MLE+: A Tool for Integrated Design and Deployment of

Energy Efficient Building Controls

∗

Willy Bernal, Madhur Behl, Truong X. Nghiem, Rahul Mangharam

Department of Electrical and Systems Engineering

University of Pennsylvania

{willyg,mbehl,nghiem,rahulm}@seas.upenn.edu

Abstract

We present MLE+, a tool for energy-efficient building au-

tomation design, co-simulation and analysis. The tool lever-

ages the high-fidelity building simulation capabilities of Ener-

gyPlus and the scientific computation and design capabilities

of Matlab for controller design. MLE+ facilitates integrated

building simulation and controller formulation with integrated

support for system identification, control design, optimization,

simulation analysis and communication between software ap-

plications and building equipment. It provides streamlined

workflows, a graphical front-end, and debugging support to

help control engineers eliminate design and programming er-

rors and take informed decisions early in the design stage,

leading to fewer iterations in the building automation develop-

ment cycle. We show through an example and two case studies

how MLE+ can be used for designing energy-efficient control

algorithms for both simulated buildings in EnergyPlus and real

building equipment via BACnet.

Categories and Subject Descriptors

I.6.3 [Simulation and Modeling]: Applications; D.2.2

[Software Engineering]: Design Tools and Techniques; J.7

[Computer Applications]: Computers in Other Systems

General Terms

Design

Keywords

Building simulation, building control, control design, ener-

gyplus, energy-efficient building, integrated design, matlab

1 Introduction

In the design of energy-efficient buildings, systems engi-

neers require both, tools capable of simulating high-fidelity

plant models, and tools to design, evaluate and deploy mod-

ern control methods on those plant models. There is currently

a significant gap between the functionality of the tools avail-

able for building energy research. While simulation tools can

∗

This material is based upon work supported by the DoE Energy Efficient

Buildings HUB sponsored by the Department of Energy under Award Number

DE-EE0004261.

Permission to make digital or hard copies of all or part of this work for personal or

classroom use is granted without fee provided that copies are not made or distributed

for profit or commercial advantage and that copies bear this notice and the full citation

on the first page. To copy otherwise, to republish, to post on servers or to redistribute

to lists, requires prior specific permission and/or a fee.

Buildsys’12, November 6, 2012, Toronto, ON, Canada.

Copyright © 2012 ACM 978-1-4503-1170-0 ...$10.00

accurately simulate the behavior of a building and its energy

consumption, their capabilities for advanced control design

and optimization are inadequate. This is, in part, is due to

the limited interaction between building modeling and simu-

lation experts and the control systems engineers community.

Consequently, as these research communities form tighter col-

laborations, there is a need for software tools for end-to-end

design of energy-efficient building control systems. This will

not only influence how architectural design choices directly af-

fect the operational efficiency of building automation systems,

but also facilitate the co-design of high-performance control

systems for the specific building model. The focus of this ef-

fort is on the development of MLE+, a co-simulation tool, that

utilizes the simulation capabilities of building energy software

tools such as EnergyPlus while taking full advantage of the

Matlab environment for control design.

Building simulation tools like EnergyPlus [1], TRN-

SYS [2], ESP-r [3], eQuest [4], DOE-2 [5] and Design-

Builder [6] offer powerful methods for simulating realistic be-

havior of buildings and for evaluating their energy efficiency

and sustainability. These tools use high fidelity physical mod-

els for heat conduction through surfaces, heat and mass trans-

fer, coupling of air and water loops, thermal comfort, fenes-

trations, daylighting control, weather conditions, atmospheric

pollution, occupancy and Heating Ventilation and Air Condi-

tioning (HVAC) equipment. Using increasingly detailed de-

scriptions of a building, one can obtain an estimate of the

building’s energy requirements in terms of heating and cool-

ing loads, interior environmental conditions and building au-

tomation operation cost. Although building simulation tools

can run high-fidelity simulations, they have limited capabil-

ity for algorithm development, optimization, control synthesis

and model-based system design.

EnergyPlus [1] is one of the most robust building energy

analysis and thermal load simulation tools available today and

it has become the de facto whole building simulation tool sup-

Figure 1. MLE+ interfaces control systems toolboxes with

building models and systems

ported by the U.S. Department of Energy. It is a stand-alone

simulation engine which processes text-based input files to run

realistic building simulations. It allows simultaneous simula-

tion of loads, systems, and plant and therefore permits quick

assessment of building performance. The most recent ver-

sion also supports coupling with Functional Mock-up Units

(FMUs) for co-simulation [7], which allows extending Ener-

gyPlus with custom simulation code in the C language. It pro-

vides a built-in energy management system that allows inte-

gration of simple rule-based control.

However, EnergyPlus lacks the capability to directly inter-

face with scientific computation and simulation software such

as Matlab and Simulink. Therefore, it is difficult to imple-

ment and simulate advanced control feedback strategies such

as Model Predictive Control (MPC)[8], where an optimal con-

trol signal is repeatedly computed based on the current state of

the controlled plant. It requires considerable effort and time

for a control expert to obtain working knowledge of Energy-

Plus, become familiar with its elaborateness and use it for im-

plementing advanced control algorithms. Thus, we identify

the following desired capabilities of such a co-design and co-

simulation tool:

• Support high fidelity building simulation software and

standard scientific computation software.

• Have the capability to compare and rapidly simulate

scenarios of different control algorithm implementations

across a range of building model parameters. This helps

in taking informed decisions during the early phases of

design.

• Facilitate common tasks in energy-efficient building de-

sign, such as identifying and validating simplified models

from high order physical models, optimizing parameters

of a building model, designing advanced controllers and

their quantative analysis for a building.

In this paper, we present MLE+, an open-source Mat-

lab/Simulink toolbox for building energy research and devel-

opment (Fig. 1). MLE+ provides the capability to perform co-

simulation with EnergyPlus from Matlab. Co-simulation (or

co-operative simulation) is a simulation methodology that al-

lows individual components to be simulated by different tools

running simultaneously and exchanging information in a col-

laborative manner. The following are the main features of

MLE+:

1. Simulation configuration: The MLE+ front-end stream-

lines the configuration process of linking the building

model and the controllers by abstracting the necessary pa-

rameters from the co-simulation. This reduces setup time

and configuration problems.

2. Controller design: MLE+ provides a control develop-

ment workflow as well as graphical front-ends for de-

signing advanced control strategies, in which the building

simulation is carried out by EnergyPlus while the con-

trollers are implemented in Matlab or Simulink.

3. Simulation-based optimization: MLE+ can be used to

find optimal parameters or control sequences for building

system simulations in EnergyPlus.

4. Data analysis: After a co-simulation run, using MLE+,

the output data from EnergyPlus can be aggregated, ana-

lyzed and visualized in Matlab.

Figure 2. MLE+ tool interface

5. Building Management System Interface: MLE+ pro-

vides a BACnet interface to develop and implement con-

trol methods for real building equipment.

6. Matlab environment: MLE+ allows complete access to

the Matlab environment and toolboxes such as Global

Optimization Toolbox, System Identification Toolbox

and Model Predictive Control Toolbox. The user can

step through the code for debugging and pause the co-

simulation at any time.

The rest of the paper is structured as follows. We first

present a running example of using MLE+ for designing a con-

troller for co-simulation with EnergyPlus. Section 3 describes

the architecture of MLE+. Two case studies using MLE+ are

presented in sections 4 and 5. We conclude the paper with re-

lated work in section 6, use cases of MLE+ in section 7 and a

discussion in section 8.

2 Using MLE+: A Simple Example

To explain the usefulness of MLE+, we use an example

of designing a feedback controller in MLE+ for actuating the

window blinds in a building simulated in EnergyPlus.

A single-storied building shown in Fig 3(a) consists of three

zones with a total floor area of 130m

2

. The West zone of

the building consists of a large window equipped with blind-

s/shades and is subject to strong solar radiation during the

day. The goal is to control the window shade deployment

of the West zone such that the transmitted solar radiation

through the window never exceeds a certain threshold. The

window blinds can be controlled using two EnergyPlus vari-

ables: (i) Shading_Deployment_Status controls whether the

blinds are deployed or not; (ii) ShadeAngle_Schedule con-

trols the glare inside the zone and should be perpendicular to

the incident solar radiation whenever the blinds are deployed.

We will design a controller in MLE+ which monitors the an-

gle and intensity of the solar radiation incident on the West

zone window. If the incident solar radiation exceeds a certain

threshold, the blinds will be deployed and the shade angle will

be set to reduce the possibility of glare.

2.1 Environment Configuration

To start a new control development project, the simula-

tion environment needs to be configured. An EnergyPlus In-

put Data File (IDF) and a weather file are first selected and

parsed using the MLE+ front-end. For our example we use

the EMSWindowShadeControl.idf file, which is available as

an example in the EnergyPlus distribution and contains the de-

scription for our building.

2.2 I/O Variables Configuration

MLE+ provides a graphical front-end for specifying the

input-output variables to be exchanged between EnergyPlus

and Matlab for co-simulation. An input variable serves as

an input to EnergyPlus at each step of the co-simulation,

while output variables are those which can be repeatedly

read from EnergyPlus to monitor its internal state. For

our example, we specify Shading Deployment Status and

ShadeAngle Schedule as the inputs to EnergyPlus as these

are the variables that we will control using MLE+. The con-

troller will need to monitor the incident solar radiation and

angle at the West zone, therefore these are specified as out-

put variables. After a description file for a building has been

loaded, the MLE+ front-end displays all available input and

output variables pertaining to that building.

In MLE+, an alias can be specified for each of the variables

(Fig. 3(b)). The alias allows a user to reference a variable with

a more intuitive name and avoid the intricate names speci-

fied by EnergyPlus. For instance, the EnergyPlus variable

Zn001_Wall001_Win001_Shading_Deployment_Status

can be assigned a more intuitive name as ShadeStatus. The

alias of a variable can be used later during the controller

design and to map to addresses of physical devices in a

BACnet network.

2.3 Control Design

In this step, a controller for the window blinds is designed

and implemented. The MLE+ front-end for control design

generates a Matlab code template for specifying the control

algorithm based on the input-output variables defined in the

previous step. The I/O variables specified by the user are re-

ferred to by their aliases throughout the control file as shown

in Fig 3(c). In the code snippet shown in Fig 3(c) the value of

the incident solar radiation is compared against the threshold

(100 W/m

2

) to determine if the shades will be deployed.

2.4 Simulation and Assessment

Once a preliminary control design has been agreed upon,

we can run the simulation or step through it using Matlab de-

bugging environment. MLE+ successfully decouples the sim-

ulation engine and the control strategy. This way we can work

on tuning the control scheme from Matlab, running multiple

simulations without the need of modifying the EnergyPlus file.

After the co-simulation finishes, MLE+ extracts and parses all

output variables generated by EnergyPlus making them avail-

able at the front-end (Fig 3(d)). The output variables can be

plotted for a quick view and can be easily saved to the Matlab

workspace for further analysis.

Fig 3(e) shows the results of the window shade controller

for our example. Notice how the shades are deployed when-

ever the incident solar radiation exceeds a certain threshold

thereby limiting the transmitted solar radiation. Although the

example presented in this section is simple, it demonstrates

how MLE+ can expedite the control design by allowing the

user to quickly make changes to the controller, then simulate

and assess the results.

3 MLE+ Architecture

The structure of MLE+, shown in Fig 1, consists of MLE+

Core components and the MLE+ Workflow. The MLE+ Core

components provide interfaces to building simulation tools and

building devices. The MLE+ workflow is a sequence of oper-

ations which utilize the core components to efficiently design,

(a) EnergyPlus window shading control model

(b) Assigning aliases to variable names

mcode.sty Demo

July 31, 2012

1 if Zone West Solar > 100

2 % DEPLOYED WHEN SOLAR RADIATION EXCEEDS THRESHOLD

3 ShadeStatus = userdata.Shade Status Exterior Blind On;

4 ShadeAngle = IncidentAngle;

5 else

6 % SHADES NOT DEPLOYED

7 ShadeStatus = userdata.Shade Status Off;

8 ShadeAngle = IncidentAngle;

9 end

10 % FEEDBACK

11 eplus in curr.ShadeStatus = ShadeStatus;

12 eplus in curr.ShadeAngle = ShadeAngle;

13 end

1

(c) Matlab code snippet of the shading controller (notice alias variables)

(d) viewing plots of EnergyPlus outputs

1d 2d 3d 4d 5d

0

1,000

2,000

3,000

Time

Radiation kW

Window Incident Radiation (W)

Window Transmitted Radiation (W)

Shade ON

(e) Window shade controller results

Figure 3. MLE+ workflow example

simulate and evaluate a controller for a given plant model or

building automation platform.

3.1 MLE+ Core

The MLE+ core handles the interfaces for data-exchange

with building simulation tools and communication with build-

ing management systems. It uses a Java socket library for

co-simulation with EnergyPlus and a BACnet stack library for

communicating with BACnet devices. Currently, the interface

supports communication with EnergyPlus and BACnet but in

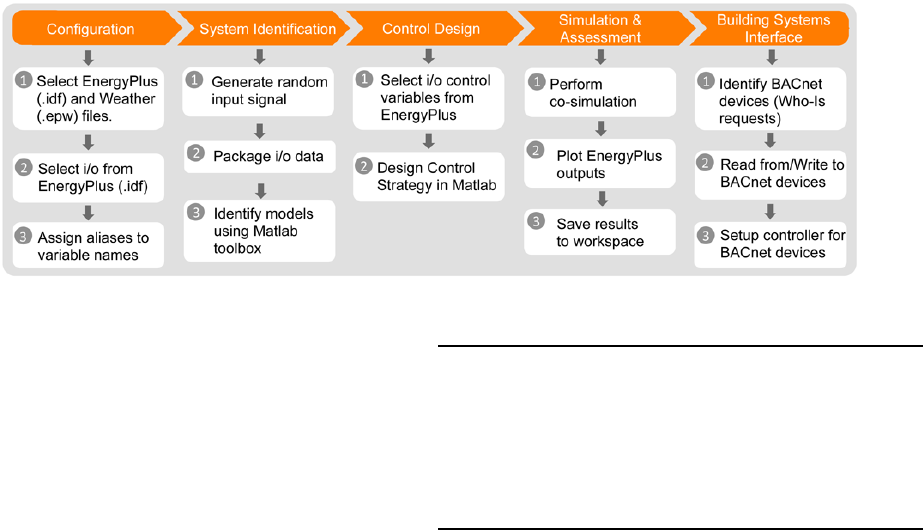

Figure 4. MLE+ control development workflow.

future it will be extended to support other systems as well,

for example the Radiance lighting simulation software [9] and

OpenADR [10]. The MLE+ Core also provides an Application

Programming Interface (API) which contains a set of low-level

Matlab functions and classes responsible for all other compo-

nents the MLE+.

3.2 MLE+ Utilities

MLE+ utilities are built on top of the API to facilitate the

development of building energy simulation, control, analysis

and optimization. Some examples of MLE+ utilities are:

• A function for parsing and extracting parameters from

EnergyPlus building description files.

• An editor that automates the configuration and mapping

of external variables for EnergyPlus.

• A simulation result viewer that can load, plot, and export

simulation results from EnergyPlus to Matlab.

• A drawing viewer that exports the building geometry

from EnergyPlus and display it in Matlab.

3.3 MLE+ Simulink blocks

MLE+ provides a Simulink blockset library for co-

simulation between Simulink and other building simulation

software. The Simulink blocks are essentially a wrapper of the

MLE+ Core for Simulink. This facilitates model based design

for building energy control.

3.4 MLE+ Workflow

The core components of MLE+ enable efficient workflow

for common tasks, such as developing advanced building con-

trols and optimizing building automation parameters. The de-

velopment workflow, as shown in Fig 4, facilitates a complete

design cycle from model identification of an EnergyPlus build-

ing model, to designing an energy-efficient controller, to fi-

nally deploying the control algorithm in real buildings through

BACnet.

4 Case Study 1:

Energy-Efficient Controller Design

Radiant heating systems serve as an alternative to the con-

ventional forced-air heating, ventilation and air conditioning

(HVAC) systems for thermal conditioning of buildings. A ra-

diant floor heating system works by warming up the floor sur-

face which then slowly radiates heat upward into the living

space. In [11] an algorithm for peak power reduction of ra-

diant heating systems is presented and is implemented using

EnergyPlus. For this case study, we will use the same example

as in [11]. The objective here is not to develop new energy-

efficient control algorithms for radiant heating systems, but to

Table 1. List of parameters

R

z

i

, j

thermal resistance of the j

th

layer in zone z

i

C

z

i

, j

thermal capacitance of the j

th

layer in zone z

i

C

z

i

thermal capacity of zone z

i

K

z

i

thermal conductance between the zone and outside air

K

i j

thermal conductance between the zone i and zone j, i 6= j

T

a

outside ambient air temperature

Q

hg,z

i

internal heat gain due to occupants etc.

Q

sol,z

i

heat gain due to solar radiation etc.

Q

rad,z

i

heat gain from radiant floor system etc.

show the potential and ease of use of MLE+ in developing and

evaluating such algorithms.

4.1 Simulation set-up

A single floor, L-shaped building divided into

three interior zones is used as the plant model. The

RadLoTempElecTermReheat.idf description file provided

with EnergyPlus examples was used for this case study. An

electric low temperature radiant system is used for heating

the floor of each zone, with power ratings of 12kW, 8kW

and 8kW for the North, West and East zones respectively.

Temperatures in each zone were required to be kept between

l = 22

◦

C and h = 24

◦

C. The ambient air temperature profile

was of Chicago, IL, USA. We will compare two different

scenarios. In the first one, we used MLE+ to implement a

control strategy to switch the electric radiant system in each

zone ON or OFF (binary) in an energy efficient manner while

ensuring that thermal comfort inside each zone is maintained.

The second scenario considers a continuous control where

the controlled variable takes any number between 0 and

the maximum output power of the radiant system. For this

case, we will use MPC to minimize the total energy usage

throughout the day.

4.2 Model Identification

The internal thermal model of the EnergyPlus building is

not accessible from outside EnergyPlus, therefore the first step

was to identify a linear state-space model for the building using

the MLE+ system identification workflow.

4.2.1 System Model

The dynamics of each zone is modeled using a RC network

“lumped-parameter” model as shown in Fig 5. The list of all

parameters in the model is given in Table 1. The law of conser-

vation of energy gives us the following heat balance equation

T

z1,0

Ah

g

1

T

z1,1

T

z1,i

T

z1,m1

source,z1

C

z1,1

C

z1,1

R

z1,1

C

z1,i

R

z1,i

Floor Surface

T

z1

Ah

a

1

C

z1

K

12

Ah

g

1

T

z2,1

T

z2,i

T

z2,m1

source,z2

C

z2,1

C

z2,1

R

z2,1

C

z2,i

R

z2,i

T

z2

Ah

a

1

C

z2

T

z2,0

Floor Surface

Floor Layers

T

a

T

a

Q

rad,z1

Q

rad,z2

K

z1

K

z2

Ground

{Q

hg,z1

;Q

sol,z1

}

{Q

hg,z2

;Q

sol,z2

}

Figure 5. Thermal RC network model for an electric radi-

ant floor heating system

for zone z

i

:

C

z

i

dT

z

i

(t)

dt

= K

zi

(T

a

(t)−T

z

i

(t))+

∑

j6=i

K

i j

T

z

j

(t)−T

z

i

(t)

+ Q

hg,z

i

(t)+Q

sol,z

i

(t)+Q

rad,z

i

(t) (1)

where T

z

i

is the temperature of zone z

i

. The control input to

each zone z

i

is the state of the electric radiant system. This

control input is denoted by u

i

∈ [0, 1] where u

i

= 0 corresponds

to the OFF state with no power consumption and u

i

= 1 the

ON state with maximum power consumption and any interme-

diate value of u denotes the fraction of maximum power being

consumed. Differential equations for all the zones can be com-

bined to give the following state space model for the building:

˙x(t) = A

i

x(t) + Bu(t) + Dw(t) (2)

Where the state x(t) consists of node temperatures (3 nodes

per zone), control input u(t) to the radiant heater, and w(t) are

disturbances to the system (solar heat gain, occupants etc.).

4.2.2 System Identification with MLE+

System identification involves using time-domain and

frequency-domain input-output data to identify continuous-

time and discrete-time transfer functions, process models, and

state-space models. The MLE+ system identification work-

flow helps in (i) Generating input-output data from EnergyPlus

and (ii) Structuring input-output data in a format ready to be

used by Matlab’s System Identification toolbox.

The MLE+ system identification front-end can generate sig-

nals with distinct characteristics for identification purposes.

Fig 6(a) shows how the control inputs to EnergyPlus are ini-

tialized as random binary signals (rbs) to carry out controlled

simulations in EnergyPlus. The MLE+ system identification

module streamlines the process of packaging the simulated I/O

variables into a Matlab object. This object can be imported

into the Matlab’s System Identification Toolbox to identify the

parameters of the radiant system (Fig 6(b)). This particular ex-

ample demonstrates how MLE+ allows a seamless integration

with Matlab Toolboxes and built-in functions.

4.3 Energy-Efficient Controller Design

In the ON/OFF case, uncoordinated operation among elec-

tric radiant heating systems across multiple zones can cause

peaks in the electricity consumption of the building. This oc-

curs when all electric radiant heating systems are simultane-

ously consuming electricity i.e., the electric radiant system in

each zone is ON at the same time. Our goal is to evaluate

different control methods to reduce the peak power consump-

tion while ensuring that the temperature inside each zone stays

within the comfort range. Through MLE+, one can specify any

valid control method for a plant, since it provides a template

control file as starting point. We implemented two strategies

for this scenario in MLE+:

1. On-Off uncoordinated control: To observe uncoordi-

nated control among the zones, we implemented a base-

line controller in MLE+ to regulate the temperature of

each zone like a two-position thermostat.

2. Green Scheduling for peak power minimization: Us-

ing the identified state-space model, we implemented the

Green Scheduling algorithm for peak power reduction

of radiant heating systems in MLE+. Green Schedul-

ing [11], is a simple and lightweight approach for coordi-

nating energy consuming control systems to reduce their

peak power consumption.

In the second case, we implemented two continuous control

schemes to maintain the zone temperatures within the same

comfort range.

1. Proportional control: This simple control feedback is

purely reactive as it only considers the current zone’s

temperature values. The controlled variable, the electric

power of the radiant system, is proportional to the differ-

ence of the setpoint and the zone’s temperature.

2. Model Predictive Control: Using MLE+, we imple-

mented a (relatively sophisticated) model based predic-

tive controller for total power minimization. We used the

identified linear state-space model with Matlab’s MPC

toolbox to compute the optimal power level of the elec-

tric radiant heater in each zone. We then fed these power

levels as control inputs to EnergyPlus via MLE+ at each

simulation step.

By designing multiple controllers in MLE+ for the same

plant in EnergyPlus, we can make a fair comparison between

the performance of the control algorithms for each scenario.

(a) Generating input-output data for system identification

(b) Packaging input-output data System Identification

Figure 6. System Identification using MLE+

8a 9a 10a 11a 12p 1p 2p 3p 4p 5p 6p

10

20

30

Time of day (h)

Power (kW)

Green Scheduling Uncoordinated

(a) Green Scheduling vs. Uncoordinate Power Consumption

8a 9a 10a 11a 12p 1p 2p 3p 4p 5p 6p

10

20

30

Time of day (h)

Power (kW)

MPC Proportional

(b) MPC vs. Proportional Power Consumption

Figure 7. Case Study 1 Power Profile

The power profile of the four control methods are shown in

Fig 7(a) and 7(b) while total power consumption and peak

power are presented in Table 2. In both cases, zone tempera-

tures were kept in the desired range between 22

◦

C and 24

◦

C.

We observed that the curve of electricity demand for the unco-

ordinated control strategy had several high peaks while it was

smoother and flatter for the green scheduling strategy. In total,

green scheduling helped save 8% in electricity consumption

and reduce peak demand by 42.9%. Also, there is a decrease in

the total energy consumption since the periodic schedule tends

to operate at a lower mean temperature than the uncoordinated

control.

For the continuous control case, the MPC simulation did

not achieve a smaller total power during the day. This outcome

can be attributed to the fidelity of the model. The MPC imple-

mentation requires a more rigorous model and higher accuracy

in predicted parameters. These improvements are definitely

achievable with MLE+. We did not pursue this task, as our

intention was not focused on the development of a novel feed-

back control, but on the potential of MLE+ to achieve this. In

the control design iteration process, MLE+ proves extremely

useful as it allows access to the complete debugging environ-

ment within Matlab. This translates into considerable time and

effort savings.

5 Case Study 2:

BACnet interface with test-bed

Controllers implemented in MLE+ can be used for control-

ling real building devices through BACnet. BACnet [12] was

designed to allow communication of building automation and

control systems for applications such HVAC, lighting control,

access control, fire detection systems and their associated de-

vices. The BACnet protocol defines the format and delivery of

messages these devices exchange.

ON-OFF Control Continuous Control

Uncoordinated GS (%saved) Proportional MPC (%saved)

Consumption (kW h) 93.2 85.7 (8.0%) 84.5 99.7(−2.8%)

Peak demand (kW) 28.0 16.0 (42.9%) 17.4 17.9 (−15.3%)

Table 2. Consumption and peak demand in case study 1

5.1 The BACnet standard

BACnet provides a way of representing any device as long

as the device has certain functions specified in the BACnet

standard. The standardized BACnet model of a device rep-

resents these functions as collections of related information

called objects each of which has a set of properties that fur-

ther describe it. Each analog input of a device, for instance,

is represented by a BACnet Analog Input object which has a

set of standard properties like Present Value, Sensor Type,

Location, Alarm Limits, and so on. Some of these proper-

ties are required while others are optional. One of the object’s

most important properties is its identifier, a numerical name

that allows BACnet to unambiguously access it.

An example of a BACnet device is a temperature sensor.

It is represented as a BACnet Analog Input object with a

Present Value property which is read as the sensor signal.

5.2 MLE+ BACnet interface

The BACnet interface in MLE+ (Fig5.2) is built upon the

BACnet Stack [13] , which is an open source BACnet protocol

stack for embedded systems. For the case study, MLE+ is in-

terfaced with a test-bed that simulates both the dynamics of a

building and the behavior of BACnet devices.

The test-bed consists of a building with four zones, as

shown in Fig 5. Each zone has independent heating and cool-

ing elements which can be controlled to regulate its tempera-

ture. Sensor nodes monitor the temperature and energy levels

in different zones of the building. An energy dashboard, shown

in Fig.8(b), displays the current temperature of each zone and

the power consumption of the building. The test-bed is iso-

lated from the surroundings by an outer box, which acts as the

outside environment for the building. Fig. 8(b) shows that the

temperature dynamics of each zone in the test-bed is similar to

the dynamics of a real building.

Each zone of the building test-bed acts as a single BACnet

device with two objects: (i) An Analog Input object to read

the zone temperature, and (ii) An Analog Output object to

control the status of the heating element in the zone.

BACnet is based on a “client-server” model, therefore

BACnet messages are often called service requests. MLE+ be-

haves as a client and sends service requests to a server, which

is usually a BACnet Device. The device/server then performs

the service and reports the result to MLE+. A common service

request is the Who-Is broadcast message, which help the client

to identify devices on the BACnet network. MLE+ can gener-

ate Who-Is service requests to identify the BACnet devices in

the building (Fig9(a)). Each device replies back with an I-am

message containing its device ID. MLE+ can identify the list

of all available BACnet devices or devices with IDs that fall in

a specific range. MLE+ can also query a specific device if its

ID is known. This is useful for checking whether the device is

still operational.

Based on the functionality of a device, MLE+ can read

and write properties to it. Fig 9(b) depicts how the Present

Value of the Analog Output of zone 1 can be set to 10

by sending a BACnet WriteProperty request. The Analog

Output object controls the heating element of the zone and a

value of 10 that the heating element will operate at 10% of its

maximum operating power. Similarly, as shown in Fig 9(c),

using the Read Property request, the temperature value of a

zone can be read. The temperature sensor is represented as an

Analog Input object.

(a) Test bed with 4 zones (b) Energy dashboard showing zone temperatures and power

Figure 8. Building test-bed with BACnet connectivity to MLE+

Since MLE+ allows designing controllers in Matlab, a sim-

ple feedback controller can be specified for each zone. The

controller periodically reads the temperature from each zone

and switches the heating elements ON and OFF such that the

temperature inside each zone stays within the upper and lower

thresholds at all times.

This is a simple example but it paves the way for using

MLE+ for modern energy-efficient control methods such as

MPC, as described in Section 4). Fig 8(b) shows the perfor-

mance of two controllers implemented for the test-bed with

MLE+. Controller 1 controls each zone independently of the

other zones. This uncoordinated behavior among the zones re-

sults in peaks in the total power consumption of the building.

Controller 2 coordinates the zone controls such that the peak

power consumption for the building is minimized.

6 Related Work

The building automation communities have explored the

application of advanced control methods for buildings [14, 15,

16, 17, 18] using building energy simulation tools. In [14], the

performance of a real building is analyzed and optimized us-

(a) BACnet Who-IS request in MLE+

(b) BACnet Write Property in MLE+

(c) BACnet Read Property in MLE+

Figure 9. MLE+ BACnet Interface

ing EnergyPlus models. In [18], a Siemens Apogee controller

is used for demand response control and predictive modeling

of a campus building using EnergyPlus. [14, 15, 17] present

occupancy driven approaches for energy efficient building con-

trol but the proposed control methods cannot be implemented

in EnergyPlus since EnergyPlus uses fixed schedules for occu-

pants. In each of these cases, MLE+ can be used for perfor-

mance evaluation of the proposed control methods with Ener-

gyPlus.

HAMlab [19] provides a collection of tools suitable for sim-

ulation with Matlab/Simulink but is mainly suited for mod-

eling the heat and moisture flows in a building. THER-

MOSYS [20] is another Matlab toolbox for analyzing the be-

havior of air-conditioning and refrigeration systems. It con-

tains dynamic models of the basic components used in com-

pression cycles but it cannot be used for whole building simu-

lation. TRNSYS can as well interface with Matlab by running

it as a process for simulating a design component. However, it

does not provide whole-building simulation and does not ex-

ploit Matlab’s environment. Specifically, it cannot use Mat-

lab’s built-in debugging capabilities.

A popular tool for building energy co-simulation is the

Building Controls Virtual Test Bed (BCVTB) [21], but it has a

few limitations which are discussed next.

6.1 Comparison with BCVTB

BCVTB is a software environment, based on Ptolemy II,

for coupling different simulation programs [22, 23]. It can link

different simulation programs for co-simulation, including En-

ergyPlus and Matlab. The co-simulation feature in EnergyPlus

was originally developed for BCVTB and can be used by any

program to perform co-simulation with EnergyPlus. MLE+ is

an example of such a program.

Although Matlab can be coupled with EnergyPlus via

BCVTB, its full functionality cannot be used because Mat-

lab is only called by BCVTB as an executable client. There-

fore, interactive execution and debugging of Matlab code is

not possible. Furthermore, if the Matlab code or the Simulink

model has an error, it is much more difficult to find and fix

it with BCVTB than with MLE+, which runs in the standard

Matlab environment. For users who mostly work with Mat-

lab/Simulink and have never used Ptolemy, learning a new en-

vironment as Ptolemy is time-consuming.

These limitations of BCVTB are echoed in the case study

presented in [24]. In the study, the authors acknowledged that

BCVTB requires considerable know-how and effort in order to

set up and operate the co-simulations. They also state how de-

bugging became more difficult for them as adding breakpoints

in Matlab code disrupted the co-simulations. They also experi-

enced an increase in the simulation times when using BCVTB.

MLE+ has some distinct advantages over BCVTB:

1. It takes full advantage of the Matlab/Simulink environ-

ment, including interactive simulation, code debugging,

code generation, and all available toolboxes. In other

words, it integrates better with Matlab/Simulink.

2. It is easier to extend MLE+, using Matlab programming,

for specialized applications and functions.

3. It is more familiar to users who mainly use Mat-

lab/Simulink, i.e. control engineers.

7 Use cases

MLE+ has been successfully used by both industry and

academia ( [25, 26, 27, 18]). In [25], Siemens implemented an

MPC-based Energy Management Controller (EMC) in Matlab

that exchanged data with EnergyPlus via MLE+. The authors

clearly assert in their work how they were able to take full

advantage of the Matlab toolboxes and MLE+ to achieve this

co-simulation. In [18], an intelligent automated demand re-

sponse building management system using EnergyPlus is pre-

sented. According to the report the team explored the utiliza-

tion of BCVTB but faced simulations problems caused due to

communication between EnergyPlus and Matlab. They then

switched to MLE+ for developing the demand response strate-

gies. The authors state that MLE+ is a much more reliable

way to synchronize the simulation between Matlab and Ener-

gyPlus. Another MPC implementation for EnergyPlus using

MLE+ is presented in [27] .

8 Discussion

While building simulation software tools can carry out ac-

curate and realistic building simulations they only provide very

basic control methods. On the other hand, control engineers

and researchers have explored advanced control strategies for

energy-efficient operation of a building, but more often than

not, such methods are based on simplified physical models in-

stead. MLE+ is intended to be used as a tool for building en-

ergy research and development by researchers who are familiar

with Matlab and want to use realistic building simulation capa-

bility of building energy simulation software like EnergyPlus.

Being a Matlab toolbox, MLE+ gives the user complete

access to all the toolboxes in Matlab and its computational

power. The ability to pause the co-simulation with EnergyPlus

and step through the code for debugging saves precious devel-

opment and testing time. This helps control engineers to rec-

ognize problems, eliminate errors and take informed decisions

early on in the design stage leading to fewer iterations in the

development cycle. This feature is not available in tools like

BCVTB. Workflows in MLE+ make it very easy to manage

tasks like model identification, control design and optimiza-

tion, post simulation analysis and integration between software

applications and building equipment. MLE+ can also be used

for tuning building parameters for both building simulation

models inside EnergyPlus and for real building equipment.

Our current effort involves extending the tool to work with

other building energy simulation tools like Radiance and Ope-

nADR and optimization and modeling tools such as BLOM

[28]. Our future work includes using MLE+ for synthesizing

a control strategy to control the indoor illumination levels and

HVAC system based on predicted and real time solar incident

radiation measurements in real buildings.

9 References

[1] D.B. Crawley, L.K. Lawrie, C.O. Pedersen, and F.C. Winkelmann. En-

ergy plus: energy simulation program. ASHRAE journal, 42(4), 2000.

[2] SA Klein and University of Wisconsin-Madison Solar Energy Labora-

tory. TRNSYS: A transient simulation program. Eng. Experiment Sta-

tion, 1976.

[3] P. Strachan. Esp-r: Summary of validation studies. Energy Systems

Research Unit, University of Strathclyde, Scotland, UK, 2000.

[4] equest: the quick energy simulation tool. http://doe2.com/equest/.

[5] F. C. Winkelmann et. al. DOE-2 Supplement: Version 2.1 e. Technical

report, Lawrence Berkeley Lab., CA (United States); Hirsch (James J.)

and Associates, Camarillo, CA (United States), 1993.

[6] A. Tindale. Designbuilder software. Stroud, Gloucestershire, Design-

Builder Software Ltd, 2005.

[7] EnergyPlus External Interface(s) Application Guide, May 2012.

[8] E.F. Camacho and C. Bordons. Model Predictive Control. Springer,

2004.

[9] G.J. Ward. The RADIANCE lighting simulation and rendering system.

In Conf. Computer graphics & interactive techniques. ACM, 1994.

[10] M.A. Piette, G. Ghatikar, S. Kiliccote, E. Koch, D. Hennage, P. Palensky,

and C. McParland. Open automated demand response communications

specification (version 1.0). Technical report, LBNL, 2009.

[11] Truong X. Nghiem, M. Behl, Rahul Mangharam, and George J. Pappas.

Green scheduling for radiant systems in buildings. In Conference on

Decision and Control, Hawaii, USA, Dec. 2012.

[12] ASHRAE. Standard 135-1995: BACnet, Data Communication Protocol

for Building Automation and Control Networks. ASHRAE, 1995.

[13] Steve Karg. Bacnet stack: An open source bacnet protocol stack for

embedded systems. http://bacnet.sourceforge.net/.

[14] S. Narayanan, J. S. Apte, P. Haves, M. D. Sohn, and J. Elliott. Systems

approach to energy efficient building operation. ACEEE Summer Study

on Energy Efficiency in Buildings, 2010.

[15] Y. Agarwal et. al. Occupancy-driven energy management for smart

building automation. In BuildSys, 2010.

[16] V. L. Erickson and A. E. Cerpa. Occupancy based demand response hvac

control strategy. In BuildSys, pages 7–12, 2010.

[17] C. Liao, Y. Lin, and P. Barooah. Agent-based and graphical modelling of

building occupancy. Journal of Building Performance Simulation, 2012.

[18] D. Culler, P.K. Wright, Y. Lu, and M Piette. A distributed intelligent

automated demand response building management system. Technical

report, University of California, Berkeley, 2011.

[19] AWM van Schijndel and JLM Hensen. Integrated heat, air and mois-

ture modeling toolkit in matlab. In Proc. of 9th International IBPSA

Conference, 2005.

[20] B.P. Rasmussen. Thermosys toolbox user’s manual, 2002.

[21] Michael Wetter. Co-simulation of building energy and control systems

with the building controls virtual test bed. Journal of Building Perfor-

mance Simulation, 4(3):185–203, 2011.

[22] M. Wetter and P. Haves. A modular building controls virtual test bed for

the integrations of heterogeneous systems. SimBuild, 2008.

[23] Xiufeng Pang, Michael Wetter, Prajesh Bhattacharya, and Philip Haves.

A framework for simulation-based real-time whole building perfor-

mance assessment. Building and Environment, 54(0):100 – 108, 2012.

[24] C. Sagerschnig, D. Gyalistras, A. Seerig, S. Pr

´

ıvara, J. Cigler, and

Z. Vana. Co-simulation for building controller development: The case

study of a modern office building. In Proceedings of CISBAT, 2011.

[25] K. Ji et. al. Prognostics enabled resilient control for model-based build-

ing automation systems. In 12th Building Simulation Conference, 2011.

[26] I. Leobner, K. Ponweiser, G. Neugschwandtner, and W. Kastner. Energy

efficient production - a holistic modeling approach. In Sustainable Tech-

nologies (WCST), 2011 World Congress on, pages 62 –67, nov. 2011.

[27] F. Sakellariou. Model predictive control for thermally activated building

systems. Masters Thesis, 2011.

[28] BLOM: The Berkeley Library for Optimization Modeling and Nonlinear

Model Predictive Control. http://www.mpc.berkeley.edu/people/

sergey-vichik/file/BLOM_paper.pdf.