®

P R O D U C T I N F O R M A T I O N

PGV Valves

Rugged, Professional-Grade Valves Designed to

Handle the Full Range of Landscape Needs

P

G

V

V

A

L

V

E

S

®

TABLE OF CONTENTS

Product Overview

......................................................................................

1

Features and Benefi ts

.................................................................................

2

Accu-Set

™

Dial Control Pressure Regulation

............................................

6

Accu-Set

™

Installation Instructions

...........................................................

6

Product Comparisons

.................................................................................

7

Technical Information

................................................................................

8

Installation Details

.....................................................................................

9

Valve Operation

.......................................................................................

10

PGV Replacement Parts

...........................................................................

11

1

PGV Valves

The same HUNTER quality found in all of

our remote control valves is also found in the

PGV family. This

P

rofessional

G

rade

V

alve

is a solid, heavy-duty performer designed

to satisfy the requirements of the most

demanding job sites.

Meets the Needs of All Residential/

Commercial Projects

The versatility of the PGV valve is the answer

to anyone who demands options. The valve

is offered as an angle, globe or globe/angle

combination in a full range of sizes, including

1" with or without fl ow control, 1½", and 2".

Flow capability ranges from a low of 0.20 gpm

(0.05 m

3

/hr, 0.76 l/m) all the way up to 120

gpm (27.2 m

3

/hr, 454.2 l/m).

Available as an option, the Hunter

Accu-Set™ valve pressure regulator is an

important tool for the professional installer.

The Accu-Set™ is the product of choice for

installation on PGV valves when the static

supply pressure is just too high for sprinkler

operation or when the irrigation main lines

need to be at maximum pressures due to

long pipe runs. Also, the Accu-Set™ is the

ideal pressure regulator to use when different

irrigation zones require different outlet

pressures due to product specifi cations, such

as sprays and rotors. Easy to install and easy

to read, this dial-in pressure regulating module

automatically adjusts as needed to provide an

accurate and consistent working pressure in

the zone piping.

Designed for Years of Life

Hunter developed the PGV valve with its

multitude of features, because of a market

need for a strong product with dependable

performance.

The rugged, extremely tough body and

bonnet contribute to a high pressure rating

of 150 psi (10.3 bars, 1034 kPa). In addition,

the valve features captive bonnet screws,

diaphragm and a captive solenoid plunger.

Plus, the heavy-duty Hunter solenoid, with

its 5-year warranty, is sure to keep everything

working for years and years.

PRODUCT OVERVIEW

Easy to Install, Easy to Maintain

Maintenance is an ongoing reality to any

project and like all Hunter products, the

easy-maintenance PGV was designed with the

installation and service needs of the profes-

sional installer in mind. Offering a globe/angle

confi guration in one valve allows the installer

to readily place the valve for easy access.

The PGV’s diaphragm, solenoid plunger, and

bonnet screws are all captive parts, eliminating

the chance of lost parts. Through-holes in the

body allow dirt to fall through the screw holes

instead of allowing it to pack at the bottom,

where it can make it impossible to tighten the

screw upon reassembly.

The bonnet screws used in the PGV line

are unique to Hunter valves. These screws,

specifi cally designed for use in plastic,

thread quicker and truer into the valve body.

They are compatible with a variety of tools:

a hex nut driver, a Phillips screwdriver or

slotted screwdriver for easy servicing. When

installing irrigation systems, something as

simple as a bonnet screw design is all that it

takes to save time and money.

P

G

V

V

A

L

V

E

S

®

2

FEATURES AND

BENEFITS

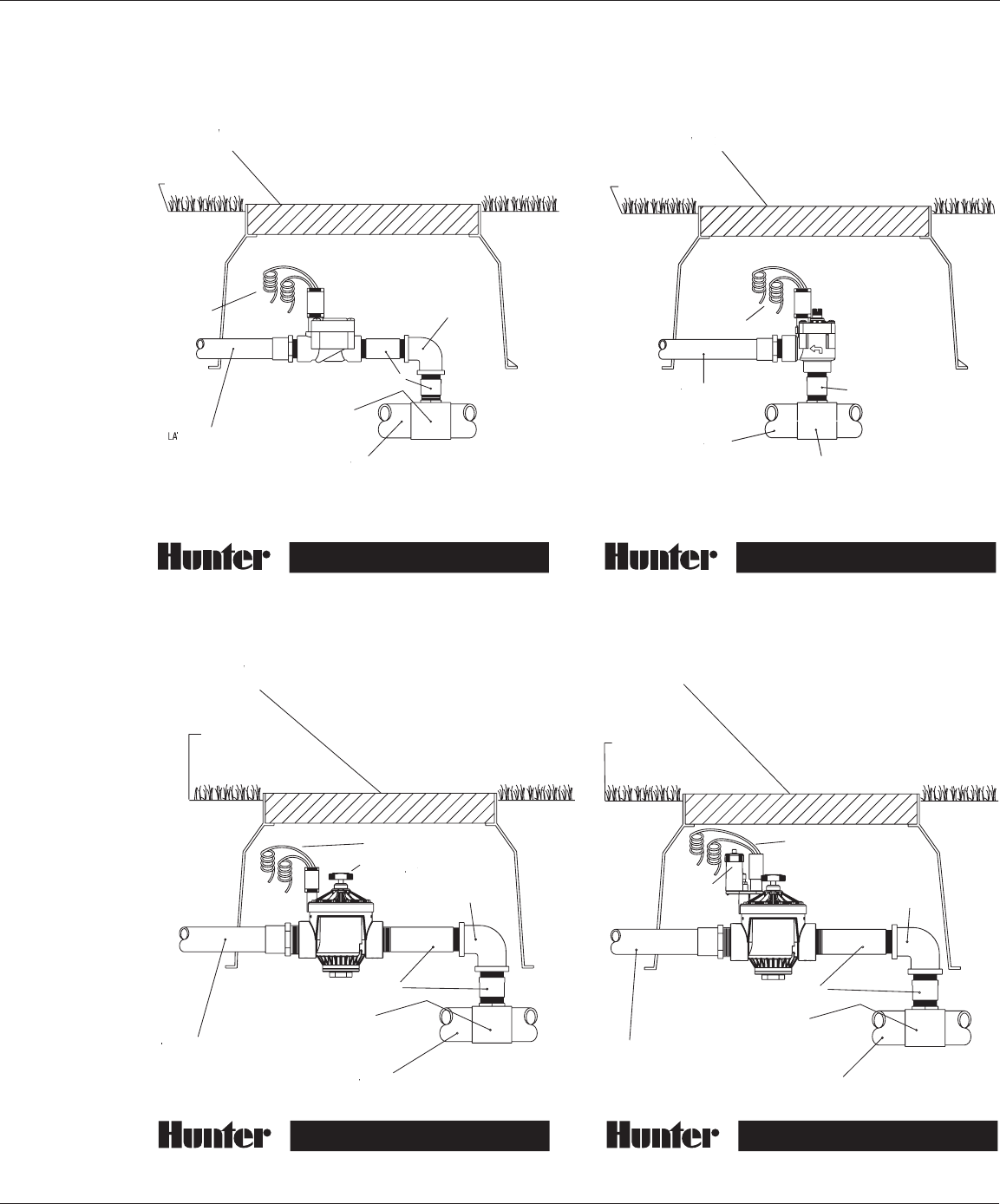

Globe or Angle Models…

Flexibility in design

Many times the irrigation main line is installed

much deeper than the system’s lateral lines.

This may be due to local codes or for freeze

protection. For these situations, Hunter offers

1½" and 2" valves with a globe/angle confi gu-

ration in one valve. The globe confi guration

offers the best choice for those systems that

have the main line at the same depth as the

laterals. The angle confi guration allows the

installer to place the valve on top of a deep

main line, which allows easy access to the

valve for maintenance.

In addition, the PGV angle confi guration

boasts a lower pressure loss across the valve

compared to a globe style valve, providing a

big advantage on systems that may experience

low operating pressures.

Body Options…

Maximum choices, minimum effort

Hunter is aware of the many different valve

requirements that are prevalent in today’s

irrigation market. With that in mind, the PGV

is designed as a very adaptable valve in the

residential/commercial market. The PGV is

available with a variety of inlet and outlet

sizes and confi gurations: NPT, BSP, Male x

Barb, Male x Male, and Slip.

The barb outlet valves have become an

instant hit in the colder regions of the US,

where polyethylene pipe is frequently used

for laterals. Contractors report their installa-

tion times have decreased tremendously when

this valve is used on their jobs. Eliminating

the addition of an extra adapter or two to the

manifold not only saves time and money, but

also saves on the possibility of leaks.

3

PGV Valves

The many options available:

1" GLOBE

with FLOW CONTROL

fpt x fpt — NPT, BSP

mpt x mpt — NPT, BSP

mpt x barb — NPT, BSP

slip x slip

1" GLOBE

without FLOW CONTROL

fpt x fpt — NPT, BSP

mpt x mpt —NPT, BSP

mpt x barb — NPT, BSP

slip x slip

Note: The 1" barb is sized for

USA poly markets only.

1" ANGLE

with FLOW CONTROL

fpt x fpt — NPT

1" ANGLE

without FLOW CONTROL

fpt x fpt — NPT

1½" GLOBE/ANGLE

with FLOW CONTROL

fpt x fpt — NPT, BSP

2" GLOBE/ANGLE

with FLOW CONTROL

fpt x fpt — NPT, BSP

Barbed Connections…

Poly pipe connections made easy

An overwhelming request by Hunter

valve users was to develop a valve

with a barb outlet connection built

into the valve for poly pipe users.

Hunter responded with four 1"

models to choose from. The

1" globe with fl ow control

in MNPT and MBSP threads

and the 1" globe without fl ow control in both

MNPT and MBSP threads are now available.

With all of these models, the time-saving

benefi ts have proven to be substantial for the

installer, because they no longer need to thread

adapters or nipples wrapped with Tefl on tape

into the valve to attach to poly pipe systems.

Flow Range…

Highly versatile valve for all

fl ow requirements

The fl ow range of the PGV is exactly what

installers are looking for in 1", 1½", and

2" valves. Systems requiring a fl ow rate as low

as 0.20 gpm (12 gph), such as for low-volume

irrigation, are easily accommodated with the

1" PGV. Also, irrigation systems running up

to 120 gpm per zone, which can be found on

large commercial sites, are well within the

2" valve’s designed capabilities.

High-Grade Materials Used for a

150 psi Rating…

Made of durable materials to resist wear

If you are in the market for a valve that needs

to take the pressure, the PGV is your choice.

Featuring solid heavy-duty construction built

with an ABS skirted bonnet, this valve takes

up to a constant 150 psi without regard to hot

summer temperatures. The superior design

of the PGV helps eliminate any reduction

in performance when temperatures go up:

a comm on occurrence with 100% PVC

constructed valves.

®

4

Heavy-Duty Solenoid…

Provides dependable operation

and long life

The entire line of Hunter valves has something

in common: the same heavy-duty fi ve-year

warranty solenoid. Hunter's “Totally Encapsu-

lated” solenoid design features a completely

closed bobbin core and glass reinforced

nylon over-molded case. This rugged design

provides increased protection to the solenoid

coil from water intrusion – a primary cause

of failures in solenoids. Installers will fi nd

that not having to stock two or three different

solenoids for valves of the same manufacturer

are a real plus. Another plus is the solenoid’s

captive plunger, which enables easy servicing

of the solenoid but eliminates the chance for

any lost internal parts.

It only takes 1½ turns to remove or replace

the solenoid which makes twisted solenoid

wires a non-issue (a tremendous benefi t to

installers or maintenance people who work

with valves).

The Hunter solenoid is unique because

it operates on a reverse fl ow principle.

The center hole in the solenoid bowl is an

inlet port, instead of an exhaust port. When

installing long wire runs, this solenoid is

very effi cient, especially under high system

pressures.

A big advantage to this reverse fl ow

action is that it reduces potential large

pressure spikes against the valve. Such spikes

could cause damage not only to the valve, but

to other components of the irrigation system

as well. With the PGV, when a surge pressure

spike hits the closed valve, the solenoid

plunger will open slightly to allow the

spike to travel downstream and dissipate

through the zone piping, minimizing any

damage that could occur. The solenoid

plunger then closes immediately, preventing

unscheduled system operation.

Captive Bonnet Screws, Diaphragm

and Solenoid Plunger…

No lost parts during servicing

When servicing is required,

the PGV is the valve that

makes it easy. The screws,

captive within the bonnet,

are designed to be removed

by a nut driver, Phillips, or

slotted screwdriver. Another

unique characteristic to

the PGV line is the type of

screw used. Specifi cally

designed for use in plastic,

the screw sports a large

thread gain, allowing it to

thread quicker and truer into

the valve body.

In addition, all parts are captive within the

solenoid (a great feature in a valve, assuring

those parts will not be lost in the mud). The

PGV also features screw through-holes in the

valve body for trouble-free screw placement.

If dirt gets into these holes it’s no problem:

as the screw is turned into the body, the dirt

comes out the bottom. (It sounds simple, but

other brands actually require removal of the

valve to clean out the debris.)

Fully Supported Diaphragm…

Prevent stress failure in tough conditions

The PGV diaphragm is fully supported by an

ingenious diaphragm support ring designed

to prevent premature stress failure. The ring

is also designed with small holes in it. These

holes allow water to keep the

diaphragm from sticking

to the support ring

after periods of non-

use, such as before

the landscaping is

installed or winter

shutdown.

Diaphragm support ring

prevents stress failures.

Diaphragm support ring

Diaphragm support ring

prevents stress failures.

prevents stress failures.

FEATURES AND BENEFITS

(continued)

5

PGV Valves

Debris Tolerant…

Designed to eliminate failure

caused by debris

With the PGV valve installed in the irrigation

system, callbacks for weeping valves are a

thing of the past. The PGV is highly debris

tolerant because of its “crowned” body seat

and a revolutionary new polymer that is used

in the diaphragm seat assembly.

By virtue of the fact that the

body seat is crowned it

will not allow any con-

taminants to catch

during valve

closing, making

it very diffi cult

for debris to

become trapped

by the diaphragm.

If debris were to

become imbedded in the

diaphragm seat, the polymer material utilized

in the diaphragm seat retains its original shape

after the imbedded debris is fl ushed through

the valve.

Adjustable Flow Control

With Non-rising Handle…

Flow adjustment and servicing made easy

Flow management is a simple process when

using the Hunter PGV with its non-rising fl ow

control handle in the 1½" and 2" sizes. A non-

rising handle means the valve can be placed

closer to the valve box lid for easier

servicing. When fi ne tuning the

system, adjust to the desired

zone fl ow either by hand

or using a valve key. If

necessary, the easy-to-

turn fl ow control handle

completely shuts the

valve off without the

possibility of damage

to the diaphragm,

even under maximum

pressure and fl ow

conditions.

Crowned

body seat

Non-rising

fl ow control

handle

Optional Flow Control in 1" Sizes

Facilitates fl ow management as needed

The 1" PGV can be ordered with or without

an optional fl ow control stem. With the fl ow

control option, zone water pressure and fl ow

can be managed right at the valve for optimum

effi ciency. A removable fl ow control handle,

generously sized for easy gripping, makes fl ow

adjustment a quick and easy process.

Heavy-Duty Bonnet…

Designed to provide maximum durability

Through repeated testing of valve designs, the

PGV has incorporated in it a bonnet that goes

beyond the typical plastic valve bonnet. The

design features a skirt around the perimeter of

the bonnet, which gives it incredible rigidity or

“hoop strength.” An example of this would be

the difference in rigidity between a Styrofoam

cup with a lid attached and one without a

lid attached. Without a lid, the cup is very

malleable, but when a lid is attached the cup

walls are strengthened tremendously.

Bonnet Air Relief…

Air release to minimize system stresses

The PGV is designed with a patent pending

special air relief feature that facilitates the

removal of any air bubble from the top

underside of the bonnet. The removal of air

facilitates the elimination of water hammer.

When the fl ow control stem is pushed

downward, any air trapped in the valve is

released. The water pressure will then force

the stem back up into place without leaking.

Internal Manual Bleed…

Completely dry manual operation

For fast manual operation, a quick ½ turn of

the solenoid allows water to bleed off of the

top of the diaphragm and, as a result, opens the

valve. All the water goes through the valve,

which means no more water continuously

leaking into valve boxes.

®

6

Accu-Set™ Dial Control

Pressure Regulation…

For use on 1½" and 2" valves

Exact pressure settings are a certainty every

time with Hunter

,

s Accu-Set™ pressure

regulating module with its easy-to-read dial

settings. This dial assures exact downstream

pressure between 20 and 100 psi (1.4 to

7.0 bars, 138 to 689 kPa). There are no extra

gauges to carry for pressure adjustments or

inspection. (A schraeder valve is included

on the unit for job specifi cations requiring

checking and setting using a gauge only.)

The Accu-Set dial-in module provides an

accurate working (or dynamic) pressure to

the zone. The module constantly adjusts as

needed to provide a consistent outlet pressure

regardless of inlet pressure variations.

The Accu-Set pressure regulator is an

important tool a professional installer will

use when the irrigation main lines need to

be at maximum pressures due to long pipe

runs or when static supply pressures are

too high for sprinkler operation. Also, the

Accu-Set is the product of choice when

different zones require different outlet

pressures due to product specifi cations, such as

large rotor sprinklers zoned off the same main

line as sprayheads.

The benefi t of the Accu-Set is that the

irrigation system does not need to be

pressurized to adjust it, resulting in a very

fast installation. With this unique pressure

regulating module, just set the easy-to-read

dial to the desired pressure, with or without the

system operating. The pressure dialed in is the

pressure delivered to the zone.

The optional Accu-Set pressure regulating

module is easy to retrofi t on 1½" and 2" fi eld

installed PGV valves. On systems determined

to have high-pressure problems after installa-

tion, the amount of time saved in labor, along

with reduced costs, is considerable. That’s

because the Accu-Set is installed without

a hassle, without cutting pipe and without

replacing valves.

Accu-Set Installation Instructions

1. Remove the solenoid from the Hunter

PGV irrigation valve. (The 1" valve with

fl ow control is not designed for use with

the Accu-Set.)

2. Thread the Accu-Set into the solenoid area

of the PGV.

3. Thread the solenoid into the Accu-Set.

Accu-Set Pressure

Regulator Adjustment

1. Turn the clear dial on the top of the

Accu-Set until the arrow underneath

the clear dial is pointing to the desired

downstream pressure.

2. The white colored scale is for PSI, the

yellow colored scale is for BAR.

FEATURES AND BENEFITS

(continued)

7

PGV Valves

Features

Hunter

PGV

Rainbird

PGA

Irritrol

200B

Toro

252

Nelson

7900

Weathermatic

21000

150 PSI Rated Operating Pressure

✔

✔

✔

✔

✔

✔

Models to Accommodate

Globe/Angle Confi guration

✔

✔

✔

✔

✔

Flow Control with Non-Rising Handle

✔

✔

✔

Internal Manual Bleed

✔

✔

✔

✔

✔

Bonnet Air Relief

✔

✔

✔

✔

Captive Diaphragm

✔

1" model

Captive Bonnet Screws

✔

✔

1" model

Triple Tool Stainless Steel Bonnet Screws

✔

✔

1" model

Easy Bonnet Removal (4 Screws on 1" Valve)

✔

✔

Less Than 1½ Turns to Remove Solenoid

✔

Reverse-Flow Solenoid Design to

Reduce Line Surges

✔

Interchangeable Solenoid with All Hunter

Plastic Valves

✔

✔

✔

Female Inlet/Outlet – NPT / BSP Option

✔

✔

✔

✔

✔

✔

Male Inlet/Outlet – MPT / Barb Option

✔

1" Valve Inlet/Outlet – Solvent-Weld

Slip Option

✔

Vent Holes in Diaphragm Support

✔

Dial to Setting Pressure Regulator

Option without extraneous tubing

✔

✔

Less Than 2.5 PSI Loss at 25 GPM in 1" Valve

✔

Less Than 3.1 PSI Loss at 100 GPM

in 2" Valve

✔

✔

Optional Conduit Cover

✔

✔

✔

✔

PRODUCT COMPARISONS

S P E C I F I C A T I O N G U I D E

EXAMPLE:

PGV - 100G - S - AS

MODEL

PGV

FEATURES

100G

= 1" Globe Valve, no Flow Control

101G

= 1" Globe Valve, with Flow Control

100A

= 1" Angle Valve, no Flow Control

101A

= 1" Angle Valve, with Flow Control

100MB

= 1" Globe Valve, no Flow Control,

Male Thread x Barb

100MM

= 1" Globe Valve, no Flow Control,

Male x Male

101MM

= 1" Globe Valve, with Flow Control,

Male x Male

151

= 1½" Globe/Angle Valve, with Flow Control

201

= 2" Globe/Angle Valve, with Flow Control

OPTIONS FACTORY INSTALLED

S

= Slip x Slip (1" Models Only)

B

= BSP Threads

DC

= DC Latching Solenoid

OPTIONS USER INSTALLED

AS

= Accu-Set™ Pressure Regulator

(1½" and 2" Models Only)

R

= Reclaimed Water Identifi cation

Handle or Tag

CC

= Conduit Cover

®

8

TECHNICAL INFORMATION

Models

PGV-100G – 1" plastic globe valve

PGV-101G – 1" plastic globe valve with

fl ow control

PGV-100A – 1" plastic angle valve

PGV-101A – 1" plastic angle valve with

fl ow control

PGV-100MM – 1" plastic globe valve,

male x male threads

PGV-101MM – 1" plastic globe valve with

fl ow control, male x male threads

PGV-100MB – 1" plastic globe valve,

male thread x barb

PGV-101MB – 1" plastic globe valve with

fl ow control, male thread x barb

PGV-151 – 11/2" plastic globe/angle valve

with fl ow control

PGV-201 – 2" plastic globe/angle valve with

fl ow control

Dimensions

• 1" Globe – 5" H (13 cm) x

4½" L (11 cm) x 2 1/2" W (6 cm)

• 1" Angle – 5 1/2" H (14 cm) x

3½" L (9 cm) x 2 3/4" W (7 cm)

• 1½" Globe/Angle – 7½" H (19.1 cm) x

5 ¾" L (14.6 cm) x 4½" W (10.8 cm)

• 2" Globe/Angle – 8" H (20.3 cm) x

6¾" L (17.1 cm) x 5¼" W (13.3 cm)

Operating Specifi cations

• Flow: 0.20 to 120 gpm

(0.05 to 27.2 m

3

/hr; 0.76 to 454.2 l/min)

• Pressure: 20 to 150 psi

(1.4 to 10.3 bars; 138 to 1034 kPa)

• Heavy-duty solenoid: 24VAC,

370mA inrush curent, 190mA holding

current, 60 cycles

• 475mA inrush current, 230mA holding

current, 50 cycles

OPTIONS Available

• Accu-Set™ pressure regulator

• Reclaimed water identifi cation handle

• DC latching solenoid

• Conduit cover

PGV Pressure Loss in PSI

GPM

1" Globe

1" Angle

1½" Globe

1½" Angle

2" Globe

2" Angle

1

1.1

1.0

5

1.9

1.0

10

1.9

1.0

15

1.6

1.0

20

3.3

2.0

3.0

3.0

1.0

1.0

30

6.1

3.0

3.0

3.0

1.0

2.0

40

3.0

3.0

2.0

2.0

50

4.0

3.5

1.0

1.0

60

5.0

4.0

2.0

2.0

80

5.5

4.5

3.0

2.0

100

5.0

3.0

120

6.0

5.0

PGV Pressure Loss in Bars

m

3

/hr

1" Globe

1" Angle

1½" Globe

1½" Angle

2" Globe

2" Angle

0.23

0.08

0.07

1.14

0.13

0.07

2.27

0.13

0.07

3.41

0.11

0.07

4.54

0.23

0.14

0.21

0.21

0.07

6.81

0.42

0.21

0.21

0.21

0.07

9.08

0.21

0.21

0.14

11.36

0.28

0.24

0.07

13.63

0.34

0.28

0.14

18.17

0.38

0.31

0.14

22.71

0.21

27.25

0.34

SRV Pressure Loss

in kPa

l/min

1" Globe

1" Angle

4

7.58

6.89

19

13.10

6.89

38

13.10

6.89

52

11.03

6.89

76

22.75

13.79

114

42.06

20.68

9

PGV Valves

INSTALLATION DETAILS

2"PGVW/PR2" PGV-NP

1” PGV-ANGLE

®

LA

TERAL LINE

LA

LA

PLASTIC

VA

L

VE BO

LL

X

VE BO

VE BO

T

O SPRINKLERS

CONTR

OL

WIRE

SCHEDULE 80 PVC NIPPLE

MAIN LINE FITTING

MAIN SUPPL

Y LINE

MAIN SUPPL

MAIN SUPPL

FINISH GRADE

WITH CO

VER

1” PGV-GLOBE

®

TERAL LINE

LA

LA

PLASTIC

VA

L

VE BO

LL

X

VE BO

VE BO

T

O SPRINKLERS

CONTR

OL

WIRE

SCHEDULE 80

PVC NIPPLE

MAIN LINE FITTING

MAIN SUPPL

Y LINE

MAIN SUPPL

MAIN SUPPL

FINISH

GRADE

WITH CO

VER

90

°

ELL-PVC

® ®

LA

TERAL LINE

LA

LA

PLASTIC

VA

L

VE BO

LL

X

T

O SPRINKLERS

SCHEDULE 80 PVC NIPPLE

MAIN LINE FITTING

MAIN SUPPL

Y LINE

MAIN SUPPL

MAIN SUPPL

FINISH GRADE

WITH CO

VER

90

°

ELL-PVC

CONTR

OL

WIRE

LATERAL LINE

PLASTIC VALVE BOX

TO SPRINKLERS

SCHEDULE 80 PVC NIPPLE

MAIN LINE FITTING

MAIN SUPPLY LINE

FINISH GRADE

WITH COVER

90° ELL-PVC

CONTROL WIRE

PRESSURE

REGULATOR

RECLAIMED W

A

RECLAIMED W

RECLAIMED W

TER

A

A

IDENTIFICA

TION HANDLE

IDENTIFICA

IDENTIFICA

®

10

VALVE OPERATION

Basic Principles of Valve Operation

Water enters the valve from the system main

line and exerts a force against the center of

the valve’s diaphragm. A small orifi ce in the

diaphragm allows the water to fl ow through

to the upper chamber between the diaphragm

and the bonnet. The water continues to travel

on through a port in the bonnet to the solenoid

area. The solenoid has a light spring loaded

metal piston that, when the valve is closed,

covers the inlet port hole. The surface area

that the water comes in contact with on top

of the diaphragm is greater than the surface

area on the bottom of the diaphragm, so the

valve stays closed until the water in the upper

chamber is released. (pressure x area = force)

Electrically Opening a Valve

When the solenoid coil is electrically charged,

the current creates an electromagnetic fi eld

and pulls the piston off of the port hole seat

allowing water to fl ow into the solenoid

chamber, out of the solenoid exhaust port, and

into the downstream pipe. The solenoid ports

are larger than the orifi ce in the diaphragm,

so the water fl ows out of the upper diaphragm/

bonnet chamber faster than it is allowed

to enter. The pressure on the top of the

diaphragm is released through these ports, and

the force from the mainline side pushes against

the diaphragm and causes the valve to open.

Manually Opening a Valve

The same principle is at work when a valve

is manually opened using the manual bleed.

The pressure on the top of the diaphragm

is released through the use of an internal or

external bleed. The internal bleed on the PGV

mechanically lifts the solenoid piston off of

the upper chamber exhaust port allowing the

water to be released into the downstream pipe.

Some valves have an external bleed which

allows water to exit the upper diaphragm

chamber into the valve box.

Closing a Valve

When the controller turns off the low voltage

current fl ow, the solenoid piston spring pushes

the piston back over the inlet port, and stops

the fl ow of water from going through the

solenoid chamber and exhaust port. The upper

diaphragm/bonnet chamber begins to fi ll, and

soon reaches an equilibrium point when the psi

(pounds per square inch) is the same on both

sides of the diaphragm. The diaphragm spring

continues to gently push on the diaphragm,

closing the valve further. The combination of

the spring exerting pressure on the diaphragm

and the water building up in the upper

chamber bring the valve to a closed position.

11

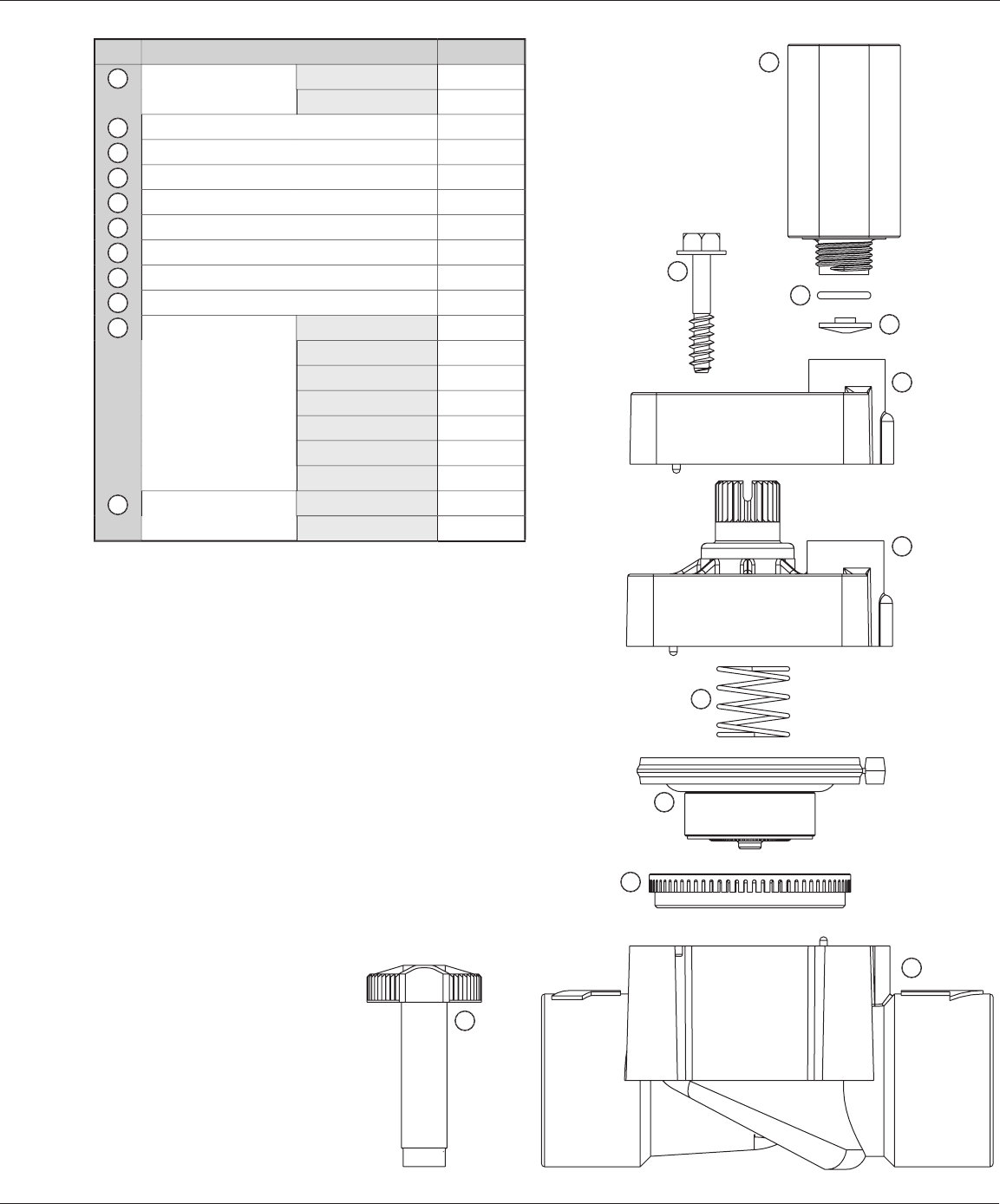

PGV-100G/101G: PLASTIC VALVES

1

2

3

4

5

6

7

8

9

10

10

10

11

11

11

Item

Description

Catalog No.

Solenoid Assembly

(Includes Parts 2 & 3)

AC Solenoid

434100

DC Solenoid

458200

O-Ring

262600

Solenoid Seal

364400

Bonnet Screw

427300

Bonnet without Flow Control

458000

Bonnet with Flow Control

435005

Diaphragm Spring

266000

Diaphragm Assembly

332100

Diaphragm Support Ring

331300

Body

Female, NPT Thread

457700

Female, BSP Thread

457705

Female, Slip x Slip

457710

Male x Male, NPT

433400

Male x Male, BSP

433405

Male x Barb, NPT

460700

Male x Barb, BSP

460705

Flow Control Handle

Black

269200

Purple

269205

10

10

10

6

7

8

9

11

11

11

1

2

3

4

5

12

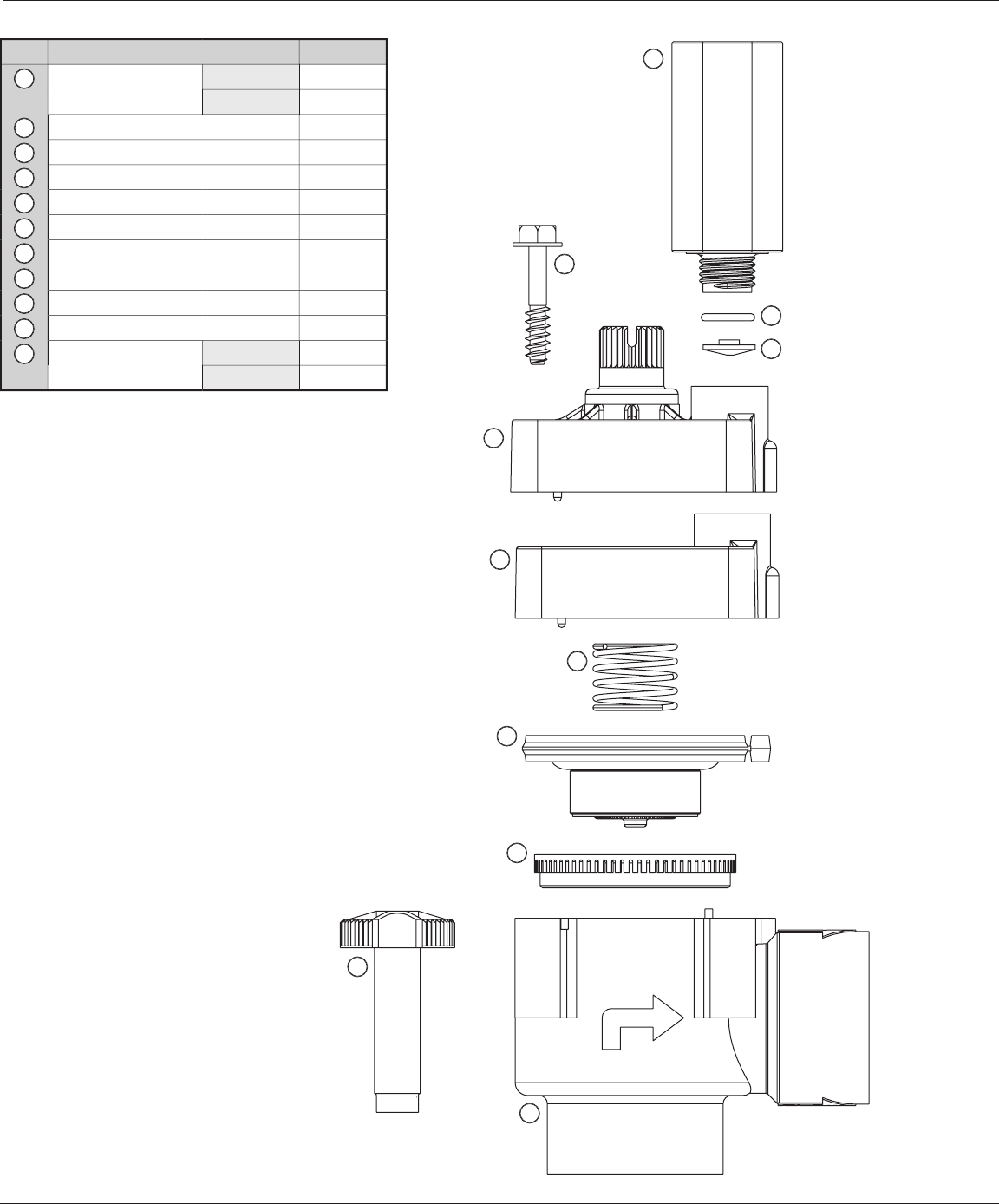

PGV-100A/101A: PLASTIC VALVES

Item

Description

Catalog No.

Solenoid Assembly

(Includes Parts 2 & 3)

AC Solenoid

434100

DC Solenoid

458200

O-Ring

262600

Solenoid Seal

364400

Bonnet Screw

427300

Bonnet with Flow Control

379405

Bonnet without Flow Control

435005

Diaphragm Spring

266000

Diaphragm Assembly

332100

Diaphragm Support Ring

331300

Body

407000

Flow Control Handle

Black

269200

Purple

269205

10

10

10

6

7

8

9

11

11

11

1

2

3

4

5

1

2

3

4

5

6

7

8

9

10

10

10

11

11

11

13

Item

Description

Catalog No.

Solenoid Assembly

(Includes Parts 2 & 3)

AC Solenoid

434100

DC Solenoid

458200

O-Ring

262600

Solenoid Seal

364400

Flow Control Handle Screw

334000

Flow Control Handle

Black

412700

Purple

412705

Bonnet Screw

472800

Bonnet

1½"

414000

2"

415500

Flow Control Stem

(Includes

O-Ring, Stem, Nut and Rod)

1½"

421500

2"

414600

Spring

1½"

412300

2"

414200

Diaphragm Assembly

1½"

414100

2"

415600

Diaphragm Support

1½"

413100

2"

414800

Body

1½" NPT

433200

1½" BSP

433205

2" NPT

433300

2" BSP

433305

Body Plug without O-Ring

1½" NPT

419200

1½" BSP

419205

2" NPT

419300

2" BSP

419305

Plug O-Ring

1½"

413900

2"

415400

10

10

10

6

7

8

9

11

11

11

12

12

12

13

13

13

14

14

14

1

2

3

4

5

PGV-151G, 201G: PLASTIC VALVES

1

2

3

4

5

6

8

9

10

10

10

11

11

11

12

12

12

14

14

14

14

ACCU-SET™

Item

Description

Catalog No.

Adjustment Knob

368500

O-Ring

262600

Inlet Seal

368200

1

2

3

1

2

3

®

Hunter Industries Incorporated • The Irrigation Innovators

© 2003 Hunter Industries Incorporated

1940 Diamond Street • San Marcos, California 92069 • TEL: (1) 760-744-5240 • FAX: (1) 760-744-7461

www.HunterIndustries.com

P/N 700651 LIT-294 1/03