Laser PFIB for large-volume 3D EBSD:

a correlative microscopy perspective

Application note

Authors

Bartłomiej Winiarski, Ph.D.,

Thermo Fisher Scientific.

The Thermo Scientific

™

Helios

™

Laser Hydra System

features our most recent advances in multi-beam

instrumentation, combining a femtosecond laser with a

rapidly switchable multi-ion species plasma focused ion

beam (PFIB) and a field-emission gun scanning electron

microscope (FEG-SEM). This combination expands the

boundaries of traditional Thermo Scientific

™

DualBeam

™

Technology to deliver high-quality macroscale cross-

sections for rapid, large-volume analysis of challenging

materials at nanometer resolution.

Introduction

The advent of commercial FIB-SEM in

the 2000s enabled automated serial-

sectioning tomography, 3D-energy-

dispersive spectroscopy (3D-EDS), and

3D electron-backscatter diffraction

(3D-EBSD) of material volumes smaller

than 40×40×40 µm³. Since 2015, Xe⁺

plasma FIB-SEM (PFIB-SEM) has

expanded these techniques to volumes

of ~250×250×250 µm³, with voxels

approximately dozens of nanometers

in size. Since 2019, the addition of

femto-second laser ablation to Xe⁺ PFIB-SEM pushed these 3D techniques further to

millimeter-scale volumes,

1-3

raising the standard for multi-modal data collection from

nanometers to millimeters. In 2021, fast-switching multi-ion PFIB (Xe⁺, O⁺, Ar⁺, or N⁺)

further extended the applications of laser PFIB.

Figure 1. 3D volume of an aluminum alloy

obtained with laser serial sectioning.² Images

were rendered in Dream 3D, freeware software

for 3D EBSD post-processing and visualization.

640 μm

570 μm

660 μm

C

D

B

PFIB

Adapter

SEM

Laser

CT

post

Sample

holder

These “DualBeam” and “TriBeam” platforms fit seamlessly

in multi-scale and multi-modal correlative microscopy (CM)

methodologies. CM workflows coordinate the characterization

of materials across a range of length scales to solve scientific

problems in 2D and 3D, including time-resolved experiments.

Correlative microscopy in materials and life sciences can

use a number of potential 3D methods such as micro/nano

X-ray computed tomography, optical microscopy, (P)FIB-

SEM, transmission electron microscopy (TEM), as well as

nano-computed tomography in TEM and SEM.

4,5

Combining

these methods for the same region of interest at different length

scales allows 2D/3D spatial and temporal registration of many

imaging modalities, i.e., visible light, cathodoluminescence,

and electron imaging, ion microscopy, EBSD, WDS and EDS

analytics, X-ray tomography, magnetic resonance imaging,

Raman, atomic force microscopy, etc.

Figure 2 demonstrates various 3D data collection techniques

used in material science and the length scales they can

access.⁶ Figure 3 shows the serial sectioning techniques used

for 3D EBSD.¹

This application note discusses current developments in 3D

EBSD for correlative microscopy, using the laser multi-ion PFIB-

SEM. A study from The University of Manchester is highlighted

as a practical example, where the CM workflow is applied to

the large-volume analysis of environmentally assisted cracks in

7xxx alloys.²

Methods

3D correlative microscopy/tomography workflow

The basic workflow (Figure 4a) uses the Helios Laser Hydra

System together with a micro X-ray computed tomography

(X-ray µCT) scanner, a cross-platform holder/adapter kit

(Figure 4b), and Thermo Scientific

™

Avizo

™

3D Software. The

workflow can be extended to 3D nanoscale investigations using

TEM and/or atom probe tomography (APT) (Figure 2).

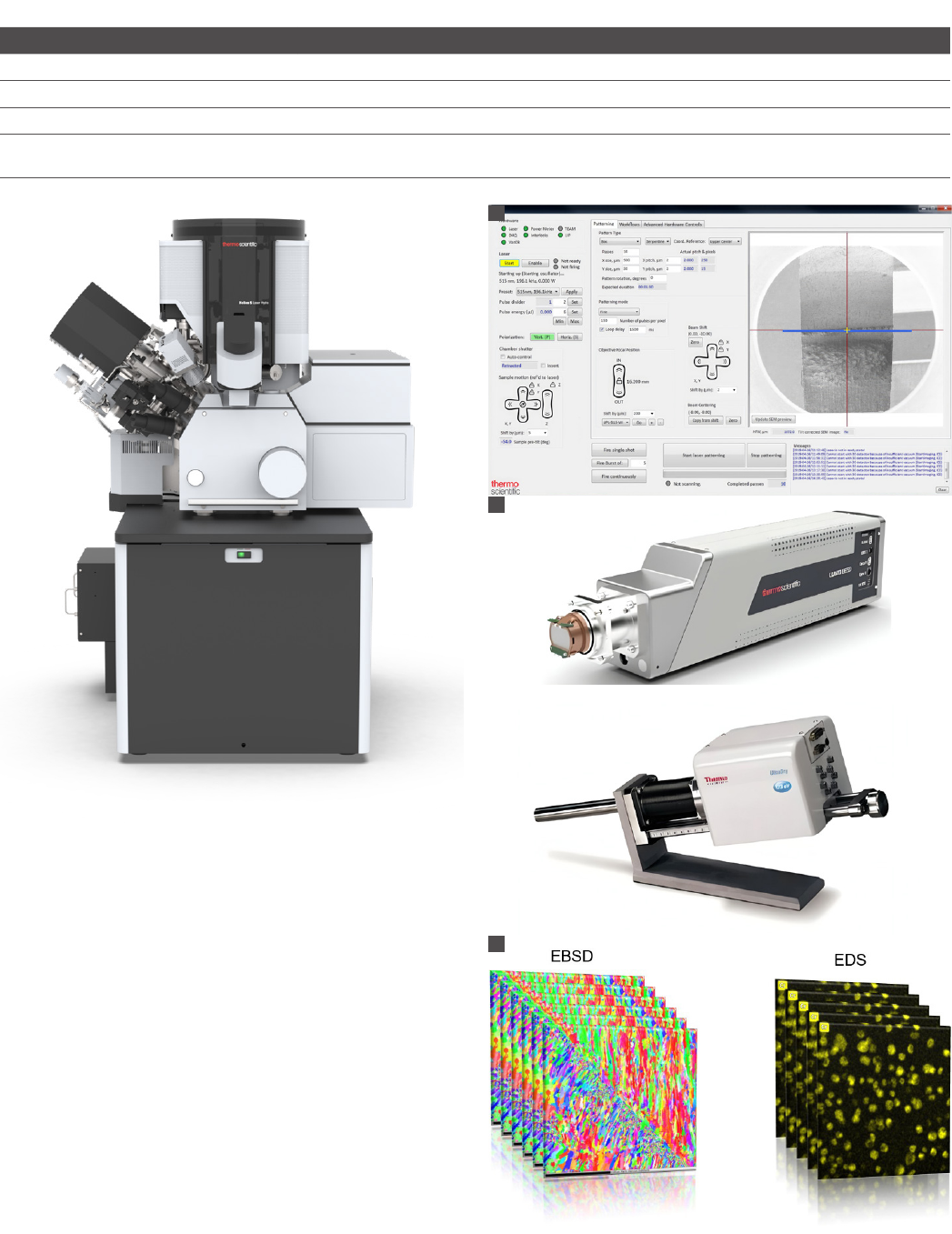

Femtosecond laser PFIB-SEM

The Helios Laser Hydra System is built on the fifth generation

of the Thermo Scientific

™

Helios Hydra

™

DualBeam platform

(Figure 5) and includes a fully enclosed femtosecond laser

optical path. The laser beam, electron, and multi-ion columns

are positioned on a plane and oriented toward a single point.

The fs-laser beam supports two wavelengths: 1030 nm (IR) and

515 nm (green). Fs-laser ablation is an athermal process that

enables material removal without thermal melting. In general

terms, thermal diffusion is slower than the Coulombic explosion

in femtosecond laser ablation, resulting in only a nanometer-

size heat-affected zone (HAZ). Material removal by the fs-

laser, meanwhile, is an order of magnitude higher than what is

possible with a Xe⁺ PFIB system.

Figure 2. 3D imaging methods for materials science. SST = serial

sectioning tomography.⁶

Figure 3. Serial sectioning techniques for 3D EBSD, including the size of

data collected, based on Reference 1. BIB = broad ion beam.

Figure 4. a) The 3D correlative microscopy/tomography workflow. Red

arrows indicate sample transfer, blue arrows mark data transfer. b) Cross-

platform holder/adapter kit. c) Sample and holder in the µCT. d) Sample

and holder in the Helios Laser Hydra System.

A

Sample preparation

Sample transfer

Data processing,

alignment, and

co-registration

Visualization, data

fusion, and mining

Multimodal data

acquisition,

micro sample

preparation,

STEM

Survey, high

resolution

scan, and ROI

navigation

Reconstructed CT volume

3D micro XCT

virtual sections

X-platform holder MicroCT

Helios 5 Laser Hydra

System Maps Software

Avizo Software

3D EBSD workflows

3D EBSD workflows are controlled and customized in the laser

UI (Figure 6a) or via Python scripting application programing

interface (API). These channels control acquisition hardware

(Figure 6b) and software. During an automated run, various 2D

datasets are sequentially collected (Figure 6c) and assembled

in 3D with Avizo 3D Software as well as any other EBSD

evaluation packages.

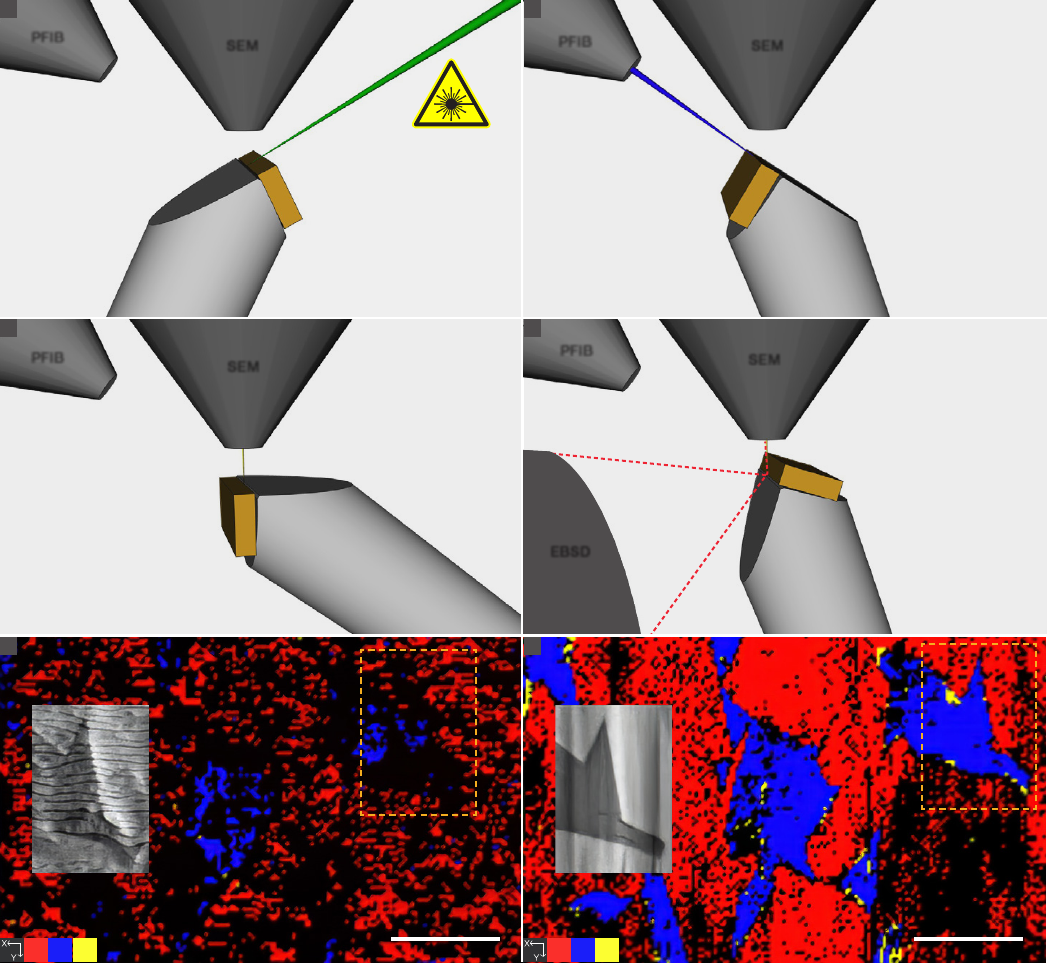

Laser PFIB-SEM stage positions for 3D EBSD data collection

(shown in Figure 7) are automatically cycled through as the data

is collected in sequence. Some materials require additional

surface polishing of the laser-ablated cross-section to remove

laser-induced periodic surface structures (LIPSS), as shown in

Figure 7e and 7f. These periodic structures can be suppressed

by fine tuning of laser parameters such as wavelength,

repetition rate, pulse energy, etc.

7,8

Figure 6. 3D EBSD with Helios Laser Hydra PFIB-SEM. A) Automation is

enabled with the laser UI or the Python scripting API.. B) Available EBSD

(top) and EDS (bottom) data acquisition hardware. C) Resulting multimodal

serial sections data.

Comparison of 3D EBSD parameters for various serial sectioning techniques

Ga FIB Xe PFIB Laser PFIB Xe PFIB SM* Broad IB Mech. Polish.

Slice thickness (nm) 5-50 25-500 250-10,000 1-1,000 10-10,000 200-10,000

Slice rate (µm³/s) 20 400 40,000 400 33 100,000-50,000

Max sample size (µm) 50x50 400x400 2,000x2,000 800x800 300x300 50,000x50,000

Damage depth (nm)

Si amorphisation

3-22 2.5 -13 20-50 2.5-13 <30 35-60

* Spin milling

A

B

C

Figure 5. The Thermo Scientific Helios Laser Hydra System.

Figure 7. Laser PFIB-SEM stage positions for 3D EBSD data collection. a) Layer removal with laser. b) Optional surface polishing with PFIB. c) SEM (EDS)

data mapping. d) EBSD (EDS) data collection. e) EBSD phase map of WC-11 wt% Co after laser ablation. SEM-SE inset shows the LIPSS pattern. f) EBSD

phase map after additional PFIB cleaning. SEM-SE inset shows PFIB polished surface.

Customer case study

Figure 8 shows correlative microscopy results from The

University of Manchester on stress corrosion cracking in an

AA7050 aluminum alloy, combining X-ray analysis with large-

volume 3D EBSD.²

Correlative microscopy was used to precisely locate regions

of interest and conduct multiple studies in order to better

understand the drastically different environmentally assisted

cracking (EAC) behaviors of the aviation and aerospace alloys

AA7050 and AA7085. For more experimental and scientific

details see Reference 2.

PFIB

SEM

~ 0 degrees

B

PFIB

SEM

~ 90 degrees

C

PFIB

SEM

~ 70 degrees

D

EBSD

PFIB

SEM

~ 0 degrees

A

CoCoWC

5 μm

E

CoCoWC

5 μm

F

Acknowledgements

We would like to thank Prof. Tim L. Burnett and Prof. Philip

J. Withers of The University of Manchester for allowing us to

highlight their work in this application note.

References

1. Echlin, MP, et al. Recent Developments in Femtosecond Laser-Enabled TriBeam

Systems. JOM 73, 4258–4269 (2021)

2. Garner, A, et al. Large-scale serial sectioning of environmentally assisted cracks in

7xxx Al alloys using femtosecond laser-PFIB. Mater Charact 188:111890 (2022)

3. Winiarski, B and Geurts, R. Laser Xe+ Plasma FIB-SEM: Correlative microscopy of

3D microstructures from nanometers to millimeters. Wiley Analytical Sci. Magazine

(2020)

4. Winiarski, B, at al. Correlative Tomography for Additive Manufacturing of Biomedical

Implants. Microscopy and Microanalysis 31(6), S4-S9 (2017)

5. Burnett, LT, et al. Correlative Tomography. Scientific Reports 4:4711 (2014)

6. Burnett, LT, et al. Large volume serial section tomography by Xe Plasma FIB dual

beam microscopy. Ultramicroscopy 161, 119-129 (2016)

7. Winiarski, B, and Geurts, R. Proceedings of the 6th International Congress on 3D

Materials Science, Washington, DC. (2022)

8. Jelinek, A, at al. A Perspective to Control Laser-Induced Periodic Surface Structure

Formation at Glancing-Incident Femtosecond Laser-Processed Surfaces. JOM 73,

4248–4257 (2021)

Summary

Correlative microscopy, combining µCT for site targeting

with laser PFIB-SEM for serial sectioning, allowed for precise

access to a large volume of material containing EAC cracks.

This high-resolution SEM study has provided new insight

into the interactions between microstructure and EAC cracks

in aluminum alloys, particularly in relation to the size and

morphology of the grains, as well as deviations in crack

direction. A novel, optimized lift-out procedure for large-scale

serial sectioning was also developed by researchers from

The University of Manchester, which can be used for similar

scientific and industrial research problems.

The Thermo Scientific Helios Laser Hydra System offers

researchers the unique opportunity to perform 3D analysis of

beam-sensitive and difficult-to-mill microstructures with sizes

ranging from nanometers to millimeters. This range of scales

helps bridge the gap between conventional Ga⁺ FIB and 3D

X-ray tomography. The Helios Laser Hydra System is ideally

suited for the correlative tomography workflow by coupling

micro X-ray CT with serial sectioning tomography while also

enabling multiple types of data (structural, crystallographic,

chemical, etc.) to be brought into registry for the same region.

D

570 µm

C

1 μm

B

3D-EBSD using femtosecond laser plasma FIB-SEMX-ray CT survey scan X-ray CT high-resolution scan

6 mm

A

60 mm

15 mm

6 mm

640

µm

660

µm

A B C

D

Figure 8. Correlation of X-ray CT datasets and laser serial sectioning for an AA7050 alloy.² a) Initial survey XCT scans with overlaid high-resolution ROI

scans of the crack tip region. The metal is rendered transparent, and the cracks are shown in dark blue. b) High-resolution ROI XCT scan with each

isolated crack feature colored differently (i.e., the crack front is split into separate fingers) within the volume. Approximate positions of the volumes

extracted for serial sectioning analysis are also shown. c) 3D reconstruction of the crack path (shown in dark blue). D) The entire 3D volume of the laser

serial sectioned specimen. Images were rendered in Dream 3D, freeware software for 3D EBSD post-processing and visualization. Data courtesy of The

University of Manchester, UK

For research use only. Not for use in diagnostic procedures. For current certifications, visit thermofisher.com/certifications

© 2023 Thermo Fisher Scientific Inc. All rights reserved. All trademarks are the property of Thermo Fisher Scientific

and its subsidiaries unless otherwise specified. AN0218-EN-04-2023

Learn more at thermofisher.com/tribeam