Pre-Feasibility Report

(PFR)

For

Proposed Downstream Petrochemical and

Coaltar Distillation Unit at Vill. Shyampur,

Mouza- Kalpaini, PO. Jambedia, PS.

Barjora, Dist. Bankura, West Bengal

By

M/s Odin Petroleum Products Pvt. Ltd.

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 2

CONTENTS

CH A P T ER 1 : INTR O D UCTI O N .......................................................................................................................... 4

1.1

Preamble ..................................................................................................................................................................................... 4

1.2

Identification of Project Proponent ........................................................................................................................................... 4

1.3

Employment Generation ........................................................................................................................................................... 6

1.4

Demand & Supply Gap .............................................................................................................................................................. 6

1.5

Legal Aspects ............................................................................................................................................................................. 7

CH A P T ER 2 : PROJ E C T DES C R I PTION ........................................................................................................ 8

2.1

Project Description ..................................................................................................................................................................... 8

CH A P T ER 3 : SITE ANALYSIS ........................................................................................................................ 17

3.1

Connectivity .............................................................................................................................................................................. 17

3.2

Land from Land use and Land ownership ............................................................................................................................ 17

3.3

Topography ............................................................................................................................................................................... 18

3.4

Soil classification ...................................................................................................................................................................... 19

3.5

Climatic data from secondary sources .................................................................................................................................. 19

3.6

Drainage pattern....................................................................................................................................................................... 19

3.7

Social Infrastructure available ................................................................................................................................................ 19

CH A P T ER 4 : PLAN N I N G BRI E F .................................................................................................................... 21

4.1

Planning Concept ..................................................................................................................................................................... 21

4.2

Population Projection ............................................................................................................................................................... 21

4.3

Land use planning .................................................................................................................................................................... 21

4.4

Assessment of Infrastructure Demand (Physical & Social) ................................................................................................ 21

4.5

Amenities/Facilities .................................................................................................................................................................. 21

4.6

Proposed Infrastructure ........................................................................................................................................................... 22

CH A P T ER 5 : REHABI L I TATI O N AND RESETTL EMENT ( R & R ) PLAN .......................................... 24

CH A P T ER 6 : PROJ E C T SCHE D ULE AN D COST ESTIM A T ES ............................................................ 25

6.1

Planning of Activities ................................................................................................................................................................ 25

6.2

Pre Project Activities ................................................................................................................................................................ 25

6.3

Project Activities (Implementation Stage) ............................................................................................................................. 25

6.4

Time Schedule for the Project ................................................................................................................................................ 25

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 3

6.5

Project Cost .............................................................................................................................................................................. 26

CH A P T ER 7 : ANAL Y S I S OF P R OPOS A L ................................................................................................... 27

7.1

Financial and social benefits .................................................................................................................................................. 27

7.2

Other Benefits ........................................................................................................................................................................... 27

AN N E X URE 1 : L A N D DOC U M E NT S ............................................................................................................. 28

AN N E X UR E 2 : P RO P OS ED P LANT L AY OUT ............................................................................................ 34

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 4

C

HAPTER

1:

I

NTRODUCTION

1.1 Preamble

M/s Odin Petroleum Products Private Limited is an unlisted private company. It was

incorporated on 27 September, 2019 and is located in West Bengal. It is classified as a

private limited company. The main line of business is Manufacture of Coke; Refined

Petroleum Products and Nuclear Fuel. The company is registered at JL NO. 113; KALPAINI

SHYAMPUR; BANKURA; Bankura; West Bengal; 722208; India. The company is promoted

by Sri Sapan Das, Sri Pradeep Newatia, Sri Milan Halder, Sri Chandan Gorai, Sri Santanu

Das. Promoters have a good experience in running a prototype unit since 1988 in the name

of M/S. Enbee Enterprises by Sri Pradeep Newatia and M/S. KMD ENTERPRISES by Sri

Sapan Das.

M/s Enbee Enterprises unit was shut down due to operational hazards as it was in Ghusuri

area of Howrah, West Bengal, due to space constraints and problem of no entry of vehicles.

Due to space constraints further expansion is not possible at the present scenario also new

products could not be included despite in house knowhow. Hence it is increasingly felt need

of setting up new unit in sophisticated manner on a bigger scale.

M/s Odin Petroleum Products Private Limited procured industrial land on lease hold basis

near Bankura, West Bengal. The land area is about 2998.68 sq.m.

M/s Odin Petroleum Products Private Limited proposes to implement Downstream

Petrochemical and Coaltar Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora,

Dist. Bankura, West Bengal.

1.2 Identification of Project Proponent

M/s Odin Petroleum Products Private Limited is promoted by Sri Swapan Kumar Das, Sri

Pradeep Newatia, Sri Milan Halder, Sri Chandan Gorai, Sri Santanu Das.

PROMOTERS

Sri Pradeep Kumar Newatia, aged about 62 passed B.Com (Hons.) from Kolkata University

in 1973 carrying on business in the name of M/s ENBEE ENTERPRISES, at 27, N.S. Road,

Kolkata 700001 since 1988. He was also having a chemical unit manufacturing similar

products at Ghusuri, Howrah since 1988 but now shut down last year, due to several

problems such as space constraint, pollution problem, No Entry of vehicles issues. Due to

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 5

densely populated area and unable to expand further, hence he along with his partners

plans to set up a bigger unit outside Kolkata. He is having practical and extensive working

experience in the business and good contacts with suppliers as well as customers.

Sri Swapan Kumar Das, aged about 56 years passed B.Com carrying on business in the

name of M/s KMD ENTERPRISE at Unara, Jambedia, Barjora, West Bengal. His company is

in manufacturing of Coal tar and solvents business since 2001. He possesses practical and

extensive working experience in the business and has good contacts with suppliers as well

as customers. He will be guiding force in this project with sound financial status.

He has considerable knowledge of all intricacies about the product and production process.

Sri Milan Halder, aged 38 years, passed B.E. in Chemical Engineering from Regional

Engineering college, Jaipur, Rajasthan, in the year 2002. He had handled various chemical

unit in senior capacity and now heading a large chemical plant in Nagpur since last 10 years.

He is having practical and wide working experience in the business and good contacts with

suppliers as well as customers.

Sri Chandan Gorai,

aged about 34 years, is in business since last 15 years.

He has handled coal tar plant in Durgapur and also acts as a contractor with sound financial

status.

Sri Santanu Das aged 26 years is well versed in production process and marketing.

In conclusion it is established that all the five directors are technically competent and

business minded, experienced in their field and financially stable.

Project is being set up with a vision to Growth. If everything goes per plan then promoters

will go for further expansion in next three years. The required land for expansion is available

in vast stretches just beside the procured factory land. There are all possibilities as because

there is a huge demand of our products in the market to our existing customers as well as

new one which we could not tap due to production constraints.

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 6

Project Proponent:

Name of the Company M/s Odin Petroleum Products Private Limited.

Registered Address M/s Odin Petroleum Products Private Limited

Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist.

Bankura, West Bengal

Address for correspondence M/s Odin Petroleum Products Private Limited

Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist.

Bankura, West Bengal

Name of the Applicant Swapan Kumar Das

Designation (Owner/ Partner/ CEO) Director

E-mail

swapandas01011961@gmail.com

Telephone No. +91 8436338732

1.3 Employment Generation

During the construction phase approx 50 persons will be required and will be sourced from

local area.

It is estimated that about 15-20 personnel will be employed during operational phase of the

Downstream Petrochemical and Coaltar Distillation Unit. Indirect employment is also likely to

be generated with the proposed project which will be economically beneficial for the

development.

1.4 Demand & Supply Gap

Solvent and Coal tar processing plants are having a very bright future in a developing

country like India. Raw materials are available from number of oil refineries and steel plants

indigenously.

Solvents and Thinner are widely used in Paints & Printing ink, Pesticides & Rubber

industries etc. We will be making anti corrosive paints based on coal tar which is widely used

in coating of underground pipe lines by ONGC, Ship Bottoms, automobiles, Railways, and

Defense etc.

Spray oil requires in Tea garden and apple estate for pesticides. The Project offers

employment for 15-20 person. Necessary technical knowhow developed in house and do not

depend outside help. Past experience is an added advantage. Necessary R&D will be

simultaneously carried out to add new products. Raw materials are available indigenously

mainly from oil Refineries and steel plants.

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 7

1.5 Legal Aspects

The relevant NOC’s and licenses will be obtained from the statutory agencies under the

following Acts, Rules and amendments and M/s Odin Petroleum Products Pvt. Ltd. (OPPPL)

will adhere to the guidelines specified in.

OPPPL will comply with the prescribed limits laid down for air, effluent and noise emissions

for protection of the environment under the following Acts, Rules and amendments:

1. The Water (Prevention and Control of Pollution) Act, 1974

2. The Water (Prevention and Control of Pollution) Cess Act, 1977

3. The Air (Prevention and Control of Pollution) Act, 1981

4. The Environment (Protection) Act, 1986 which is also called umbrella act or

legislation

5. The Environment Impact Assessment, Notification, 2006 issued under Environment

(Protection) Act 1986 and Environment (Protection) Rules 1986 and amendments

thereafter to date.

Compliance to State Rules and Notifications will also be ensured.

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 8

C

HAPTER

2:

P

ROJECT

D

ESCRIPTION

2.1 Project Description

I. Type of Project including interlinked and independent projects, if any

There are no interlinked or inter dependent projects.

Major process consists of fractional distillation, filtration, and blending. Products are to be

tailor made as per specifications of Industrial customers which differs from case to case.

II. Location (map showing general location, specific location, and project boundary &

project site layout) with coordinates:

The total area of proposed plant of OPPPL is about 2998.68 sq.m and has the coordinates

as per given hereunder:

Table 2.1: Coordinates of the Plot area

Points

Coordinates

Latitude

Longitude

A 23°21'32.58"N 87°14'9.57"E

B 87°14'10.74"E 87°14'10.74"E

C 23°21'29.97"N 87°14'10.13"E

D 23°21'30.68"N 87°14'8.51"E

The location of the project area is shown in Figure 2.1.

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 9

Figure 2.1: Location map of Project site

Communication

It’s well linked with other parts of the country by all the three major modes of transportation –

rail, road and sea. It lies on the railway line connecting Asansol-Durgapur-Howrah (Eastern

Railway). It is well-reachable by trains from both Howrah Station and Sealdah Station at

Kolkata and Asansol Station.

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 10

The place is linked by Bankura road, NH-2 or Delhi Road and Mumbai Road. The National

Highway (NH-2) between Durgapur and Kolkata is about 15 Km distance from the proposed

project site.

III. Key Plan

The layout plan for proposed plant attached as Annexure 1.

IV. Details of alternative site consideration and basis of selecting the proposed site

particularly the environmental considerations gone sound be highlighted.

No Alternative Sites are considered as the vacant land has been procured in the said

industrial belt.

V. Size or magnitude of operation

The proposed project will be production of 3060 TPA Downstream petrochemical and coaltar

distillation unit. Location of plot coordinates is provided below:

Points

Coordinates

Latitude

Longitude

A 23°21'32.58"N 87°14'9.57"E

B 87°14'10.74"E 87°14'10.74"E

C 23°21'29.97"N 87°14'10.13"E

D 23°21'30.68"N 87°14'8.51"E

The estimated project cost is about INR 270.6 Lakhs.

Figure 2.2: Location of Project site

Table 2.2: Land area breakups

Sl.No

Details

Total Area in Sq. m

Area as % of Total

1 Plant/processing area 345 11.5%

2 Storage area 120 4.0%

3 Roads and Walkways 244 8.1%

4 Admin building 99 3.3%

5 Open space area 1101.68 36.7%

6 Green Belt area 989 33.0%

7 Other Utilities 100 3.3%

Total

2998.68

100.0%

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 12

VI. Project description with process details (a schematic diagram/ flow chart showing

the project layout, components of the project etc. should be given)

Major process consists of fractional distillation,filtration, and blending. Products are to be tailor

made as per specifications of Industrial customers which differs from case to case.

Crude

Lab Test

Distillation

Blending

Filtration

Lab Test

Despatch

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 13

Distillation of Petroleum byproducts will be raised under Batch processing system at different

temperature which may go up to 400*c. various fractions will be collected separately to make

different products. Filtration is done to remove foreign particles in the product and make

quality products in the process. Ash contents, Toluene insoluble, Benzene insoluble are very

tough criteria where we have to be very alert.

Blending is a fine art to produce tailor made products for different customers as per their

specifications. This is a very important process which takes place before and after distillation.

Processing of coaltar is simple batch distillation. We will dehydrate the product Coaltar and

remove moisture content. Temperature will be raised up to 150°C approx to remove moisture.

Necessary oils and other solvents to be added to make it Perfect Dehydrated coaltar which will

be used by paints unit. Filteration and blending is important part to it.

LAB TEST

We have to set up a sophisticated laboratory in the plant. Which will be under supervision of a

experienced chemist

Every Raw material has to be tested at the time of arrival. Normally Moisture, Boiling range, sp

gravity, aromatics and foreign materials has to be judged.

During process batch sample has to be tested to confirm the quality in process.

Typical analytical report has to prepare before every dispatch to ensure quality material.

We have to deal with large industrial customers who are very particular about quality checking.

Hence we have to be very careful in this matter.

STORAGE

Material in liquid condition will be kept in storage tanks which will be either underground or

above ground. We will take approval of explosive department for storage of petroleum product.

Material will be handled through Pumps and Motors.

Viscous material will be also kept in barrels for easy handling.

DESPATCH

Finished products will be dispatched in tank Lorries or in steel prove barrels as per customer

orders.

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 14

CARE FOR POLLUTION

OPPPL will take care that there will be no discharge of any sort of effluent in water. There will

be no such emission and the entire process is in closed system.

Adequate stack height will be provided. No discharge of any toxic harmful substance in water

is anticipated. The process effluent will be treated in ETP and treated water will be used for

cooling of material and will be recycled through cooling system. A cooling system will be in

place.

There will be reuse of residual portion also, so no wastage of any sort will be allowed.

Necessary instrumentation will be set up for the same.

VII. Raw material required along with estimated quantity, likely source, marketing area

of final products, mode of transport of raw material and finished product.

List of raw materials

Sl.No

Raw materials

Quantity

(in TPA)

Form

Transportation

Source

Storage

1 Crude Benzole 600 Liquid Tanker DSP/TATA MS Tank

2 Aromax 720 Liquid Tanker Reliance MS Tank

3 MFO 240 Liquid Tanker GAIL MS Tank

4 Slop oil 600 Liquid Tanker Reliance MS Tank

5 Crude Coal Tar 1080 Liquid Tanker Bhilai/DSP/

TATA

Tank

VIII. Resource optimization/ recycling and reuse envisaged in the project, if any, should

be briefly outlined.

Maximum care will be taken for resource optimization, wherever possible with an aim of Zero

discharge”.

Resource Conservation

Elimination of Waste Streams

Minimizing Waste

Reuse of Wastes

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 15

Recycle of Wastes

Treatment and Disposal for making wastes harmless

Wash water generated from cleaning of equipment’s will be re-used back into the

process.

IX. Availability of water its source, energy /power requirement and source should be

given.

Water requirement

The requirement of water for operation of the Plant is tentatively 5 KLD. This will be fulfilled by

drawing water from DVC supply.

Table 2.3: Water Consumption Details (KLD)

Sl. No

Area of consumption

Water demand (KLD)

1 Processing 2.0

2 Cooling tower 1.0

3 Boiler 0.5

4 Gardening 0.5

5 Domestic 1.0

Total

5.0

Power Requirement

The power requirement estimated to be about 100 KW (Source – West Bengal State Electricity

Distribution Company Limited). DG sets of 125 KVA DG set (1 No.) proposed for back up

power. Fuel Quantity (for existing DG sets and others) will be about 0.4 KLD.

Fuel Requirements & Storage

Estimated consumption of HSD shall be about 0.4 KLD and shall be stored in drums of 1000

liters.

X. Quantity of waste to be generated (liquid and solid) and scheme for their

management/disposal

As per present scheme, no process waste will be generated, if in case generated shall be

stored and disposed off at Treatment Storage and Disposal Facility (TSDF) approved by West

Bengal State Pollution Control Board (WBPCB).

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 16

Liquid Waste:

Wastewater generation will be 3 KLD (2.5 KLD Industrial + 0.5 KLD Domestic). Industrial

wastewater will be treated in 5 KLD ETP and domestic wastewater will be treated in septic

tank and soak pits. ETP will be provided as per latest available technology.

Solid & Hazardous Waste:

There will be no generation of solid & hazardous waste in normal operation. Spent oil will be

sent to the specialized vendor for treatment/ regeneration/ recycle.

Table 2.5: Hazardous waste details per well

Sl.No.

Hazardous waste

Quantity

Method of disposal

1 Used/ spent oil, Oil

sludge

500 Litre/

Annum

Used oil will be collected in metal drums kept in

secured dyked area and will be disposed to

CPCB/ WBPCB registered used oil reprocessor

2 Wastes/ residues

containing oil

5 Kg/

Month

Disposed on-site in HDPE lined pits located on

site

3 ETP sludge 30

Kg/Month

Will be disposed through TSDF authorized by

WBPCB/CPCB

4 Discarded

containers

200

no.s/year

Outside agency for Recycling

Table 2.6: Non Hazardous Waste details and disposal methods

Sl.No.

Non Hazardous

waste

Quantity

Method of disposal

1 Recyclable

waste like

papers, plastics,

2 Kg/month Proper segregation and storage of

recyclable waste in designated bins

onsite. Recyclables will be periodically

sold to local waste recyclers.

2 Metal Scraps 300 Kg/month Will be sold to local recyclers

3 Packaging

wastes

Small Proper segregation and storage at

designated stackyard onsite. Packaging

wastes will be periodically sold to local

waste recyclers.

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 17

C

HAPTER

3:

S

ITE

A

NALYSIS

3.1 Connectivity

The proposed Downstream Petrochemical and Coaltar Distillation Unit will be set up at Vill.

Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal.

Communication

Project site is well linked with other parts of the country by all the three major modes of

transportation – rail, road and sea. It lies on the railway line connecting Asansol-Durgapur-

Howrah (Eastern Railway). It is well-reachable by trains from both Howrah Station and

Sealdah Station at Kolkata and Asansol Station. Durgapur-Barjora road is passing beside the

proposed site.

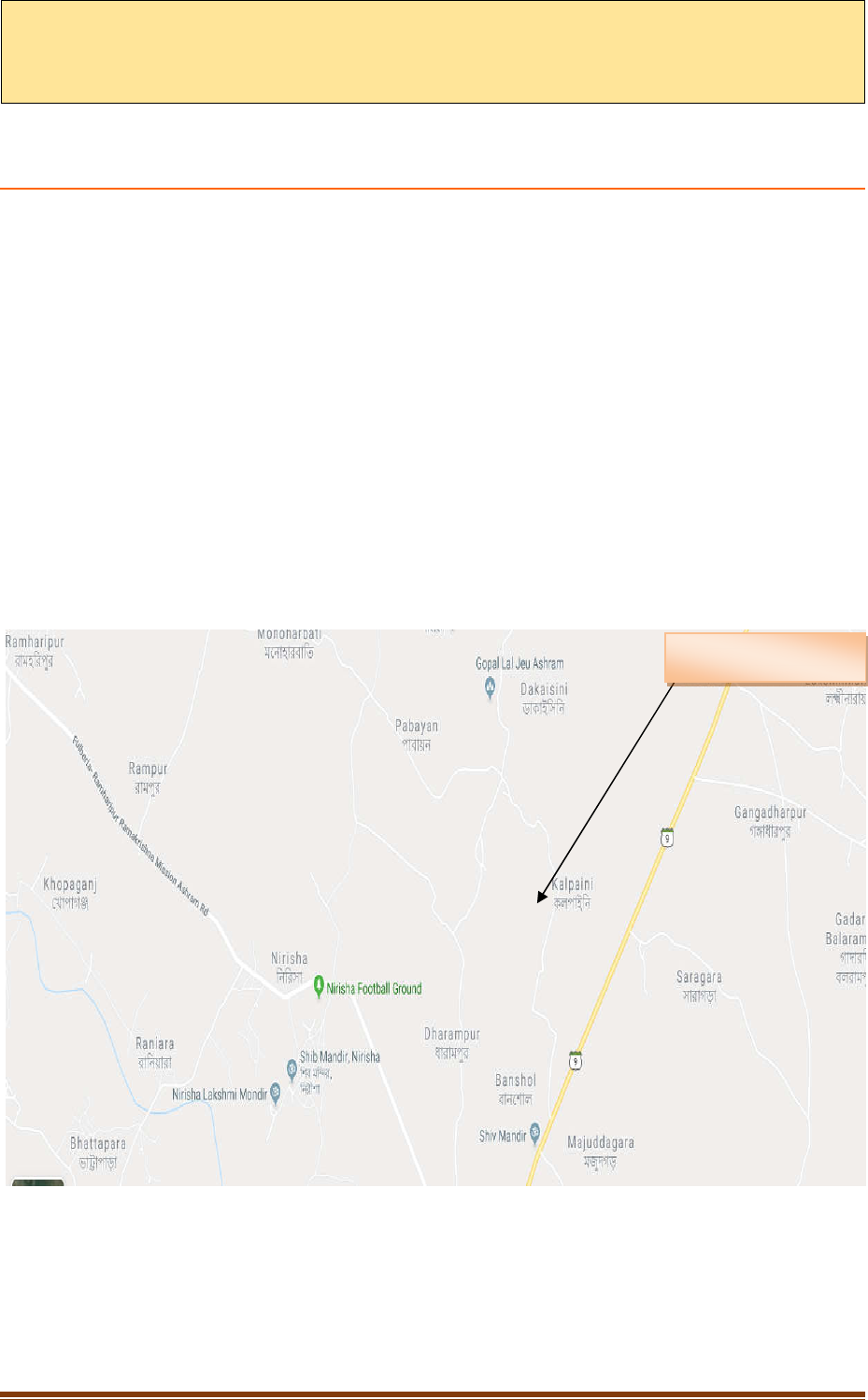

The map showing the road network around the site is given in Figure 3.1.

Figure 3.1: Connectivity shows in the map

3.2 Land from Land use and Land ownership

The area of proposed plant is 2998.68 sq.m plot at Dag no. 242, Khaitan no. 302, JL. No- 113

under Mouza- Kalpaini.

Site Locations

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 18

3.3 Topography

Bankura is located in the western part of the State of West Bengal. It is a part of Bardhaman

Division of the State and included in the area known as "Rarh" in Bengal. It ranks 4th

according to Population and literacy rate of 2001 Census in the State. The District Bankura is

bounded by latitude 220 38’ N and longitude 860 36’ E to 870 47’ E. River Damodar flows

along the northern boundary of the district. The adjacent districts are Bardhaman in the north,

Purulia in the west and Paschim Medinipur in the south.

.

Bankura district

The district of Bankura is covered by crystalline rocks of Precambrain age. Granite gneiss,

mica schirt, anothosite etc are the principle types of rock exposed in this part. The project area

lies within a thick mantle of laterite generally mountainous and undulating. The average height

of high physiographical areas varies from 55 to 106 m above Mean Sea Level (MSL).

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 19

3.4 Soil classification

The western part of the district has poor, ferruginous soil and hard beds of laterite with scrub

jungles and sal woods. Long broken ridges with irregular patches of more recent alluvium

have marks of seasonal cultivation. During the long dry season large extents of red soil with

hardly any trees lend the country a scorched and dreary appearance. In the eastern part the

eye constantly rests on wide expanses of rice fields, green in the rains but parched and dry in

summer. The Gondwana system is represented in the northern portion of the district, south of

the Damodar, between Mejia and Biharinath Hill. The beds covered with alluvium contain

seams of coal belonging to the Raniganj system.

3.5 Climatic data from secondary sources

The climate of the project area is humid and tropical. It is characterised by a hot and dry

summer from March to May and south-west monsoon or rainy season from June to

September, a pleasant post-monsoon or retreating monsoon from October to November and a

cool winter from December to February. Therefore, climatologically, four seasons viz. summer

(pre-monsoon), monsoon, post-monsoon and winter.

3.6 Drainage pattern

Hydrological condition at a particular point is guided by topography, geology, and rainfall

(Annual rainfall 1400 mm) of the region. Under uniformly excellent water aquifer condition

groundwater simulates topography. The ground water resource is potential over all

geomorphic surface of the region. The dug wells, tanks, water bodies with jhor bunds, river

valleys are ideal sites for recharging ground water of the region. Bankura drained by the rivers

of Kangsabati, Kumari, Shilabati, Keleghai, Dwarakeswar and their tributaries.

3.7 Social Infrastructure available

No archaeologically important monument, arts and cultural site exist on either side of the

project within 10 Km study area. There are no such Areas protected under international

conventions, national or local legislation for their ecological, landscape, cultural or other

related values as well as Areas used by protected, important or sensitive species of flora or

fauna for breeding, nesting, foraging, resting, over wintering, migration.

The nearest city is Durgapur which is about 15 Km from the project site and is densely

populated.

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 20

Irrigation and agriculture are directly correlated with each other. The necessity for expanding

irrigation to stabilize Indian agriculture and to prevent the food scarcities that hits the economy

during the Pendency of the second and third plans is well recognized. Although irrigation

impact varies between states and regions, primarily because of climatic factors, there is

agreement on the objective indices of impact-measurement. Introduction of irrigation therefore

has positive effects on agriculture yields, cultivated areas and the size of the resultant output,

while also being accompanied by changes in cropping patterns. Irrigation provides insulation

against weather related crop fluctuation by stabilising farm output and generates enhanced

agriculture employment, especially in the initial phases where it is not accompanied by farm

mechanization.

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 21

C

HAPTER

4:

P

LANNING

B

RIEF

4.1 Planning Concept

As per EIA Notification dated 14

th

September, 2006, as amended on 25

th

June 2014, the

project falls under activity ‘5(e)’ category ‘A’ project. So the Proposed project will be appraised

at MOEF&CC.

4.2 Population Projection

Direct and indirect employment will be created due to project. Due to proposed project it is

envisaged that around 20 personnel will be employed including skilled and unskilled labour.

4.3 Land use planning

The proposed project will be implemented at the identified land; there will no alteration in the

land use of the study area. Building for manufacturing process for proposed Petrochemical

and Coaltar Distillation Unit plant will be located within identified plant premises. Total plot

area is 2998.68 sq.m only.

4.4 Assessment of Infrastructure Demand (Physical & Social)

No additional land will be acquired for proposed project. Existing facilities at the area will be

used for transportation and communication. The raw material and product storage facility,

utilities & ETP facility will be implemented at the proposed plant.

4.5 Amenities/Facilities

The amenities/ facilities will be available.

Potable drinking water

Firefighting/ alarm system and ambulance is available in case of emergency

Drinking water, canteen and electricity facilities is provided

Separate sanitation facilities will be provided for men and women.

PPE’s and facilities related to safety will be provided.

Occupational Health Centre with qualified doctor is available for periodical health

check-up of employees.

Greenbelt will be developed within 989 sq.m of area (33% of total plot area).

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 22

4.6 Proposed Infrastructure

The proposed project will involve construction of new plant for manufacturing of Downstream

Petrochemical and Coaltar Distillation Unit. About 33% of total 2998.68 sq.m of land is

identified for green belt development. Utilities, raw material & product storage, effluent

treatment facility will be developed.

Cooling Tower

A twin cell cross flow induced draft Cooling tower will have to be built for the proposed project.

2 nos. of motor driven Cooling Water pumps will be provided.

Compressed Air system

The compressed air system consist of two Compressors and an Air receiver required to supply

pre treated dry air to different consumers throw out the plants, off-sites and utilities. Normally

only one compressor shall run. Air pressure is controlled by a sequence controller.

Control Room & Instrumentation

A common Control Room has been considered for the process operations of the Proposed

Downstream Petrochemical and Coaltar Distillation Unit Plant and all utility / auxiliary units

comprising the Complex. A new building for the Control Room with offices for the Shift

Engineer, Manager and Shift Technicians as well as Change Room and toilet facilities needs

to be constructed.

Quality Control & Analytical Laboratory

The Plant shall require regular measurement of quality of following feedstock/ raw materials as

well as final products, with necessary certifications. Besides process controls will require

quality measurements of the intermediate products, to control and adjustments of the process

parameters.

For ease in operation, it is proposed that the laboratory be located in close proximity of the

control room.

Storage & Warehouse

A maintenance building is envisaged for maintenance of pumps, valves, motors and

instruments of the Plant. The offices of maintenance personnel and documentation room are

also placed in this building.

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 23

Maintenance workshops

A maintenance building is envisaged for maintenance of pumps, valves, motors and

instruments of the Plant. The offices of maintenance personnel and documentation room are

also placed in this building.

Administrative Building

Customarily Administrative building block is located outside security fence of the factory

premises to enable hassle-free access to the visitors, not needing factory zone access. The

building shall be located close to the main entry gate, and at safe distance from the explosive

factory zone.

Industrial Wastes/Waste Water Management:

Effluent:

Normally there is no generation of wastewater from process, however intermittent generation

of wastewater will be treated in Effluent Treatment Plant (ETP). About 100% of effluent

generated shall be reused with the raw material input. Wastewater generation will be 3 KLD

(2.5 KLD Industrial + 0.5 KLD Domestic). Industrial wastewater will be treated in 5 KLD ETP

and domestic wastewater will be treated in septic tank and soak pits. ETP will be provided as

per latest available technology.

Air Emission:

Adequate stack height will be provided to all flue gas stacks. Stack emission quality will be

maintained as per the applicable norms.

A. Diesel Generators

Diesel will also be used to run the D.G. set for backup power supply and it is estimated that

the unit will need diesel as 0.4 KLD of HSD.

No. of stacks 1

Attached to DG Set

Capacity 125 KVA (1 No)

Fuel Type HSD

Fuel Quantity 0.4 KLD

Material of Construction M.S

Shape Round

Height 12 m

Solid Waste Management:

There will be no generation of solid & hazardous waste in normal operation.

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 24

C

HAPTER

5:

R

EHABILITATION AND

R

ESETTLEMENT

(R

&

R)

P

LAN

I. Policy to be adopted (Central/State) in respect of the project affected persons

including home oustees, land oustees and landless labourers

The proposed project is going to come up on 2998.68 sq.m area. There is no existence of

displaced habitants in the identified land. Local people will be engaged for construction

activities and the local area has all the associated and supportive infrastructure facilities.

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 25

C

HAPTER

6:

P

ROJECT

S

CHEDULE AND

C

OST

E

STIM ATES

6.1 Planning of Activities

Careful planning of all the activities is one of the pre-requisite for timely completion of the

project. Following activities will be given special attention. In house technical studies are in

progress for log interpretation and evaluation of the formation and potential zone.

It is planned to start project after getting Environment Clearance from Ministry Environment,

Forest & Climate Change (MoEF&CC), and Consent from West Bengal Pollution Control

Board. The total time for the execution will be about 12 month.

6.2 Pre Project Activities

Management Approvals

Selection of location

Statutory Clearances

Financial Approvals

Conceptual Design

6.3 Project Activities (Implementation Stage)

Firm up basic design

Detail Engineering

Preparation of tender, evaluation of tenders received and order placement for

equipment

Completion of procurement activities

Civil construction

Inspection of major machinery at supplier’s works

Supply of equipment

Erection of Machinery

Pre-/commissioning and start up

6.4 Time Schedule for the Project

The zero date for start of construction will be after grant of Environmental Clearance (EC) from

MoEF&CC. The proposed construction activities will be completed within 12 months after

issuance of EC. The external agencies such as consultant, machinery suppliers, contractors of

civil construction and equipment will be selected carefully well in advance. An effective project

team has been formulated with an experienced project manager as its leader.

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 26

6.5 Project Cost

Estimated project cost along with analysis in term of economic viability of the

project

The total investment for the proposed project works out to approximately INR 270.6 Lacs. The

estimated Investment Cost for the project is based on the requirement of fixed and non fixed

assets.

Sl.N

o.

Particulars / activities

Capital Cost in Lacs INR

1 Plant & Machinery 120.0

2 Land & Site development 9.2

3 Building & other civil works 11.0

4 Preliminary & Preoperative Exp. 5.0

5 Detailed Engineering & consultancy 5.0

6 Office equipment & Furniture 1.0

7 Working capital margin 22.9

8 Contingency 5.0

9 Working capital 91.5

Total Project cost

270.6

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 27

C

HAPTER

7:

A

NALYSIS OF

P

ROPOSAL

7.1 Financial and social benefits

Financial and social benefits with special emphasis on the benefit to the local

people including tribal population, if any, in the area

Downstream Petrochemical and Coaltar Distillation Unit plant will result in growth of the

surrounding areas by increasing direct and indirect employment opportunities in the region

including ancillary development and supporting infrastructure. Special emphasis on financial

and social benefits will be given to the local people in the area.

Employments to the local people

Social activities such as support for primary school, etc

7.2 Other Benefits

Development of the local area in terms of an enlarged market.

Besides above, indirect benefits have also occurred to the region by way of increase in

industrial production.

Thus, the proposed project will ushered in the social and economic upliftment of the persons

living in the vicinity of the Project i.e. of society at large.

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 28

A

NNEXURE

1:

L

AND

D

OCUMENTS

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 29

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 30

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 31

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 32

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 33

Pre-Feasibility Report (PFR) For Proposed Downstream Petrochemical and Coaltar

Distillation Unit at Vill. Shyampur, PO- Jambedia, PS. Barjora, Dist. Bankura, West Bengal

By M/s Odin Petroleum Products Pvt. Ltd.

Page 34

A

NNEXURE

2:

P

ROPOSED

P

LANT

L

AYOUT