Instructions for Use for

Infinite 200 PRO Reader Family

Infinite M Nano

Infinite Lumi

Infinite M Nano+

Infinite M Plex

Infinite F Nano+

Infinite F Plex

Document Part No.: 30125944

2021-06

Document Revision No.: 1.4

2 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 2021-06

WARNING

CAREFULLY READ AND FOLLOW THE INSTRUCTIONS

PROVIDED IN THIS DOCUMENT BEFORE OPERATING THE

INSTRUMENT.

(TRANSLATION FOR GERMAN USERS)

WARNUNG

LESEN UND BEFOLGEN SIE DIE ANWEISUNGEN IN DIESEM

DOKUMENT SORGFÄLTIG, BEVOR SIE DAS GERÄT BEDIENEN.

Notice

Every effort has been made to avoid errors in text and diagrams; however, Tecan

Austria GmbH assumes no responsibility for any errors, which may appear in this

publication.

It is the policy of Tecan Austria GmbH to improve products as new techniques

and components become available. Tecan Austria GmbH therefore reserves the

right to change specifications at any time with appropriate validation, verification,

and approvals.

We would appreciate any comments on this publication.

Manufacturer

Tecan Austria GmbH

Untersbergstr. 1A

A-5082 Grödig, Austria

T +43 62 46 89 33

F +43 62 46 72 770

E-mail: office.austr[email protected]

www.tecan.com

Copyright Information

The contents of this document are the property of Tecan Austria GmbH and are

not to be copied, reproduced or transferred to another person or persons without

prior written permission.

Copyright © Tecan Austria GmbH

All rights reserved.

Printed in Austria

Declaration for EU Certificate

See the last page of these Instructions for Use.

About the Instructions for Use

Original Instructions. This document describes the Infinite 200 PRO Reader

Family multifunctional microplate readers. It is intended as reference and

instructions for use. This document instructs how to:

Install the instrument

Operate the instrument

Clean and maintain the instrument

2021-06 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 3

Remarks on Screenshots

The version number displayed in screenshots may not always be the one of the

currently released version. Screenshots are replaced only if content related to

application has changed.

Trademarks

The following product names and any registered and unregistered trademarks

mentioned in this document are used for identification purposes only and remain

the exclusive property of their respective owners:

• Infinite

®,

i-control

TM

, magellan

TM

, NanoQuant Plate

TM

, Tecan

®

and the Tecan Logo are registered trademarks of

Tecan Group Ltd., Männedorf, Switzerland

• Windows

®

and Excel

®

are registered trademarks of Microsoft Corporation,

Redmond, WA, USA

• ChromaGlo

TM

Dual-Luciferase

®

, Enliten

®

, and NanoBRET

TM

are registered

trademarks of Promega Corporation Madison, WI, USA

• Starna

®

is a registered trademark of Starna Scientific Limited, 52-54 Fowler

Road, Hainault, Essex IG6 3UT England, United Kingdom

• BRET2

TM

, DeepBlueC

®

, and PerkinElmer

®

are registered trademarks of

PerkinElmer, Inc., Waltham, Massachusetts, USA

Warnings, Cautions, and Notes

The following types of notices are used in this publication to highlight important

information or to warn the user of a potentially dangerous situation:

Note

Gives helpful information.

(TRANSLATION FOR GERMAN USERS)

Hinweis

Dieses Zeichen weist auf nützliche Informationen hin.

CAUTION

INDICATES A POSSIBILITY OF INSTRUMENT DAMAGE OR DATA

LOSS IF INSTRUCTIONS ARE NOT FOLLOWED.

(TRANSLATION FOR GERMAN USERS)

VORSICHT

DIES ZEICHEN WEIST AUF DIE MÖGLICHKEIT EINER

GERÄTEBESCHÄDIGUNG ODER EINES DATENVERLUSTES HIN,

WENN DIE ANWEISUNGEN DES HANDBUCHES NICHT

ORDNUNGSGEMÄß BEFOLGT WERDEN.

4 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 2021-06

WARNING

INDICATES THE POSSIBILITY OF SEVERE PERSONAL INJURY,

LOSS OF LIFE OR EQUIPMENT DAMAGE IF THE INSTRUCTIONS

ARE NOT FOLLOWED.

(TRANSLATION FOR GERMAN USERS)

WARNUNG

WENN ANWEISUNGEN, DIE MIT DIESEM ZEICHEN VERSEHEN

SIND, NICHT BEFOLGT WERDEN, BESTEHT DIE GEFAHR VON

SCHWEREN VERLETZUNGEN, VERLUST DES LEBENS ODER

BESCHÄDIGUNG DES GERÄTES.

WARNING

THIS SYMBOL INDICATES THE POSSIBLE PRESENCE OF

BIOLOGICALLY HAZARDOUS MATERIAL. PROPER

LABORATORY SAFETY PRECAUTIONS MUST BE OBSERVED.

(TRANSLATION FOR GERMAN USERS)

WARNUNG

DIESES ZEICHEN WEIST AUF EINE MÖGLICHE GEFAHR DURCH

BIOLOGISCHE WIRKSTOFFE HIN. DIE ENTSPRECHENDEN

LABORSICHERHEITSBESTIMMUNGEN MÜSSEN UNBEDINGT

EINGEHALTEN WERDEN.

WARNING

THIS SYMBOL INDICATES THE POSSIBLE PRESENCE OF

FLAMMABLE MATERIALS AND A RISK OF FIRE. PROPER

LABORATORY SAFETY PRECAUTIONS MUST BE OBSERVED.

(TRANSLATION FOR GERMAN USERS)

WARNUNG

DIESES ZEICHEN WEIST AUF MÖGLICHE ENTFLAMMBARE

MATERIALIEN HIN. DIE ENTSPRECHENDEN

LABORSICHERHEITSBESTIMMUNGEN MÜSSEN UNBEDINGT

EINGEHALTEN WERDEN.

2021-06 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 5

ATTENTION

NEGATIVE ENVIRONMENTAL IMPACTS ASSOCIATED WITH THE

TREATMENT OF WASTE.

• DO NOT TREAT ELECTRICAL AND ELECTRONIC EQUIPMENT

AS UNSORTED MUNICIPAL WASTE.

• COLLECT WASTE ELECTRICAL AND ELECTRONIC

EQUIPMENT SEPARATELY.

(TRANSLATION FOR GERMAN USERS)

ACHTUNG

NEGATIVE UMWELTEINFLÜSSE DURCH ELEKTRO- UND

ELEKTRONIK-ALTGERÄTE

• ENTSORGEN SIE ELEKTRO- UND ELEKTRONIK-ALTGERÄTE

NICHT ALS UNSORTIERTEN SIEDLUNGSABFALL!

• SAMMELN SIE ELEKTRO- UND ELEKTRONIK-ALTGERÄTE

GETRENNT!

FOR CALIFORNIA RESIDENTS ONLY:

WARNING

THIS PRODUCT CAN EXPOSE YOU TO CHEMICALS SUCH AS

LEAD WHICH IS KNOWN TO THE STATE OF CALIFORNIA TO

CAUSE CANCER AND BIRTH DEFECTS OR OTHER

REPRODUCTIVE HARM. FOR MORE INFORMATION GO TO:

WWW.P65WARNINGS.CA.GOV/PRODUCT.

(TRANSLATION FOR GERMAN USERS)

NUR FÜR EINWOHNER KALIFORNIENS:

WARNUNG

DIESES PRODUKT KANN SIE CHEMIKALIEN WIE BLEI

AUSSETZEN, DAS IM STAAT KALIFORNIEN BEKANNT IST,

KREBS UND GEBURTSFEHLER ODER ANDERE REPRODUKTIVE

SCHÄDEN ZU VERURSACHEN. WEITERE INFORMATIONEN

FINDEN SIE UNTER:

WWW.P65WARNINGS.CA.GOV/PRODUCT.

6 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 2021-06

Symbols

Manufacturer

Date of manufacture

CE Conformity Marking

United Kingdom Conformity Assessed

marking shows that the labeled product is following the

applicable regulation in Great Britain.

Consult Instructions for Use

Catalog number

Serial Number

Unique Device Identification

The UDI symbol identifies the data carrier on the label.

USB label

WEEE symbol

China RoHS symbol

TÜV SÜD MARK

2021-06 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 7

Table of Contents

1. Safety ................................................................................................................................................ 11

1.1 Instrument Safety .................................................................................................................... 11

2. General Description ........................................................................................................................ 15

2.1 Instrument ............................................................................................................................... 15

2.1.1 Intended Use ........................................................................................................................... 16

2.1.2 Multifunctionality ..................................................................................................................... 16

2.1.3 Filling Volumes ........................................................................................................................ 17

2.1.4 Performance ........................................................................................................................... 18

2.1.5 User Friendliness .................................................................................................................... 18

2.1.6 Onboard Control Button .......................................................................................................... 18

2.1.7 Rear View ............................................................................................................................... 19

2.2 Software .................................................................................................................................. 20

2.3 Injectors (Optional) .................................................................................................................. 20

2.3.1 Injector Measurement Modes .................................................................................................. 20

2.3.2 Injector Module Diagram ......................................................................................................... 21

2.3.3 Injector Pump Options ............................................................................................................ 21

2.3.4 Storage Bottles and Bottle Holders ......................................................................................... 22

2.3.5 Injector Carrier ........................................................................................................................ 23

2.4 Measurement Techniques ...................................................................................................... 25

2.4.1 Fluorescence .......................................................................................................................... 25

2.4.2 Absorbance ............................................................................................................................. 27

2.4.3 Luminescence ......................................................................................................................... 28

2.5 Optical System ........................................................................................................................ 29

2.5.1 Fluorescence Intensity System (Infinite M configurations) ...................................................... 29

2.5.2 Fluorescence Intensity System (Infinite F configurations) ....................................................... 35

2.5.3 Fluorescence Polarization System (Infinite F Plex only) ......................................................... 38

2.5.4 Absorbance System (Infinite F configurations)........................................................................ 39

2.5.5 Absorbance System (Infinite M configurations) ....................................................................... 41

2.5.6 Luminescence System ............................................................................................................ 44

2.5.7 Cuvette Port (Infinite M Configurations) .................................................................................. 47

3. Installation ....................................................................................................................................... 51

3.1 Unpacking and Inspection ....................................................................................................... 51

3.1.1 Unpacking Procedure ............................................................................................................. 52

3.2 Removal of the Transport Locks ............................................................................................. 54

3.3 Transport and Storage ............................................................................................................ 55

3.3.1 Transport................................................................................................................................. 55

3.3.2 Storage ................................................................................................................................... 55

3.4 Power Requirements .............................................................................................................. 56

3.5 Switching the Instrument On ................................................................................................... 57

4. Operating the Instrument ............................................................................................................... 59

4.1 Introduction ............................................................................................................................. 59

4.2 General Operating Features ................................................................................................... 61

4.2.1 Instrument Start Up ................................................................................................................. 61

4.3 General Options ...................................................................................................................... 61

4.4 Defining Filter Slides (Infinite F configurations) ...................................................................... 63

4.4.1 About Filters ............................................................................................................................ 63

4.4.2 Filter Slide and Filter Orientation ............................................................................................. 63

4.4.3 Installing a Custom Filter......................................................................................................... 65

4.4.4 Defining the Filters .................................................................................................................. 68

4.5 Optimizing Fluorescence Measurements ............................................................................... 72

4.5.1 Instrument Parameters ........................................................................................................... 72

4.5.2 Z-Optimization (FI Top measurements with Infinite M configurations only) ............................. 73

4.5.3 FI Ratio Mode ......................................................................................................................... 78

4.6 FP Measurements ................................................................................................................... 79

4.6.1 Fluorescence Polarization ....................................................................................................... 79

4.6.2 Measurement Blank Range..................................................................................................... 79

8 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 2021-06

4.6.3 G-Factor Settings .................................................................................................................... 80

4.6.4 Measurement with an Uncalibrated G-Factor .......................................................................... 80

4.6.5 Measurement with a Simultaneous G-Factor Calibration......................................................... 81

4.6.6 Measurement with a Calibrated G-Factor ................................................................................ 82

4.6.7 Measurement with a Manual G-Factor..................................................................................... 83

4.6.8 Calculation of Fluorescence Polarization Parameters ............................................................. 84

4.7 Optimizing Absorbance Measurements ................................................................................. 85

4.7.1 Measurement Parameters ....................................................................................................... 85

4.7.2 Absorbance Ratio Mode .......................................................................................................... 85

4.8 Multiple Reads per Well ......................................................................................................... 86

4.8.1 MRW Type ............................................................................................................................... 86

4.8.2 MRW Size ................................................................................................................................ 87

4.8.3 MRW Border ............................................................................................................................ 88

4.8.4 Result Display in MS Excel ...................................................................................................... 89

4.8.5 Miscellaneous Software Features of MRW .............................................................................. 90

4.9 Optimizing Luminescence Measurements ............................................................................. 91

4.9.1 Integration Time ....................................................................................................................... 91

4.9.2 Light Level Attenuation ............................................................................................................ 91

4.10 Measurements with Injectors ................................................................................................. 92

4.10.1 Priming and Washing of the Infinite Reader ............................................................................ 92

4.10.2 Washing ................................................................................................................................... 96

4.10.3 Before Starting a Measurement with Injectors ....................................................................... 102

4.10.4 Injector Modes (i-control) ....................................................................................................... 102

4.11 Blanking Measurements ....................................................................................................... 106

4.12 Cuvette Measurements ........................................................................................................ 107

4.12.1 Cuvette Strip .......................................................................................................................... 107

4.12.2 Cuvette Movements ............................................................................................................... 107

4.12.3 i-control Cuvette Examples .................................................................................................... 108

4.13 i-control Examples ................................................................................................................ 112

4.14 Finishing a Measurement Session ....................................................................................... 117

4.14.1 Disconnecting the Instrument ................................................................................................ 117

4.14.2 Instrument Shut Down ........................................................................................................... 117

5. Instrument Features ..................................................................................................................... 119

5.1 Introduction ........................................................................................................................... 119

5.2 Instrument Specifications ..................................................................................................... 120

5.3 Fluorescence Intensity and Time Resolved Fluorescence (TRF) ........................................ 122

5.3.1 Definition of the Detection Limit ............................................................................................. 122

5.3.2 Fluorescein (Fluorescence Intensity) Top .............................................................................. 122

5.3.3 Fluorescein (Fluorescence Intensity) Bottom ......................................................................... 123

5.3.4 Europium (Time Resolved Fluorescence) .............................................................................. 123

5.4 Fluorescence Polarization (FP) - Infinite F Plex only ........................................................... 124

5.5 Absorbance .......................................................................................................................... 125

5.6 Glow Type Luminescence .................................................................................................... 126

5.6.1 ATP Glow Luminescence ...................................................................................................... 126

5.7 Flash Type Luminescence ................................................................................................... 127

5.8 Dual Color Luminescence (e.g. BRET) ................................................................................ 128

5.9 “On the Fly” Measurements ................................................................................................. 128

5.10 Cuvette Features (Infinite M configurations only) ................................................................ 129

5.10.1 Cuvette Specifications ........................................................................................................... 129

5.11 Injector Specifications .......................................................................................................... 130

5.11.1 Injector Reagent Compatibility ............................................................................................... 130

5.12 Measurement Accessories ................................................................................................... 132

5.12.1 Recommended Filters (Infinite F configurations only) ............................................................ 132

5.12.2 Recommended Types of Microplates .................................................................................... 132

5.12.3 Luminescence Detection ....................................................................................................... 136

6. Quality Control .............................................................................................................................. 139

6.1 Periodic Quality Control Tests .............................................................................................. 139

6.2 Specifications - Passed/Failed Criteria ................................................................................ 140

6.3 Specifications - Test Instructions ......................................................................................... 141

6.3.1 Fluorescence Top .................................................................................................................. 141

2021-06 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 9

6.3.2 Fluorescence Bottom ............................................................................................................ 145

6.3.3 Time Resolved Fluorescence ................................................................................................ 148

6.3.4 Fluorescence Polarization (Infinite F Plex only) .................................................................... 150

6.3.5 Glow Luminescence .............................................................................................................. 151

6.3.6 Absorbance Accuracy ........................................................................................................... 152

6.3.7 Absorbance Wavelength Accuracy ....................................................................................... 152

6.3.8 Absorbance Baseline Flatness (Infinite M configurations) .................................................... 153

6.3.9 Absorbance Baseline Flatness (Infinite F configurations) ..................................................... 154

6.3.10 Absorbance Cuvette (Infinite M configurations only) ............................................................. 155

7. Cleaning and Maintenance ........................................................................................................... 157

7.1 Introduction ........................................................................................................................... 157

7.2 Liquid Spills ........................................................................................................................... 158

7.3 Injector Cleaning and Maintenance ...................................................................................... 159

7.3.1 Daily Maintenance: ............................................................................................................... 159

7.3.2 Weekly/Periodical Maintenance: ........................................................................................... 160

7.4 Instrument Disinfection ......................................................................................................... 161

7.4.1 Disinfection Solutions ............................................................................................................ 161

7.4.2 Disinfection Procedure .......................................................................................................... 162

7.4.3 Safety Certificate ................................................................................................................... 162

7.4.4 Disposal ................................................................................................................................ 163

7.4.5 Disposal of Packing Material ................................................................................................. 163

7.4.6 Disposal of Operating Material .............................................................................................. 164

7.4.7 Disposal of the Instrument .................................................................................................... 164

8. Troubleshooting ............................................................................................................................ 167

Index ......................................................................................................................................................... 171

1. Safety

2021-06 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 11

1. Safety

1.1 Instrument Safety

1. Always follow basic safety precautions when using this product to reduce the

risk of injury, fire, or electrical shock.

2. Read and understand all information in the Instructions for Use. Failure to

read, understand, and follow the instructions in this document may result in

damage to the product, injury to operating personnel or poor instrument

performance.

3. Observe all WARNING and CAUTION statements in this document.

4. Never open the housing of the Infinite 200 PRO while the instrument is

plugged into a power source.

5. Never force a microplate into the instrument.

6. The Infinite 200 PRO is intended as a general purpose laboratory instrument

for professional use. Observe proper laboratory safety precautions, such as

wearing protective clothing and using approved laboratory safety procedures.

CAUTION

TECAN AUSTRIA GMBH HAS TAKEN GREAT CARE IN CREATING THE

STORED PLATE DEFINITION FILES THAT ARE RECEIVED WITH THE

INSTRUMENT SOFTWARE.

WE HAVE TAKEN EVERY PRECAUTION TO ENSURE THAT THE PLATE

HEIGHTS AND WELL DEPTHS ARE CORRECT ACCORDING TO THE DEFINED

PLATE TYPE. THIS PARAMETER IS USED TO DETERMINE THE MINIMUM

DISTANCE BETWEEN THE TOP OF THE PLATE AND THE CEILING OF THE

MEASUREMENT CHAMBER. ADDITIONALLY, TECAN AUSTRIA HAS ADDED A

VERY SMALL SAFETY GAP TO PREVENT ANY DAMAGE OCCURRING TO THE

MEASUREMENT CHAMBER AS A RESULT OF SMALL CHANGES IN PLATE

HEIGHT. THIS DOES NOT AFFECT THE PERFORMANCE OF THE INSTRUMENT.

USERS MUST ENSURE THAT THE PLATE DEFINITION FILE SELECTED

CORRESPONDS TO THE ACTUAL PLATE BEING USED.

USERS SHOULD ALSO TAKE CARE THAT NO POTENTIAL FLUORESCENT OR

LUMINESCENT CONTAMINATION LIES ON TOP OF THE PLATE. BE AWARE

THAT SOME PLATE SEALERS LEAVE BEHIND A STICKY RESIDUE THAT

MUST BE COMPLETELY REMOVED BEFORE STARTING MEASUREMENTS.

1. Safety

12 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 2021-06

(TRANSLATION FOR GERMAN USERS)

VORSICHT

MIT JEDER GERÄTESOFTWARE WIRD AUCH EINE VON TECAN AUSTRIA

GMBH SORGFÄLTIG ERSTELLTE LISTE MIT PLATTENDEFINITIONSDATEIEN

MITGELIEFERT. DIESE DATEIEN ENTHALTEN WICHTIGE

MIKROPLATTENPARAMETER, WIE Z. B. PLATTENHÖHE UND TIEFE DER

KAVITÄT, DIE UNBEDINGT ERFORDERLICH SIND, UM DAS GERÄT

ORDNUNGSGEMÄß ZU BETREIBEN. DIESE PARAMETER DIENEN U. A. DER

BESTIMMUNG DES MINIMALEN ABSTANDES ZWISCHEN

MIKROPLATTENOBERKANNTE UND DER DECKE DER MESSKAMMER. DA DIE

HÖHE VON MIKROPLATTEN CHARGENABHÄNGIGEN VARIATIONEN

UNTERWORFEN SEIN KANN, FÜGT TECAN AUSTRIA NOCH TOLERANZ

HINZU, UM SCHÄDEN AN DER MESSKAMMER ZU VERMEIDEN. DIESER

SICHERHEITSABSTAND HAT KEINEN EINFLUSS AUF DIE LEISTUNG DES

GERÄTES.

DER/DIE BENUTZERIN DES GERÄTES MUSS SICHERSTELLEN, DASS DIE

KORREKTE PLATTENDEFINITIONSDATEI ZUR VERWENDETEN PLATTE FÜR

DIE MESSUNG GELADEN WIRD. SONST KANN DER SICHERHEITSABSTAND

VON DEM GERÄT NICHT RICHTIG BERECHNET WERDEN. DER/DIE

BENUTZERIN MUSS AUCH DARAUF ACHTEN, DASS DIE

MIKROPLATTENOBERFLÄCHE FREI VON FLUORESZIERENDEN UND

LUMINESZIERENDEN KONTAMINATIONEN IST. EINIGE MATERIALIEN FÜR DIE

VERSIEGELUNG VON MIKROPLATTEN KÖNNEN NACH ENTFERNUNG DER

VERSIEGELUNG KLEBRIGE RÜCKSTÄNDE HINTERLASSEN. AUCH DIESE

SOLLTEN UNBEDINGT VOR DER MESSUNG ENTFERNT WERDEN.

CAUTION

BEFORE STARTING MEASUREMENTS, MAKE SURE THAT THE MICROPLATE

POSITION A1 IS INSERTED CORRECTLY. THE POSITION OF WELL A1 HAS TO

BE ON THE UPPER LEFT SIDE.

(TRANSLATION FOR GERMAN USERS)

VORSICHT

PRÜFEN SIE VOR START DER MESSUNG, OB DIE MIKROPLATTE KORREKT

AUF DEN PLATTENTRANSPORT GELEGT WURDE. DIE POSITION A1 MUSS

LINKS OBEN SEIN.

CAUTION

TO INSURE THE OPTIMAL WORKING OF TECAN INSTRUMENTS

WE RECOMMEND A SERVICE INTERVAL OF 6 MONTHS.

(TRANSLATION FOR GERMAN USERS)

VORSICHT

FÜR DIE ERHALTUNG DER OPTIMALEN LEISTUNG DES GERÄTES

EMPFEHLEN WIR EINEN SERVICE-INTERVALL VON 6 MONATEN.

1. Safety

2021-06 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 13

It is assumed that the instrument operators, because of their vocational

experience, are familiar with the necessary safety precautions for handling

chemicals and biohazardous substances.

Adhere to the following laws and guidelines:

1. National industrial protection law

2. Accident prevention regulations

3. Safety data sheets of the reagent manufacturers

WARNING

DEPENDING ON THE APPLICATIONS, PARTS OF INSTRUMENT

MAY COME IN CONTACT WITH BIOHAZARDOUS/INFECTIOUS

MATERIAL. MAKE SURE THAT ONLY QUALIFIED PERSONNEL

OPERATE THE INSTRUMENT. IN CASE OF SERVICE OR WHEN

RELOCATING OR DISPOSING OF THE INSTRUMENT, ALWAYS

DISINFECT THE INSTRUMENT ACCORDING TO THE

INSTRUCTIONS GIVEN IN THIS MANUAL.

(TRANSLATION FOR GERMAN USERS)

WARNUNG

JE NACH APPLIKATION KÖNNEN VERSCHIEDENE TEILE DES

GERÄTES IN KONTAKT MIT INFEKTIÖSEM MATERIAL KOMMEN.

STELLEN SIE SICHER, DASS NUR ENTSPRECHEND

AUSGEBILDETES PERSONAL DAS GERÄT BEDIENT. IM

SERVICEFALL ODER WENN DAS GERÄT IN EIN ANDERES

LABOR/RÄUMLICHKEIT TRANSPORTIERT WIRD ODER IM FALLE

DER ENTSORGUNG MUSS DAS GERÄT ENTSPRECHEND DEN

HANDBUCHANWEISUNGEN VORHER DESINFIZIERT WERDEN.

2. General Description

2021-06 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 15

2. General Description

2.1 Instrument

The Tecan Infinite 200 PRO is a multifunctional microplate reader designed for

the entry-level life science market. The Infinite 200 PRO provides high

performance for the vast majority of today’s microplate applications and research

and is robotic compatible.

Based on the technological concept of the established Infinite reader, six

configurations are available within the Infinite 200 reader family. The six

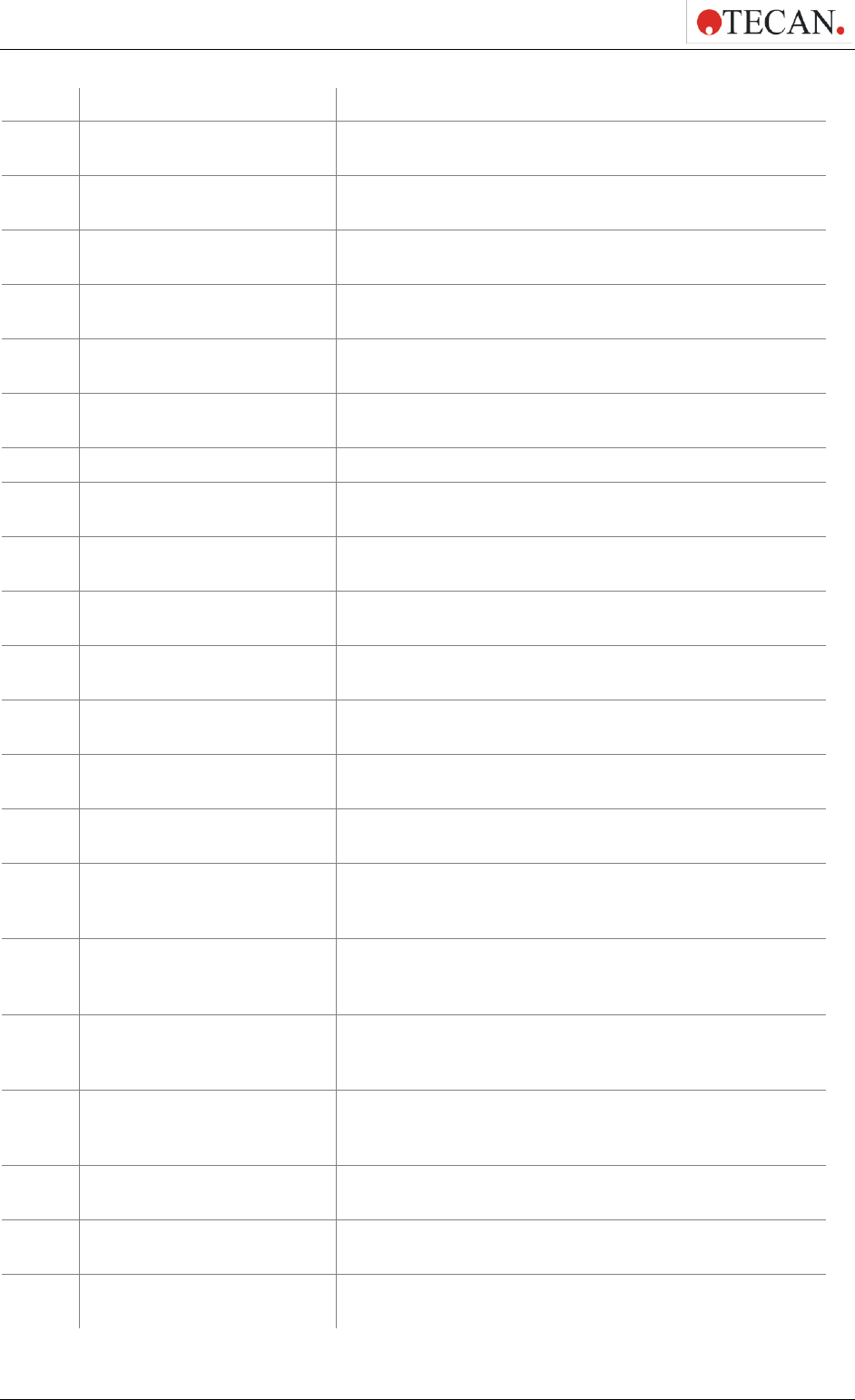

configurations, respective capabilities and options are summarized below:

Monochromator (M)

Configurations

Filter (F)

Configurations

Capabilities

M Nano

M Nano+

Lumi

M Plex

F Nano+

F Plex

Absorbance - monochromator

x

x

x

Absorbance - filter

x

x

Fluorescence - monochromator

x

x

Fluorescence - filter

x

x

Fluoresence - top reading

x

x

x

x

Fluoresence - bottom reading

x

x

x

x

Fluorescence-polarisation - filter

x

Luminescence

x

x

x

Options

1 injector

x

x

x

x

x

x

2 injectors

x

x

x

x

x

x

Cuvette

x

x

x

NanoQuant Plate

x

x

x

x

x

2. General Description

16 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 2021-06

2.1.1 Intended Use

The Infinite 200 PRO has been designed as a general purpose laboratory

instrument for professional use, supporting common 6 to 384-well microplates

conforming to the ANSI/SBS standards (see 5.12.2 Recommended Types of

Microplates for further details).

Note

System Validation by Operating Authority is required. The Infinite 200

PRO has been validated on a selected set of assays only. It is the

responsibility of any operating authority to ensure that the Infinite 200

PRO has been validated for every specific assay used on the

instrument.

(TRANSLATION FOR GERMAN USERS)

Hinweis

System Validierung durch Laborleitung erforderlich. Der Infinite 200

PRO wurde nur für eine Reihe von ausgewählten Assays validiert. Es

liegt daher in der Verantwortung jedes Laborleiters sicherzustellen,

dass der Infinite 200 PRO für jeden spezifischen Assay, der in diesem

Labor auf auf diesem Instrument verwendet wird, auch entsprechend

validiert wurde.

2.1.2 Multifunctionality

The following measurement techniques are supported by the Infinite reader,

depending on the selected configuration of the reader:

• Fluorescence Intensity (FI) Top

• Fluorescence Intensity (FI) Bottom

• Time-Resolved Fluorescence (TRF)

• Fluorescence Resonance Energy Transfer (FRET)

• Flash Fluorescence (with injectors)

• Fluorescence Polarization (FP)

• Absorbance

• Absorbance (with injectors)

• Absorbance in cuvettes

• Glow Luminescence

• Flash Luminescence

• Bioluminescence Resonance Energy Transfer (BRET)

Any common microplate ranging from 6 to 384 well formats conforming to the

ANSI/SBS standards (ANSI/SBS 1-2004; ANSI/SBS 2-2004, ANSI/SBS 3-2004

and ANSI/SBS 4-2004) may be measured with any of the above measurement

techniques. Switching between measurement techniques or plate formats is fully

automated via software. It is not necessary to manually reconfigure the optics in

order to switch between the reading modes supported by the Infinite reader.

2. General Description

2021-06 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 17

2.1.3 Filling Volumes

CAUTION

THE FOLLOWING MICROPLATES CAN BE PROCESSED ONLY WITH THE

SUBSEQUENT FILLING VOLUMES:

• 6-WELL PLATES <= 2000 µL

• 12-WELL PLATES <= 1200 µL

• 24-WELL PLATES <= 1000 µL

• 48-WELL PLATES <= 400 µL

• 96-WELL PLATES <= 200 µL

• 384-WELL PLATES <= 100 µL

LARGER FILLING VOLUMES CAN LEAD TO AN OVERFLOW OF LIQUIDS, WHICH CAN

RESULT IN CROSS-CONTAMINATION. ADDITIONALLY, THE SPILLOVER CAN CAUSE

DAMAGE TO THE DEVICE (E.G. CONTAMINATION OF THE OPTICS AND THE

CENTERING CLAMP).

IF THE WORKING VOLUME IN THE PLATE DEFINITION FILE (PDFX) IS SMALLER THAN

THE ABOVE DEFINED VOLUMES THE SMALLER FILLING VOLUMES MUST BE USED TO

AVOID SPILLING (E.G. CORNING 384-WELL PLATES HAVE A WORKING VOLUME OF

ONLY 80 µL).

FOR FLUIDS THAT HAVE A LOWER VISCOSITY THAN AQUEOUS SOLUTIONS, THE

FILLING VOLUME SHOULD ADDITIONALLY BE OPTIMIZED DURING METHOD

VALIDATION.

(TRANSLATION FOR GERMAN USERS)

VORSICHT

FOLGENDE MIKROPLATTEN KÖNNEN NUR MIT DEN ANGEGEBENEN

FÜLLVOLUMEN VERARBEITET WERDEN:

• 6-WELL PLATTEN <= 2000 µL

• 12-WELL PLATTEN <= 1200 µL

• 24-WELL PLATTEN <= 1000 µL

• 48-WELL PLATTEN <= 400 µL

• 96-WELL PLATTEN <= 200 µL

• 384-WELL PLATTEN <= 100 µL

WERDEN DIESE FÜLLVOLUMEN NICHT BEACHTET, SO KANN ES ZU

ÜBERGREIFENDEN KONTAMINIERUNGEN KOMMEN. DAS ÜBERLAUFEN VON

FLÜSSIGKEITEN KANN ZU SCHÄDEN DES GERÄTS FÜHREN (Z.B. KONTAMINIERUNG

DER OPTIK UND DER ZENTRIERUNGSKLEMME).

IST DAS ARBEITSVOLUMEN IN DER PLATTENDEFINITIONSDATEI (PDFX) KLEINER ALS

DIE OBEN DEFINIERTEN VOLUMEN, SO MUSS DAS KLEINERE FÜLLVOLUMEN

VERWENDET WERDEN, UM EIN ÜBERLAUFEN ZU VERHINDERN (Z.B. HABEN

CORNING 384-WELL PLATTEN EIN ARBEITSVOLUMEN VON NUR 80 µL).

WERDEN FLÜSSIGKEITEN MIT NIEDRIGERER VISKOSITÄT ALS WASSERLÖSUNGEN

VERWENDET, SO SOLLTE DAS FÜLLVOLUMEN ZUSÄTZLICH WÄHREND DER

METHODEN VALIDIERUNG OPTIMIERT WERDEN.

2. General Description

18 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 2021-06

2.1.4 Performance

The Infinite reader has been designed to meet the requirements of a general-

purpose laboratory instrument.

The Infinite reader provides a range of parameters for optimizing the

measurement results according to: the specific configuration, assay type (cell-

based or homogeneous), the microplate type, and the dispensed volumes per

well and dispensing speeds.

2.1.5 User Friendliness

Infinite readers with monochromator configurations offer unparalleled flexibility in

wavelength selection for fluorescence intensity and absorbance measurements.

Via software any wavelength can be easily adjusted within the specified

wavelength range. In addition to single wavelength measurements, absorbance

and fluorescence spectra can be recorded. When running a spectrum there is no

restriction due to cut-off filters.

Infinite readers with filter configurations offer high flexibility for the customization

of fluorescence and absorbance measurements; slides containing fluorescence

and absorbance interference filters are easily accessible to the user.

Note

If the instructions given in this document are not correctly performed,

the instrument will either be damaged or the procedures will not be

performed correctly and the safety of the instrument is not guaranteed.

(TRANSLATION FOR GERMAN USERS)

Hinweis

Werden die Anweisungen des Handbuches nicht korrekt befolgt, kann

das Gerät beschädigt werden bzw. Messprozesse nicht richtig

ausgeführt werden. In diesen Fällen wird für die Sicherheit des Gerätes

keine Garantie übernommen.

2.1.6 Onboard Control Button

The Infinite reader possesses an onboard control button to control plate

movements without the need to be connected to the software. Upon pressing the

‘Plate In/Out’ button, the current position of the plate carrier is automatically

recognized, and the plate is moved into or out of the instrument.

Figure 1: Onboard of the Infinite reader. The ‘Plate In/Out’ button is located in the front

right corner of the top cover.

Plate In/Out button

2. General Description

2021-06 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 19

2.1.7 Rear View

Figure 2: Rear panel

1

Instrument Fan

2

Main Power Switch

3

Main Power Socket

4

Label – China RoHS symbol

5

Label – Technical Inspection Agency (TÜV)

6

Power Supply Fan

7

Name Plate

8

Label – Options/Configuration

9

Injector Connection

10

USB Connection

11

Warranty Label:

ATTENTION

Removing or breaking

THIS seal voids

warranty!

CAUTION

ONLY TECAN AUTHORIZED SERVICE TECHNICIANS ARE ALLOWED TO

OPEN THE INSTRUMENT. REMOVING OR BREAKING THE WARRANTY

SEAL VOIDS THE WARRANTY.

(TRANSLATION FOR GERMAN USERS)

VORSICHT

NUR TECAN AUTORISIERTE SERVICE TECHNIKER DÜRFEN DAS

GERÄT ÖFFNEN. WIRD DAS GARANTIE-SIEGEL VON ANDEREN

PERSONEN ENTFERNT ODER GEBROCHEN, ERLÖSCHEN ALLE

GARANTIEANSPRÜCHE.

2. General Description

20 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 2021-06

2.2 Software

The Infinite reader is delivered with the i-control software, for operating the

instrument and includes an online-help file and a printed Instructions for Use. The

software is formatted as a self-extracting archive on the software storage media.

(For information about the system requirements, refer to the Instructions for Use

for the i-control software. The Instructions for Use for the i-control can be found

on the software storage media.)

For advanced data reduction, the Magellan software can be used to control the

Infinite reader. Magellan offers all functionality for compliance with the FDA

regulation 21 CFR part 11 for electronic records and signatures (for more

information, contact your local Tecan representative).

2.3 Injectors (Optional)

The Infinite reader can be optionally equipped with an injector module consisting

of one or two syringe pumps (XE-1000, Tecan Systems) located in a separate

box, which feed one or two injector needles.

The injector needles are designed to inject liquid in any SBS-conform microplate

well types, in which the well-size is equal to or larger than an SBS standard 384-

well plate.

Figure 3: Injector-box with bottle holders

2.3.1 Injector Measurement Modes

The injectors of the Infinite reader can be used with the following measurement

modes:

• Fluorescence Intensity top and bottom

• Time Resolved Fluorescence

• Absorbance

• Flash Luminescence

• Glow Luminescence

• Dual Color Luminescence

As the measurement position is not the same as the injector position, a short time

delay (approx. < 0.5 s) between injection and reading occurs.

For details on how to set up a measurement with injectors, please refer to chapter

4.10.4 Injector.

2. General Description

2021-06 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 21

2.3.2 Injector Module Diagram

Figure 4: Schematic view of the injector module

2.3.3 Injector Pump Options

There are up to two pumps available for the Infinite reader (see Figure 4 above):

• Pump A feeds injector needle A

• Pump B feeds injector needle B

The Infinite reader can be equipped with one pump (pump A) or two pumps

(pumps A and B):

One Injector Option (one pump): An Infinite reader equipped with one pump

allows injections in any SBS-conform microplate well types, in which the well-size

is equal to or larger than an SBS standard 384-well plate.

• Two Injector Option (two pumps): Some applications, such as flash

luminescence reactions or dual reporter gene assays require the injection of

two independent liquids into the same well; therefore, Tecan Austria offers a

two-injector option.

2. General Description

22 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 2021-06

2.3.4 Storage Bottles and Bottle Holders

The injector box can accommodate up to two 125 ml bottles.

The standard bottle set supplied with the Injector option consists of:

• One 125 ml bottle and one 15 ml bottle for the “One Injector option”

(one pump) or

• One 125 ml bottles and two 15 ml bottles for the “Two Injectors option”

(two pumps).

The injector option includes up to two bottle holders that are designed for tubes of

different sizes and volumes. The bottles and tubes containing the fluids that are

to be injected can be attached securely to the holder using flexible PVC clasps.

The tubes from the injector syringe can be inserted into a carbon needle reaching

down to the bottom of the flask to ensure the optimal aspiration of even small

volumes of fluid.

Figure 5: Bottle holders

2. General Description

2021-06 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 23

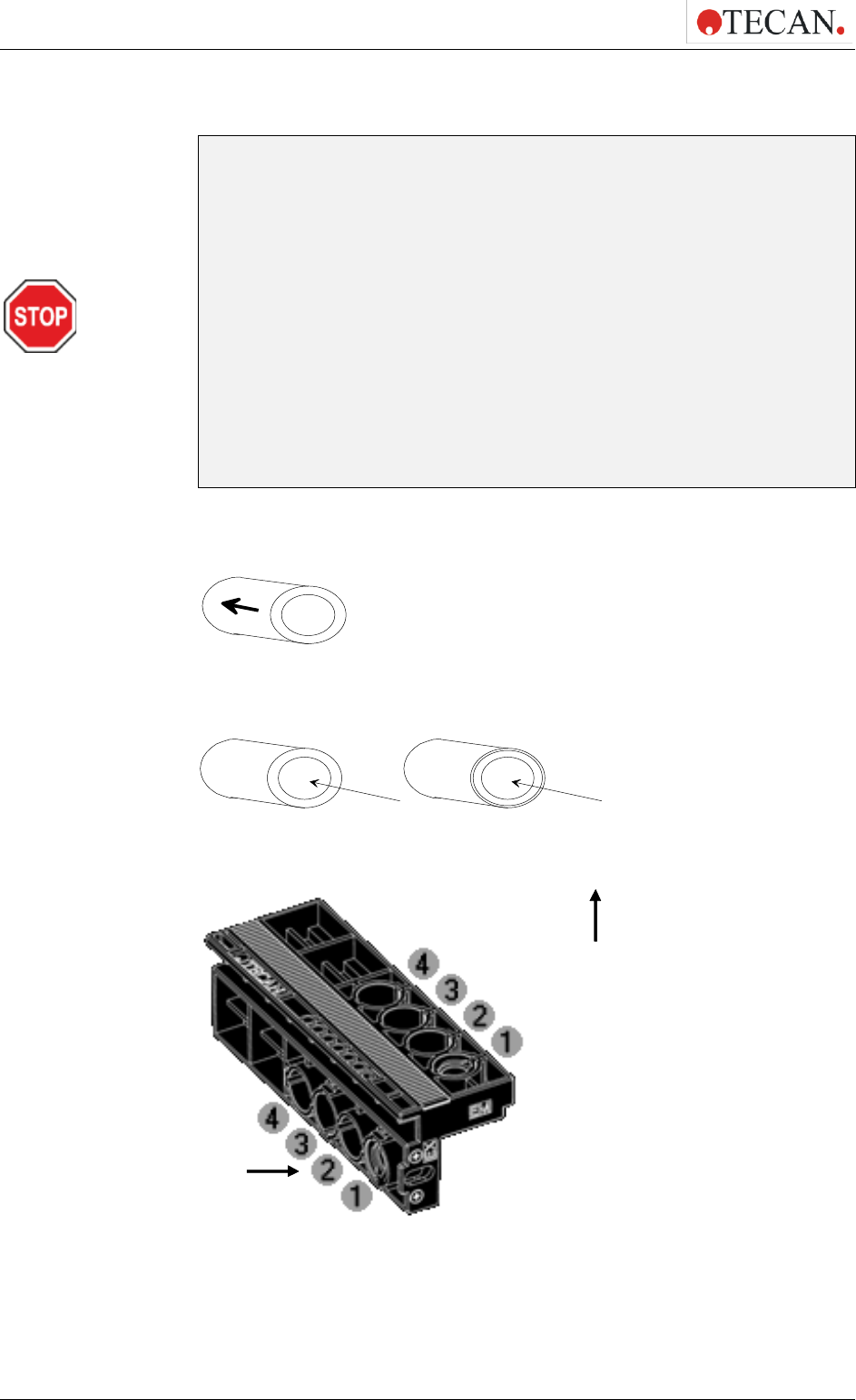

2.3.5 Injector Carrier

The injector carrier, which includes the injector needles, can be easily removed

from the instrument for priming or washing the system and for optimizing the

injection speed.

Figure 6: Injector carrier

When using the injector during a measurement or for just dispensing a plate the

injector carrier must be inserted correctly into the instrument. Remove the injector

dummy and insert the carrier into the injector port. Press the carrier softly into the

injector port until you hear a clicking noise.

The instrument contains an injector sensor that checks that the position of the

injector carrier for the actions ‘inject’ and ‘dispense’ is correct.

If the injector carrier is not inserted correctly, the injector sensor does not

recognize the inserted carrier and neither dispensing nor injection is possible.

On the other hand, actions like washing and priming are enabled although the

injector carrier is inserted; therefore, always make sure that the injector carrier is

in the service position for washing and priming.

Every delivered instrument is equipped with an injector-ready option to be

upgraded with an injector in the field.

CAUTION

THE INJECTOR CARRIER MUST BE IN THE SERVICE POSITION

FOR WASHING UND PRIMING.

PRIME AND WASH MUST NOT BE PERFORMED WHEN THE INJECTOR

IS IN THE INSTRUMENT!

(TRANSLATION FOR GERMAN USERS)

VORSICHT

DIE FUNKTIONEN ‘PRIME’ UND ‘WASH’ DÜRFEN NUR DURCHGEFÜHRT

WERDEN, WENN SICH DER INJEKTOR IN DER SERVICE-POSITION IN

DER INJEKTOR-BOX BEFINDET.

„PRIME“ UND „WASH“ SIND NICHT ERLAUBT, WENN SICH DER

INJEKTOR IM GERÄT BEFINDET.

2. General Description

24 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 2021-06

Figure 7: Inserting the injector carrier into the injector port

CAUTION

IF THE INJECTOR CARRIER IS NOT INSERTED CORRECTLY IN THE

INJECTOR PORT, THE INJECTOR SENSOR WILL NOT DETECT THE

INSERTED INJECTOR AND THEREFORE WASHING AND PRIMING WILL

BE ENABLED, WHICH CAN DAMAGE THE INSTRUMENT.

(TRANSLATION FOR GERMAN USERS)

VORSICHT

WENN DER INJEKTOR NICHT VOLLSTÄNDIG IN DIE INJEKTOR-

EINFÜHRUNG EINRASTET, ARBEITET DER INJEKTOR-SENSOR NICHT

KORREKT. TROTZ EINGEFÜHRTEM INJEKTOR IST DANN „PRIME” UND

„WASH” MÖGLICH, WAS ZU ERHEBLICHEN BESCHÄDIGUNGEN IM

GERÄT FÜHREN KANN.

2. General Description

2021-06 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 25

2.4 Measurement Techniques

The following sections provide an introduction to the Infinite reader measurement

techniques when fully equipped. To keep this compact, a few simplifications have

been made. For details see the references.

2.4.1 Fluorescence

The Infinite reader offers the basic fluorescence measurement technique and

some even more sophisticated variants:

• Fluorescence Intensity (FI) (or simply Fluorescence)

• Fluorescence Resonance Energy Transfer (FRET)

• Fluorescence Time Resolved (TRF)

• Fluorescence Polarization (FP – Infinite F Plex only)

FI may also be used to measure Fluorescence Resonance Energy Transfer

(FRET). For some microplate applications, FRET offers advantages over FI and

TRF, because they simplify assay preparation. These preferably apply for mix

and measure binding studies. Compared to FP, FRET requires both binding

partners to be labeled in a suitable way. On the other hand, FRET may utilize

TRF labels for increased sensitivity, then being referenced as HTRF

(Homogeneous TRF).

TRF should not be confused with Fluorescence Lifetime measurements.

Fluorescent molecules emit light of specific wavelength when struck by light of

shorter wavelength (Stokes Shift). In particular, a single fluorescent molecule can

contribute one fluorescence photon (quantum of light). This is a part of the

energy, which has been absorbed before (electronic excitation), but could not be

released quickly enough into thermal energy.

The average time it takes between excitation and emission is called the

fluorescence lifetime. For many fluorescent molecular species, fluorescence

lifetime is on the order of nanoseconds (prompt fluorescence). After excitation,

fluorescence emission occurs with a certain probability (quantum yield), which

depends on the fluorescent species and its environmental conditions.

For a detailed treatise on fluorescence techniques and applications see:

Principles of Fluorescence Spectroscopy by Joseph R. Lakowicz, Plenum Press.

A) Fluorescence Intensity (FI)

In many microplate applications, the intensity of fluorescence emission is

measured to determine the abundance of fluorescent labeled compounds. In

these assays, other factors having an influence on fluorescence emission need to

be controlled experimentally. Temperature, pH-value, dissolved oxygen, kind of

solvent etc. may significantly affect the fluorescence quantum yield and therefore

the measurement results.

2. General Description

26 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 2021-06

B) Fluorescence Resonance Energy Transfer (FRET)

Some microplate applications utilize a sophisticated dual labeling strategy. The

FRET effect enables you to measure how many of two differently labeled

compounds are in close proximity. This makes it suitable for binding studies.

Basically, FRET is a fluorescence intensity measurement of one of the two

fluorescent labels (acceptor). However, the acceptor is not susceptible to the

excitation wavelength of the light source being used. Instead, the acceptor may

receive excitation energy from the other fluorescent label (donor), if both are

spatially close together. As a prerequisite, the excitation wavelength has to apply

to the donor. Secondly, the emission spectrum of the donor has to overlap the

excitation spectrum of the acceptor (resonance condition). Nevertheless, the

transfer of excitation energy from donor to the acceptor is radiation free.

Some FRET-based applications utilize suitable pairs from the fluorescent protein

family, like GFP/YFP (Green/Yellow Fluorescent Protein, (ref. Using GFP in

FRET-based applications by Brian A. Pollok and Roger Heim – trends in Cell

Biology [Vol.9] February 1999). Overview is given in the Review Article –

Application of Fluorescence Resonance Energy Transfer in the Clinical

Laboratory: Routine and Research by J. Szöllösi, et al. in Cytometry 34, page

159-179 (1998).

Other FRET-based applications take advantage from using TRF labels as the

donor. For example see, High Throughput Screening – Marcel Dekker Inc.

1997, New York, Basel, Hong Kong, section 19 Homogeneous, Time-Resolved

Fluorescence Method for Drug Discovery by Alfred J. Kolb, et al.

C) Time Resolved Fluorescence (TRF)

TRF applies to a class of fluorescent labels (chelates of lanthanides like

Europium, [ref. Europium and Samarium in Time-Resolved

Fluoroimmunoassays by T. Stâhlberg, et. al. - American Laboratory, December

1993 page 15]), some of them having fluorescence lifetimes in excess of 100

microseconds. The Infinite reader uses a Flash lamp light source with flash

duration much shorter than fluorescence lifetime of these species. This offers the

opportunity to measure fluorescence emission at some time, when stray light and

prompt fluorescence have already vanished (Lag Time). Thus, background can

be significantly lowered while sensitivity is improved.

The benefits of TRF consequently apply to assays using multiple labels with

different fluorescence lifetimes.

2. General Description

2021-06 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 27

D) Fluorescence Polarization (FP)

Fluorescence Polarization (FP) measures rotational mobility of a fluorescent

labeled compound. FP is therefore particular suitable for binding studies, because

the tumbling motion of small molecules may be dramatically slowed down after

binding to a larger molecule.

Fluorescence polarization measurements are based on the detection of the

depolarization of fluorescence emission after excitation of a fluorescent molecule

by polarized light. A fluorescent molecule can be visualized as an antenna. Such

a molecule can absorb energy if and only if the polarization of the excitation light

matches the orientation of the antenna. During the fluorescence lifetime, i.e. the

time a molecule remains in the excited state, small molecules diffuse rotationally

relatively rapidly. Hence they re-orient before they emit their photon. As a result

and due to the random character of diffusion, a linearly polarized excitation light

will be translated into a less polarized emission light. Thus, a high resultant mP

value denotes the slow rotation of the labeled molecule, indicating that binding

probably did occur. A resultant low mP value denotes a fast rotation of a

molecule, indicating that binding probably did not occur.

The FP measurement result is calculated from two successive fluorescence

intensity measurements. They differ in the mutual orientation of polarizing filters,

one being placed behind the excitation filter, another ahead of the emission filter.

By processing both data sets, it is possible to measure the extent of how much

the fluorescent label has changed orientation in the time span between excitation

and emission.

2.4.2 Absorbance

Absorbance is a measure for the attenuation of monochromatic light when

transmitted through a sample. Absorbance is defined as:

A = LOG

10

(I

0

/ I

SAMPLE

),

Where I

SAMPLE

is the intensity of the light being transmitted, I

0

the light intensity

not attenuated by sample. The unit is assigned with Optical Density (OD)

Thus, 2.0 OD means 10

2.0

or 100-fold attenuation (1% transmission),

1.0 OD means 10

1.0

or 10-fold attenuation (10% transmission), and

0.1 OD means 10

0.1

or 1.26-fold attenuation (79.4% transmission).

If the sample contains only one species absorbing in that narrow band of

wavelengths, the background corrected absorbance (A) is proportional to the

corresponding concentration of that species (Lambert-Beer's Law).

2. General Description

28 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 2021-06

2.4.3 Luminescence

Glow Type Chemi- or Bioluminescence

The Infinite reader provides measurement of glow type chemi- or

bioluminescence. Glow type means that the luminescence assay glows much

longer than a minute. Luminescence substrates are available, which provide

stable enough light output over hours.

As an example, luminescence can be measured to determine the activity of an

enzyme labeled compound (-peroxidase, -phosphatase). Light emission results

from a luminescence substrate being decomposed by the enzyme. Under excess

of substrate the luminescence signal can be assumed to be proportional to the

abundance of the enzyme labeled compound. As with enzyme-based assays,

control of environmental conditions is rather critical (temperature, pH-value).

For practical aspects of luminescence assays see the following example:

Bioluminescence Methods and Protocols, ed. R.A. LaRossa, Methods in

Molecular Biology 102, Humana Press, 1998

Bioluminescence Resonance Energy Transfer (BRET)

BRET is an advanced, non-destructive, cell-based assay technology that is

perfectly suited for proteomics applications, including receptor research and the

mapping of signal transduction pathways. BRET is based on energy transfer

between fusion proteins containing Renilla luciferase (Rluc) and a mutant of the

Green Fluorescent Protein (GFP). The BRET signal is generated by the oxidation

of p.a. DeepBlueC, a coelenterazine derivative that maximizes spectral resolution

for superior sensitivity. This homogeneous assay technology provides a simple,

robust and versatile platform with applications in basic academic as well as

applied research.

Flash Luminescence

In flash type luminescence assays, the measurement is only done during the

dispensing of the activating reagent or after a short delay time (for Flash

luminescence measurements with the Infinite reader, see also 2.3.1 Injector

Measurement ).

Over the past years luminescence substrates have been improved towards

providing more stable signals. In so-called glow type luminescence assays the

luminescence signal is spread over a wide time scale (e.g. a half-life of 30 min.).

2. General Description

2021-06 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 29

2.5 Optical System

2.5.1 Fluorescence Intensity System (Infinite M configurations)

The optical system of the fluorescence top and bottom system of the Infinite

M configurations is sketched below.

The system consists of:

• Light source system

• Excitation double monochromator

• Fluorescence top optics

• Emission double monochromator

• and fluorescence detection

The solid arrows indicate the light path of the excitation light; the dashed arrows

indicate the emission light path.

To simplify the system, the ‘Flash Monitor’ (see section Flash Monitor, page 32) is

not shown. Each monochromator unit, (2) and (4), is built of two gratings and a

schematic view is displayed in more detail in the figures below.

Fluorescence Intensity Top Diagram

Figure 8: Optical System Fluorescence Top

Adjustable

z-Position

2. General Description

30 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 2021-06

Fluorescence Intensity Bottom Diagram

Figure 9: Optical System Fluorescence Bottom

Figure 10: Detailed view of excitation and emission double monochromator unit

1

2

3

4

5

2. General Description

2021-06 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 31

Fluorescence Intensity Light Source System

Fluorescence applications usually require a specific range of excitation

wavelengths. Additionally, pulsed excitation light may be required (Time Resolved

Fluorescence [TRF]).

The Infinite M configurations light source system is built from the following

components:

• Flash Lamp

• Condensing Optics

• Filter Wheel

• Excitation Double Monochromator

• Fiber Optic Bundle

• Flash lamp Monitor

Flash Lamp

The Infinite M configurations utilizes a high energy Xenon arc discharge lamp

(flash lamp). The flash sparks across a small gap between two electrodes. The

lamp bulb contains a high pressure Xenon atmosphere. The flash decays within a

few microseconds. The flash frequency is 40 Hz.

The Infinite M configurations uses the flash lamp for fluorescence and for

absorbance measurements, although pulsed illumination is a must only for TRF.

The main benefits of this singular kind of lamp are:

High intensity from the deep UV to the near IR

Very long lifetime

Many applications - only one kind of lamp

No warm up time required

Condenser

Condenser type optics from fused silica focus the flash light onto the entrance slit

of the excitation monochromator.

Filter Wheel

A filter wheel is located between the condenser and the excitation

monochromator. The filter wheel contains wavelength specific optical filters,

which are necessary to block undesired diffraction orders produced by the optical

gratings. The filters are set automatically.

Excitation Double Monochromator

In both fluorescence and absorbance applications, the Excitation Double

Monochromator is used to select any desired wavelengths from the flash lamp

spectrum in the range from 230 to 850 nm (spectrally enhanced version) for

fluorescence intensity and from 230 nm to 1000 nm for absorbance applications.

In many cases, fluorescence emission spectra do not depend on the exact

excitation wavelength; therefore, in order to achieve a maximum total

fluorescence signal, a broad excitation bandwidth should be used.

The bandwidth of the Infinite M configurations monochromator system is < 9 nm

for wavelengths > 315 nm and < 5 nm for wavelengths 315 nm.

For a more detailed description of how a monochromator works, see below.

2. General Description

32 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 2021-06

Description of how a Monochromator Works

A monochromator is an optical instrument that enables any wavelength to be

selected from a defined optical spectrum. Its method of operation can be

compared to a tunable optical filter, which allows both the wavelength and

bandwidth to be adjusted.

A monochromator consists of an entrance slit, a dispersive element and an exit

slit. The dispersive element diffracts the light into the optical spectrum and

projects it onto the exit slit. A dispersive element can be realized by using a glass

prism or an optical grating. Modern monochromators such as those used in the

Infinite M configurations are designed with optical gratings.

Rotating the optical grating around its vertical axis moves the spectrum across

the exit slit and only a small part of the spectrum (band pass) passes through the

exit slit. This means that when the monochromator entrance slit is illuminated with

white light, only light with a specific wavelength (monochromatic light) passes

through the exit slit. The wavelength of this light is set by the rotation angle of the

optical grating. The bandwidth is set by the width of the exit slit. The bandwidth is

defined as full width at half maximum (FWHM).

Monochromators block undesired wavelengths, typically amounting to 10

3

. This

means when the monochromator is set for light with a wavelength of 500 nm and

the detector detects a signal of 10,000 counts, light with different wavelengths

creates a signal of only 10 counts. For applications in the fluorescence range, this

blocking is often not sufficient, since the fluorescence light to be detected is

usually much weaker than the excitation light. To achieve a higher level of

blocking, two monochromators are connected in series, i.e. the exit slit of the first

monochromator acts as the entrance slit of the second monochromator

simultaneously. This is known as a double monochromator. In this case, the

blocking count reaches a factor of 10

6

, a value typically achieved by Interference

filters.

In the Infinite M configurations, a double monochromator is installed on both the

excitation and detection side. This opens the opportunity for easy selection of

excitation and fluorescence wavelengths with no limitations by cut off filters.

Fiber Optic Bundle

Light from the exit slit of the Excitation Monochromator is coupled into a fiber

optic bundle, which guides the light either to the top measuring optics or the

bottom measuring optics. The lower end of each fiber bundle acts as a color

specific light source. In both cases, a small portion of the light is always guided to

the flash lamp monitor diode.

Flash Monitor

The light energy of single flashes may fluctuate slightly. To take these variations

into account, a silicon photodiode monitors the energy of every single flash.

Fluorescence and Absorbance measurement results are compensated

correspondingly.

2. General Description

2021-06 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 33

Fluorescence Top/Bottom Optics

Flash light enters the optical system and is focused by the condenser onto the

entrance slit of the Excitation Monochromator. The wavelength of the excitation

light is selected within the monochromator. After passing the monochromator, the

excitation light is coupled into a fiber bundle, which guides the light to the top or

bottom measuring head. The light is then focused into the sample by the

top/bottom lens system.

The fluorescence light is collected by the top/bottom lens system again, coupled

into the fluorescence fiber bundles and guided to the detection system.

The Fluorescence Measuring Optics Top is built from the following components:

• Fluorescence Intensity Lens System Top

• Fluorescence Fiber Bundle

• The bottom optics consists of the following components:

• Fluorescence Bottom Mirror

• Fluorescence Fiber Bundle

Fluorescence Intensity Lens System Top

The exit side of the bundle acts as a color specific light source. The lens system

at the end of the excitation top fiber is designed to focus the excitation light into

the sample, and also collect the fluorescence light and focus it back onto the

fluorescence fiber bundle.

The objective lenses are made from fused silica. This material provides high UV

transmission and is virtually void of auto-fluorescence.

Excitation Spot Size

The size of the fiber bundle cross section determines the diameter of the beam

waist (spot size) in the microplate well. The spot diameter for the M-series is

about 3 mm for the top optics and 2 mm for the bottom optics.

Fluorescence Fiber Bundle Top and Bottom

The fiber bundle plugged into the top/bottom measuring head contains a

homogeneous mixture of both excitation and emission fibers. The emission fibers

guide the fluorescence light to the emission monochromator head where a lens

system focus the light onto the entrance slit of the Emission Monochromator.

Fluorescence Bottom Mirror

The exit side of the bundle acts as a color specific light source. The mirror at the

end of the excitation bottom fiber is designed to focus the excitation light into the

sample and also collects the fluorescence light and focuses it back onto the

fluorescence fiber bundle.

Z-Positioning (Fluorescence Top on Infinite M configurations

only)

The height of the objective above the sample can be adjusted using the Z-

position function. As excitation light is reflected by the sample fluid, z-adjustment

helps to maximize the signal-to-noise ratio. For further details about z-positioning

see chapter 4.5.2 Z-Optimization (FI Top measurements with Infinite M

configurations only).

2. General Description

34 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 2021-06

Fluorescence Intensity Detection

The fluorescence detection system is used for both measuring modes:

fluorescence from above (top) and below the microplate wells (bottom).

The fluorescence light is focused onto the entrance slit of the Emission

Monochromator. After passing the monochromator the light is focused onto the

detector (PMT). A filter wheel is located between the monochromator and the

PMT.

The Fluorescence Detection system is built from the following components:

• Emission Double Monochromator

• Filter Wheel PMT

• PMT Detector

Emission Double Monochromator

Similar to the Excitation Double Monochromator, the Emission Double

Monochromator is used to select any wavelength of the fluorescence signal.

It acts like an adjustable filter to discriminate scatter of excitation light and

nonspecific fluorescence. The wavelength range is selectable from 280 – 850 nm

in the spectrally enhanced instrument. The bandwidth is 20 nm.

Filter Wheel PMT

The filter wheel contains wavelength specific optical filters, which are necessary

to block undesired diffraction orders produced by the optical gratings. The filters

are set automatically.

PMT Detector

A photo-multiplier tube (PMT) is used for the detection of such low light levels

associated with fluorescence. The PMT of the spectrally enhanced version of the

Infinite M configurations is sensitive up to the near infrared (NIR) while still having

low dark current. Electronic circuitry uses analog to digital conversion of PMT

output current. Adjusting the PMT gain enables measurement of a wide range of

concentrations in lower or higher concentration domains. For details, see Section

4.5.1 Instrument Parameters.

2. General Description

2021-06 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 35

2.5.2 Fluorescence Intensity System (Infinite F configurations)

The following parts constitute the fluorescence intensity system of the Infinite F

configurations instrument:

Light Source

Fluorescence Optics

Fluorescence Detection System

The fluorescence top system is shown in Figure 11, the bottom system in Figure

12. The solid arrows indicate the excitation light path; the dashed arrows

determine the emission light path.

Fluorescence Intensity Top Diagram

Figure 11: Fluorescence intensity top system of the Infinite F configurations

2. General Description

36 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 2021-06

Fluorescence Intensity Bottom Diagram

Figure 12: Fluorescence intensity bottom system of the Infinite F configurations

Light Source System

Flash light enters the optical system by being focused through a slit containing

the filter. This opening acts as a color specific light source.

The Infinite F configurations light source system is built from the following

components:

Flash lamp

Condensing Optics

Excitation Filters

Flash lamp Monitor

Flash lamp

The Infinite F configurations utilizes a high energy Xenon arc discharge lamp

(Flash lamp). The flash sparks across a small gap between two electrodes. The

lamp bulb contains a high pressure Xenon atmosphere. The flash decays within

some microseconds.

The flash frequency is 40 Hz.

The Infinite F configurations uses the Flash lamp for fluorescence and for

absorbance measurements, although pulsed illumination is a must only for TRF.

The main benefits of this singular kind of lamp are:

High intensity from the deep UV to the near IR

Very long lifetime

Many applications - only one kind of lamp

No warm up time required

2. General Description

2021-06 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 37

Condenser

Condenser type optics focus the light through the entrance slit to the fluorescence

optical system.

Excitation Filter

Wavelength-specific bandpass filters serve to select the wavelength range of

interest from the whole spectrum of excitation light coming from the flash lamp.

Filters are installed in removable slides and are user-exchangeable.

Flash Monitor

The light energy of single flashes may fluctuate slightly. To take these variations

into account, a reference silicon photodiode monitors the energy of every single

flash. Fluorescence measurement results are compensated correspondingly.

Fluorescence Optics Top

Flash light enters the optical system by being focused through a slit and then

through the excitation filter. Depending on the measured wavelength either a

semi-transparent (50%) or a special dichroic mirror reflects the light towards the

microplate. The objective lens system focuses the light into the sample.

Fluorescence Emission is measured from above the well. Fluorescence light is

collected by the objective, directed through the appropriate mirror, and focused

through the exit slit for detection.

Objective Lens System

The objective is designed to collect the fluorescent light emitted from a well and

focus it through the exit slit to the detection system.

The objective lenses are made from fused silica. This material provides high UV

transmission and is virtually void of auto-fluorescence.

Mirror Selection - Fluorescence Top (Infinite F configurations only)

The Infinite F configurations is equipped with a mirror carrier, which houses a

50% mirror as well as a 510 dichroic mirror.

The advantage of the 50% mirror is that is works with any pair of excitation and

emission wavelengths. However, 50% of excitation light that is directed into the

sample and, subsequently, 50% of the emission light coming out of the sample

are lost.

Dichroic mirrors are wavelength dependent and are designed to reflect a certain

range of wavelengths almost entirely. Dichroic mirrors exhibit a high reflection of

excitation light and a high transmission of emission light and usually give a better

signal-to-noise ratio compared to 50% mirrors.

Available for plate formats up to 384 wells.

Note

A dichroic mirror needs to match the selected fluorescence excitation

and emission wavelengths.

(TRANSLATION FOR GERMAN USERS)

Hinweis

Die gewählten Anregungs- und Emissionswellenlängen müssen mit

dem zulässigen Wellenlängenbereich des dichroischen Spiegels

übereinstimmen.

2. General Description

38 IFU for Infinite 200 PRO No. 30125944 Rev. No. 1.4 2021-06

Mirror Type

Reflection (Excitation)

Transmission (Emission)

50% mirror

230 – 900 nm

230 – 900 nm

510 dichroic (e.g. fluorescein)

320 – 500 nm

520 – 780 nm

According to the wavelengths defined in the measurement script, the dichroic

mirror is selected automatically if both excitation and emission wavelength match

the specified range of that mirror. If either the excitation or the emission

wavelength does not match the ranges of the dichroic mirror, the 50% mirror is

chosen automatically for the measurement.

Fluorescence Optics Bottom

Flash light enters the optical system by being focused through a slit and then

through the excitation filter. The excitation bottom fiber guides the light to the

bottom optics probe, which consists of an elliptical mirror which focuses the light

through the bottom of the microplate into the well. The emitted light is focused

onto the excitation bottom fiber, which guides the light over a mirror through the

emission filter to the fluorescence detection system.

Fluorescence Detection

Emission Filter

Wavelength-specific bandpass filters serve to discriminate unspecific

fluorescence signals from the sample-specific emission light of interest. Filters

are installed in removable slides and are user-exchangeable.

Fluorescence filters may be used interchangeably as excitation or emission

filters, depending on the measurement requirements.

The spot diameter for the Infinite F configurations is about 2 mm.

PMT Detector

A photomultiplier tube (PMT) is used for the detection of such low light levels as

involved with fluorescence. For details, see section Fluorescence Intensity

Detection, page 34.

2.5.3 Fluorescence Polarization System (Infinite F Plex only)

For technical details please refer to chapter 2.5.2 Fluorescence Intensity System

(Infinite F configurations).

The Infinite F Plex, the Infiinite F configuration for Fluorescence Polarization (FP)

measurements, is delivered with a standard FP filter slide. The filter slide is

equipped with filters and polarizers for excitation and emission, at 485 and

535 nm respectively, and can be applied for measuring, for example, fluorescein-

based FP applications.

For details on how to mount polarizers and FP filters please refer to

chapter 4.4 Defining Filter Slides (Infinite F configurations).

2. General Description