressed to support the

airplane’s weight.

25

Both Learjet and FAA personnel noted that designing the thrust reversers to fail to the stow position prevents

a pilot from having to perform the procedures of isolating which engine had a faulty thrust reverser, correctly

increasing thrust on the opposing engine to counteract the other’s reverse thrust, and then shutting down the engine

with the faulty thrust reverser. In multiengine airplanes, numerous accidents have occurred when pilots identified

and shut down the wrong engine.

NTSB Aircraft Accident Report

13

1.9 Communications

No ground or airplane communications equipment deficiencies were noted.

1.10 Airport Information

CAE is located about 5 miles southwest of Columbia at an elevation of about 236 feet

msl. Runway 11/29, which has a grooved asphalt surface, is 8,601 feet long and 150 feet wide.

The RSA beyond the departure end of runway 11 is 1,000 feet long and 500 feet wide. At the

time of the accident, several taxiways and runway 5/23 were closed for construction. Runway

and taxiway closure information was available in Notice to Airmen 08-75 and was included in

the ATIS V broadcast.

CAE is certificated under 14 CFR Part 139 and maintains aircraft rescue and firefighting

(ARFF) capabilities at index C.

26

At the time of the accident, CAE had four firefighting

personnel on duty 24 hours a day and three ARFF vehicles (Redbird 6, 9, and 10). Each vehicle

was a 1500-series crash truck that carried at least 1,500 gallons of water and 200 gallons of foam

concentrate. Redbird 10 also carried 700 pounds of dry chemical agent.

1.11 Flight Recorders

The airplane was equipped with a Universal model 1603-02-12 CVR, which is a

solid-state unit that records 2 hours of digital audio information. Examination of the CVR

showed structural and fire damage on the outer case. Removal of the damaged outer case

exposed the inner crash-protected memory case, which showed no structural or fire damage.

Download of the digital information at the National Transportation Safety Board’s

(NTSB) laboratory in Washington, D.C., revealed that the CVR captured both a two-channel

recording of the last 2 hours of operation and a separate four-channel recording of the last

30 minutes of operation. The 2-hour recording captured one channel of poor-quality

27

audio

information from the cockpit area microphone (CAM) and one channel of good-quality

28

audio

information from the captain’s and the first officer’s audio panels combined. The 30-minute

recording captured good-quality audio information from the captain and the first officer and

26

CAE is an index C airport based on five or more average daily departures of aircraft having a length of at

least 126 feet but less than 159 feet. To meet index C capabilities, two or three ARFF vehicles are required that

contain a total of 3,000 gallons of water and commensurate quantities of aqueous film-forming foam. In addition,

ARFF apparatus must carry either 500 pounds of sodium-based dry chemical, halon 1211, clean agent, or 450

pounds of potassium-based dry chemical agent.

27

The NTSB uses five categories to classify the levels of CVR recording quality: excellent, good, fair, poor,

and unusable. A poor-quality recording is characterized by fragmented phrases and conversations, and extensive

passages of conversations may be missing or unintelligible.

28

A good-quality recording is characterized by crew conversations that are easily and accurately

understandable with only a few words that are unintelligible.

NTSB Aircraft Accident Report

14

poor-quality information from the CAM (each on separate channels).

29

The airplane was not

equipped with a flight data recorder (FDR).

30

1.12 Wreckage and Impact Information

Examination of the debris path from the runway to the main wreckage site revealed that

the initial wreckage debris on the runway consisted of fragments from the right outboard MLG

tire.

In immediate proximity following the initial tire debris (along the airplane’s direction of

travel), tire skid marks and gouging on the runway surface crossed the runway centerline at an

angle from left to right before generally realigning with the runway heading and continuing

straight off the departure end into a swath of ground scars and debris that extended to the main

wreckage.

The identified debris extended down the runway in the following order (with some

overlap): right outboard MLG tire (some fragments of which were found coated with hydraulic

fluid), airplane landing light, airplane pieces, right inboard MLG tire, left inboard MLG tire, and

left outboard MLG tire. Fragments of the MLG wheel sets were found strewn along the debris

path with few tire fragments attached; all four MLG wheel and brake assemblies showed

grinding and friction damage on the bottom, with the most severe damage evident on the right

outboard wheel. The left and right squat switches were found in the grass at the end of the

runway, separated from their respective MLG struts.

The airplane came to rest on a 25° to 30° embankment on the east side of a five-lane

road. The top and right side of the fuselage were burned away to about the level of the cabin

floor. The aft fuselage forward of the vertical stabilizer was mostly consumed by fire,

particularly beneath the fuselage fuel tank location. Both engines and their mounting structures

were fire damaged. The left engine’s thrust reverser doors were in the stowed position. Remnants

of the thrust reverser door actuating mechanism from the right engine (which sustained more fire

damage than the left) were in locations consistent with the stowed position. Postaccident

examination of the engines revealed that their combustor sections contained organic debris;

thermal damage to the airplane’s engine diagnostic system precluded memory data extraction.

1.13 Medical and Pathological Information

The Lexington County, South Carolina, Office of the Coroner performed autopsy

examinations on the captain, the first officer, and two passengers. The cause of death for both the

captain and the first officer was reported as smoke and fume inhalation and thermal injuries, and

a contributing factor for both was blunt force trauma. The cause of death for the two passengers

was reported as injuries resulting from blunt force trauma. The two survivors received second-

and third-degree burns.

29

The fourth channel did not contain (and was not required to contain) any audio information.

30

According to 14 CFR 135.152(a), the requirement for an FDR does not apply to multiengine,

turbine-powered airplanes configured with fewer than 10 passenger seats, excluding any required crewmember seat.

NTSB Aircraft Accident Report

15

The FAA’s Civil Aerospace Medical Institute performed toxicology testing on samples

from the captain and the first officer. The toxicology reports for the captain and the first officer

indicated that the samples tested negative for ethanol and a wide range of drugs, including major

drugs of abuse (marijuana, cocaine, phencyclidine, amphetamines, and opiates). Twenty percent

carboxyhemoglobin saturation (carbon monoxide), 1.8 (μg/mL) cyanide,

31

and 0.03 (μg/mL,

μg/g) diphenhydramine

32

were detected in the captain’s blood.

33

Diphenhydramine was also

detected in her liver. Twenty-five percent carboxyhemoglobin saturation, 2.07 (μg/mL) cyanide,

and 0.036 (μg/mL, μg/g) diphenhydramine were detected in the first officer’s blood.

Diphenhydramine was also detected in his liver and urine, and ibuprofen

34

was detected in his

urine.

1.14 Fire

According to statements from the passengers and witnesses, a fire erupted in and around

the airplane when it came to rest at final impact. CAE ARFF responders received the alert of the

accident via the crash phone and radio from the airport communication center. All three ARFF

vehicles and all four ARFF personnel on duty arrived at the scene within 5 minutes of

notification and found that the entire length of the airplane and sections of the highway were on

fire. The fire was under control about 10 minutes after the first ARFF crews arrived. Mutual aid

response was provided by Lexington County and the Town of Cayce. Burn lines consistent with

a fuel fire extended downhill from the wing and fuselage fuel tanks, across the road toward the

airport fence, and along the gutter of the road.

1.15 Survival Aspects

The captain was seated in the left cockpit seat, and the first officer was seated in the right

cockpit seat. According to the two surviving passengers, the two fatally injured passengers were

seated in the forward cabin, one in the forward-facing seat on the left and the other on the

side-facing divan on the right. The two survivors were seated in the aft forward-facing seats.

The captain’s seat five-point restraint system buckle was found with four of the five

buckles fastened; the crotch-strap buckle was not located in the wreckage. The first officer’s

five-point restraint system buckle was found with all five buckles fastened. None of the

identified seat belt buckles from the cabin were found fastened (not all buckle components from

the cabin were located).

31

Carbon monoxide and cyanide levels can result from smoke inhalation.

32

Diphenhydramine is an over-the-counter antihistamine with sedative effects that is often used to treat allergy

symptoms (commonly known by the trade name Benadryl®) or as a sleep aid (commonly known by the trade name

Unisom®).

33

The condition and specific anatomical sources of the blood samples from both the captain and the first officer

were not reported.

34

Ibuprofen is an over-the-counter pain reliever and fever reducer commonly known by the trade name

Motrin®.

NTSB Aircraft Accident Report

1.15.1 Survivors’ Descriptions of Crew-Provided Safety Information

The passenger who was seated in the aft forward-facing seat on the right recalled that,

before the airplane taxied, the captain asked the passengers if they knew where the seatbelts were

and told them that the fire extinguisher and the snacks were in the back. The passenger stated

that he did not hear the “usual” safety briefing but noted that the captain told them where the

exits were and stated, “you have all done this before.” He stated that he did not think that the

captain’s briefing sounded very professional. He recalled that he fastened his seatbelt but

indicated that he did not notice what the other passengers did with their seatbelts. He stated that

he assumed that they used them because he was familiar with their travel habits, and they

typically used their seatbelts on every flight.

The other surviving passenger, who was seated in the aft forward-facing seat on the left,

stated that the pilots did not provide a safety briefing and that he did not remember hearing any

specific language about the location of the exits. He recalled that one of the pilots made a

comment that he interpreted to mean that the pilot considered the passengers to be frequent fliers

who were familiar with safety briefings. He stated that he fastened his seatbelt but not very

tightly.

1.15.2 Survivors’ Descriptions of Exiting the Airplane

The passenger in the aft right seat stated that, as soon as the airplane came to a stop, fire

erupted in the cabin. He stated that he remembered being told that there was an exit near him and

that he turned around went to the aft exit door (on the right) and “did what it said to do.” He

stated that he did not remember if there were instructions or arrows on the exit that showed how

to open it but stated that he opened it without difficulty and jumped out onto the wing of the

airplane. He recalled that he went through more fire outside the airplane; ran away from the

airplane; and saw, within 5 seconds, the airplane burst into bigger flames. He stated that, as he

ran, he pulled off his burning clothes.

The passenger in the aft left seat stated that the airplane went up and back down “hard”

and that, before the airplane’s final “very, very hard” impact, he saw something or someone fly

up and hit the ceiling in the forward cabin. He stated that he may have been unconscious for a

few seconds but that he saw the other passenger get up and yell, “we gotta go! We gotta go!” He

indicated that he did not know that there was an exit behind him but that the other passenger

“went right to it,” opened it, and leapt “straight out into a wall of flames.” He stated that he went

to the exit, stayed to the left to try to avoid the fire, and jumped out. He indicated that, when he

landed on the ground, he was on fire and began rolling to put out the fire himself.

16

NTSB Aircraft Accident Report

17

1.15.3 Postaccident Examination of Airplane Exits

The airplane’s main passenger boarding door, a type I exit of a clamshell design with

upper and lower doors,

35

was located at the left forward cabin. The exterior handle and the

interior lower handle were found at the accident site in the closed/locked position, and the door

pins were found in the extended/locked position. The fuselage was deformed at the aft bottom

area of the door frame, and the lower door could not be opened; the upper door latch was

operable with effort.

A type III escape hatch was located in the lavatory area in the rear cabin on the right,

above the lavatory’s seat.

36

The lavatory and escape hatch area were separated from the cabin by

two wooden partitions (extending from floor to ceiling) on each side of the airplane with a

sliding, wooden “pocket” door in the middle that, when open, stowed into the left partition. The

charred remains of this pocket door were found consistent with it having been in the open

(stowed) position; the hatch and the surrounding fuselage were destroyed by fire. The escape

hatch handle and one pin-type latch were found in the debris in the open (unlatched) position.

1.16 Tests and Research

1.16.1 Sound Spectrum Study

The NTSB performed a sound spectrum study to examine a 50-second segment of audio

(from 2354:42 to 2355:32) captured on the CVR by the CAM in the near-final moments on the