Facilities Management

5/16/2024

Design GUIDELINES

Design Guidelines Facilities Management

i

Contents

PREFACE vii

Change Log viii

Definitions xi

Procurement & Contracting ........................................................................................................... 00-1

00 10 00 Solicitation/Bid Advertisement .................................................................................................. 00-1

00 21 00 Instructions to Bidders ............................................................................................................... 00-1

00 31 31 Geophysical Data ....................................................................................................................... 00-1

00 45 13 Bidder Qualifications .................................................................................................................. 00-1

00 72 00 General Conditions of the Contract ............................................................................................. 00-1

General Requirements ................................................................................................................... 01-1

01 00 00 General Project/Design Requirements ........................................................................................ 01-1

01 14 00 Work Restrictions (Site Access, Occupant Coordination, Site Use)................................................ 01-4

01 20 00 Change Order Procedures........................................................................................................... 01-4

01 31 00 Coordination .............................................................................................................................. 01-4

01 33 00 Submittals ................................................................................................................................. 01-5

01 35 00 Special Project Procedures ......................................................................................................... 01-5

01 51 00 Temporary Utilities .................................................................................................................... 01-6

01 52 00 Construction Facilities ................................................................................................................ 01-6

01 55 00 Vehicular Access and Parking ..................................................................................................... 01-7

01 56 00 Temporary Barriers and Enclosures ............................................................................................ 01-7

01 56 39 Temporary Tree and Plant Protection ......................................................................................... 01-8

01 57 00 Temporary Controls ................................................................................................................... 01-8

01 60 00 Product Requirements ............................................................................................................... 01-8

01 73 00 Execution ................................................................................................................................... 01-9

01 74 00 Cleaning and Waste Management .............................................................................................. 01-9

01 77 00 Closeout Procedures .................................................................................................................. 01-9

01 78 00 Closeout Submittals ................................................................................................................... 01-9

01 78 23 Operation and Maintenance Data ............................................................................................ 01-10

01 78 36 Warranties............................................................................................................................... 01-10

01 78 44 Extra Stock Materials ............................................................................................................... 01-11

01 79 00 Demonstration and Training ..................................................................................................... 01-11

01 80 00 Performance Requirements ...................................................................................................... 01-11

01 81 00 Facility Performance Requirements (Alternate) ........................................................................ 01-11

Site Construction ........................................................................................................................... 02-1

02 30 00 Subsurface Investigation ............................................................................................................ 02-1

02 40 00 Demolition and Structure Moving ............................................................................................... 02-1

Concrete ....................................................................................................................................... 03-1

Design Guidelines Facilities Management

ii

03 05 00 Common Work Results for Concrete ........................................................................................... 03-1

03 10 00 Concrete Forming ...................................................................................................................... 03-1

03 15 00 Concrete Accessories ................................................................................................................. 03-1

03 20 00 Concrete Reinforcing .................................................................................................................. 03-1

03 30 00 Cast-In-Place Concrete ............................................................................................................... 03-1

03 35 00 Concrete Finishing...................................................................................................................... 03-2

03 35 11 Concrete Floor Finishes .............................................................................................................. 03-2

03 39 00 Concrete Curing ......................................................................................................................... 03-5

Masonry........................................................................................................................................ 04-1

04 05 00 Common Work for Masonry ....................................................................................................... 04-1

Metals .......................................................................................................................................... 05-1

05 40 00 Cold Formed Metal Framing ....................................................................................................... 05-1

05 50 00 Metal Fabrications ..................................................................................................................... 05-1

Wood, Plastics, and Composites ..................................................................................................... 06-1

06 10 00 Rough Carpentry ........................................................................................................................ 06-1

06 41 00 Architectural Wood Casework .................................................................................................... 06-1

Thermal & Moisture Protection ..................................................................................................... 07-1

07 05 00 Common Work Results for Thermal & Moisture Protection ......................................................... 07-1

07 10 00 Dampproofing and Waterproofing.............................................................................................. 07-1

07 21 00 Thermal Insulation ..................................................................................................................... 07-1

07 26 00 Vapor Retarders ......................................................................................................................... 07-1

07 50 00 Membrane Roofing .................................................................................................................... 07-1

07 60 00 Flashing and Sheet Metal ........................................................................................................... 07-2

07 70 00 Roof and Wall Specialties and Accessories .................................................................................. 07-2

07 90 00 Joint Protection ......................................................................................................................... 07-2

Openings (Doors & Windows) ........................................................................................................ 08-1

08 05 00 Common Work Results for Openings .......................................................................................... 08-1

08 10 00 Doors and Frames ...................................................................................................................... 08-1

08 11 13 Hollow Metal Doors and Frames................................................................................................. 08-1

08 11 16 Aluminum Doors and Frames ..................................................................................................... 08-3

08 31 00 Access Doors and Panels ............................................................................................................ 08-4

08 50 00 Windows ................................................................................................................................... 08-4

08 70 00 Hardware .................................................................................................................................. 08-5

Finishes ......................................................................................................................................... 09-1

09 05 00 Common Work Results for Finishes ............................................................................................ 09-1

09 20 00 Plaster and Gypsum Board ......................................................................................................... 09-1

09 51 00 Acoustical Ceilings ..................................................................................................................... 09-1

09 60 00 Flooring ..................................................................................................................................... 09-1

Design Guidelines Facilities Management

iii

09 68 00 Carpet ....................................................................................................................................... 09-1

09 70 00 Wall Finishes .............................................................................................................................. 09-2

09 90 00 Painting and Coating .................................................................................................................. 09-2

Specialties ..................................................................................................................................... 10-1

10 11 00 Visual Display Surfaces ............................................................................................................... 10-1

10 13 00 Directories ................................................................................................................................. 10-1

10 14 00 Signage ...................................................................................................................................... 10-1

10 28 00 Toilet and Bath Accessories ........................................................................................................ 10-1

Equipment .................................................................................................................................... 11-1

11 21 23 Vending Equipment ................................................................................................................... 11-1

11 52 13 Projection Screens ..................................................................................................................... 11-1

Furnishings .................................................................................................................................... 12-1

12 20 00 Window Treatment .................................................................................................................... 12-1

12 30 00 Manufactured Casework ............................................................................................................ 12-1

12 31 00 Manufactured Metal Casework .................................................................................................. 12-1

12 36 00 Countertops ............................................................................................................................... 12-9

12 50 00 Furniture ................................................................................................................................... 12-9

12 60 00 Multiple Seating ........................................................................................................................ 12-9

12 93 13 Bicycle Racks ............................................................................................................................ 12-10

Special Construction ...................................................................................................................... 13-1

Conveying Systems ........................................................................................................................ 14-1

14 20 00 Elevators ................................................................................................................................... 14-1

14 40 00 Lifts ........................................................................................................................................... 14-1

Reserved ....................................................................................................................................... 15-1

Reserved ....................................................................................................................................... 16-1

Reserved ....................................................................................................................................... 17-1

Reserved ....................................................................................................................................... 18-1

Reserved ....................................................................................................................................... 19-1

Reserved ....................................................................................................................................... 20-1

Fire Suppression ............................................................................................................................ 21-1

21 05 00 Common Work Results for Fire Suppression ............................................................................... 21-1

21 10 00 Fire Protection System Impairment Procedure ............................................................................ 21-1

Plumbing ....................................................................................................................................... 22-1

22 05 00 Common Work Results for Plumbing .......................................................................................... 22-1

22 05 53 Identification for Plumbing Piping and Equipment ...................................................................... 22-1

22 07 00 Plumbing Insulation ................................................................................................................... 22-2

22 07 16 Plumbing Equipment Insulation .................................................................................................. 22-2

22 07 19 Plumbing Piping Insulation ......................................................................................................... 22-2

22 10 00 Plumbing Piping and Pumps ....................................................................................................... 22-4

22 14 00 Facility Storm Drainage .............................................................................................................. 22-5

Design Guidelines Facilities Management

iv

22 30 00 Plumbing Equipment .................................................................................................................. 22-5

22 40 00 Plumbing Fixtures ...................................................................................................................... 22-5

Heating, Ventilating, and Air Conditioning ...................................................................................... 23-1

23 05 00 Common Work Results for HVAC ................................................................................................ 23-1

23 07 00 HVAC Insulation ......................................................................................................................... 23-2

23 07 13 Duct Insulation .......................................................................................................................... 23-2

23 07 16 Equipment Insulation ................................................................................................................. 23-3

23 07 19 HVAC Piping Insulation ............................................................................................................... 23-4

23 09 00 Instrumentation and Control for HVAC ....................................................................................... 23-6

23 20 00 HVAC Piping and Pumps ............................................................................................................. 23-6

23 22 01 Underground Steam and Condensate Distribution System .......................................................... 23-7

23 22 02 Steam and Condensate Piping and Pumps within buildings ......................................................... 23-9

23 23 00 Refrigerant Piping .................................................................................................................... 23-10

23 30 00 HVAC Air Distribution ............................................................................................................... 23-10

23 40 00 HVAC Air Cleaning Devices ....................................................................................................... 23-10

23 25 00 HVAC Water Treatment ............................................................................................................ 23-11

23 60 00 Central Cooling Equipment ....................................................................................................... 23-11

23 81 26 VRV Air Conditioners ................................................................................................................ 23-11

Reserved ....................................................................................................................................... 24-1

Integrated Automation .................................................................................................................. 25-1

Electrical ....................................................................................................................................... 26-1

26 05 00 Common Work Results for Electrical ........................................................................................... 26-1

26 10 00 High-Voltage Electrical Distribution ............................................................................................ 26-2

26 20 00 Electrical Distribution ................................................................................................................. 26-2

26 32 00 Packaged Generator Assemblies ................................................................................................. 26-2

26 50 00 Lighting ..................................................................................................................................... 26-2

Communications ........................................................................................................................... 27-1

27 10 00 Structured Cabling ..................................................................................................................... 27-1

27 10 05 Telecommunications Cabling ...................................................................................................... 27-7

27 50 00 Distributed Communications and Monitoring Systems .............................................................. 27-17

Electronic Safety and Security ........................................................................................................ 28-1

28 10 00 Electronic Access Control and Intrusion Detection ...................................................................... 28-1

28 30 00 Electronic Detection and Alarm .................................................................................................. 28-1

Reserved ....................................................................................................................................... 29-1

Reserved ....................................................................................................................................... 30-1

Earthwork ..................................................................................................................................... 31-1

31 14 00 Earth Stripping and Stockpiling ................................................................................................... 31-1

31 22 00 Grading ..................................................................................................................................... 31-1

31 23 00 Excavation and Fill ..................................................................................................................... 31-1

Design Guidelines Facilities Management

v

Exterior Improvements .................................................................................................................. 32-1

32 05 00 Common Work Results for Exterior Improvements ..................................................................... 32-1

32 11 00 Base Courses .............................................................................................................................. 32-1

32 14 00 Unit Paving ................................................................................................................................ 32-1

32 32 00 Retaining Walls .......................................................................................................................... 32-1

32 80 00 Irrigation ................................................................................................................................... 32-1

32 90 00 Planting ..................................................................................................................................... 32-2

Utilities ......................................................................................................................................... 33-1

33 30 00 Sanitary Sewerage Utilities ......................................................................................................... 33-1

33 46 00 Storm Drainage Utilities ............................................................................................................. 33-1

Transportation .............................................................................................................................. 34-1

34 05 00 Common Work Results for Transportation .................................................................................. 34-1

Waterway and Marine Construction .............................................................................................. 35-1

Reserved ....................................................................................................................................... 36-1

Reserved ....................................................................................................................................... 37-1

Reserved ....................................................................................................................................... 38-1

Reserved ....................................................................................................................................... 39-1

Process Integration ........................................................................................................................ 40-1

Material Processing and Handling Equipment................................................................................. 41-1

Process Heating, Cooling, and Drying Equipment ............................................................................ 42-1

Process Gas & Liquid Handling, Purification, and Storage Equipment .............................................. 43-1

Pollution Control Equipment .......................................................................................................... 44-1

Industry-Specific Manufacturing Equipment ................................................................................... 45-1

Reserved ....................................................................................................................................... 46-1

Reserved ....................................................................................................................................... 47-1

Electrical Power Generation........................................................................................................... 48-1

Reserved ....................................................................................................................................... 49-1

Exhibit A. Advertisement for Bids (00 10 00) .................................................................................................. A-1

Exhibit B. Bidder Questionnaire (00 45 13) ..................................................................................................... B-1

Exhibit C. Maintenance and Operating Manuals, Specifications, and Record Document Submittal Checklist (01

78 00) C-1

Exhibit D. Contractor Five Year Roof Guarantees ............................................................................................ D-1

Exhibit E. NDUS Architects-Engineers Manual (AEM) ....................................................................................... E-1

Exhibit F. NDUS AEM – Compensation Guidelines for Architectural Services .................................................... F-1

Exhibit G. NDUS AEM – Owner-Architect Agreement Amendments ................................................................. G-1

Exhibit H. NDUS AEM – Guidelines for Preparation of Construction Contracts and Related Documents ............ H-1

Exhibit I. NDUS AEM – Performance-Payment Bond (00 61 00) ........................................................................ I-1

Exhibit J. NDUS AEM – Insurance and Safety Requirements ............................................................................ J-1

Exhibit K. NDUS AEM – Agreement for Storing Materials Off-Site ....................................................................K-1

Exhibit L. NDUS AEM – Owner-Architect Agreement Amendments to AIA Document B141/CMA: Standard

Form of Agreement Between Owner and Architect Where the Construction Manager Is Not A

Constructor-Construction Manager-Advisor Edition ......................................................................... L-1

Exhibit M. NDUS AEM – Owner-Construction Manager Agreement Amendments ........................................... M-1

Design Guidelines Facilities Management

vi

Exhibit N. Americans With Disabilities Act Accessibility Guidelines Conformance Statement ........................... N-1

Exhibit O. Contractor Certification of Non-Asbestos and Non-Lead Materials .................................................. O-1

Exhibit P. NDSU Telecommunications Systems Construction Practices, Standards, and Procedures................... P-1

Design Guidelines Facilities Management

vii

PREFACE

These Design Guidelines, presented in forty-one divisions and sixteen exhibits, have been prepared to assist Architects and

Engineers who have been commissioned to design projects for the University by setting guidelines which are in the best interest

of the University. Throughout these Guidelines, the term “Architect”, “Engineer”, or “Consultant” is to be interchangeable with

the applicable discipline required on the project. These Guidelines, which have been developed over a period of years, will assist

all parties to eliminate problems that have developed from the use of substandard products and applications.

These Design Guidelines also affiliate with the North Dakota University System (NDUS) State Board of Higher Education (SBHE)

Policy Manual Section 900: Facilities. The NDUS Architect’s Manual (NDUS AEM) is included as Exhibits E through M of these

Guidelines. We feel this data can be useful and advantageous to the project, Architect/Engineer/Consultant, and the institution.

All the information contained in this folder is available in electronic format for Consultants use. Where there is a conflict between

the sections of these Design Guidelines and the NDUS AEM, the information of the Design Guidelines shall be followed.

Design Guidelines Contributors

Michael Ellingson Director of Facilities Management

Brent DeKrey Associate Director of Construction and Maintenance

Pete Zimmerman Associate Director of Facilities Operations

Christopher Hamre Maintenance & Project Coordinator

Justin Miller Project Manager

Eli Pederson Project Manager

Tracy Brown Drafting Technician

Eric Willis Heating Plant Manager

Chris Schroeder Carpenter Supervisor

Brian Boyle Plumbing Supervisor

Cory Hanson HVAC Supervisor

Zach Koskiniemi Electrical Supervisor

Craig Gast Locksmith

Erik Larson Locksmith

Jennifer Baker Associate Director of Public Health & Safety, University Police & Safety Office

Pete Lambertz Director of Network Engineering and Operations

North Dakota State University • Department of Facilities Management

Mailing Address

Contact Numbers

Web

NDSU Dept 3200

PO Box 6050

Fargo, ND 58108-6050

Tel (701) 231-7911

Fax (701) 231-8008

www.ndsu.edu/facilities

Design Guidelines Facilities Management

viii

Change Log

April 29, 2016 Change Log added

03 15 00-2 – Truncated dome information added

10 11 00-3-A – Markerboard size and mounting height added

21 05 00 – Fire suppression information added

23 20 00-2, -3 – Rigid and flexible HVAC piping information added

May 3, 2016 01 00 00-3 – Sample office layouts added

May 6, 2016 26 32 00-4 – Forms for generator installation added

May 11, 2016 26 50 00-4-B – Walkway lighting redefined

May 23, 2016 09 05 00-1-A and Exhibit C – 5% spare paint removed

09 90 00-4 – Eggshell finish for hollow metal door and frames

June 24, 2016 Exhibit H - The Owner/Contractor Contract Review and Checklist updated

July 14, 2016 00 10 00-3 – Consultant pre-bid requirements

01 00 00-4 – Lactation Room example added

03 35 00-1-B – Broom finish for sidewalks

05 50 00-1 – Stainless steel used for railings

09 60 00-3 – Classroom flooring changed from VCT to carpet tile

22 40 00-2-B – Tempered water for emergency shower/eye wash station

October 26, 2016 03 35 11 – Concrete Floor Finishes added

November 17, 2016 Exhibit H – Changes to Contract Review and Checklist

November 22, 2016 23 07 16-1 – Insulation type and thickness changed

November 29, 2016 26 50 00-4-C – Exterior Building Lighting section added

March 16, 2017 07 10 00 – Section removed

08 50 00 – Window information added

Division 10 updated

12 93 13 – Bicycle Rack information added

Exhibit C amended

April 7, 2017 06 41 00 – Cabinet lock information changed

April 20, 2017 Exhibit B - Bidder Questionnaire changed

June 1, 2017 Exhibit H-12 - Builder’s Risk information added

August 22, 2017 Exhibit P – Numerous changes

September 19, 2017 21 10 00 – Fire Protection System Impairment Procedure added

22 40 00-G-1, -2 – Aerator information added

Division 26 – Numerous changes

October 23, 2017 05 40 00 – Studs changed from “20 gauge” to “20 gauge EQ”

November 2, 2017 08 70 00-17-L-1,2,3 – Hinge information updated

November 8, 2017 Exhibit O – “no lead” water systems changed to “lead free”

December 20, 2017 08 11 16-2-A – Manufacturer added

21 10 00 – Fire Impairment Procedure amended

22 10 00-3 – Foam Core PVC not allowed

22 30 00 – Manufacturer list updated, sewage ejector changed from pedestal to submersible

January 2, 2018 22 40 00-1-H – Water cooler changed from recessed to wall hung

January 5, 2018 00 21 00-2 - Closeout Documents Submittal information added

February 5, 2018 08 70 00-12-A – Besam model number updated

May 1, 2018 01 56 00-1-D – Construction fence signage added

22 40 00-1-G – Fiberglass shower strainer information added

May 21, 2018 01 20 00 – Change Order information amended

22 40 00-1-E-1 – Shower valve information added

23 22 02-5-B – Wye strainer for PRV added

28 30 00 – Numerous changes

Design Guidelines Facilities Management

ix

September 26, 2018 23 05 00-1-A – Heating valve connection information added

26 05 00-6, -9 – Shunt trip breaker and Unfused disconnect information added

November 29, 2018 22 05 53-2-A-1, -2 – Pipe labeling clarified

22 10 00 -3-C –

March 29, 2019 Exhibit H-11, 12 – Updates to Contract Review and Checklist

April 8, 2019 23 05 00-7-B – Mechanical access platform/ladder information added

April 23, 2019 10 28 00 – Toilet partitions changed to floor mounted

23 22 02 – Steam piping information added

April 30, 2019 01 00 00-2-G-3 – Custodial Room shelving information added

May 30, 2019 08 70 00-17-C – All roof accesses shall be monitored

August 13, 2019 03 35 00 – Concrete cracking information added

October 3, 2019 08 70 00-11 – LM and Vandlguard door option removed

01 00 00-3-D – Office Layout Examples changed

October 30, 2019 01 14 00-6 – UAS/Drone procedures added

23 09 00-4-A – Static IP address information added

Exhibit A – Advertisement for Bids amended

December 18, 2019 01 60 00-1 – No sole source specifications amended

March 20, 2020 01 78 36-6, 7 – Warranty repair information updated

03 10 00-3 – Sidewalk and ramp slope information updated

08 05 00-1C – Bathroom door shall open out

08 70 00-17 – Door closures updated

10 28 00-2A – Paper towel and trash can information added

22 40 00-2 – Safety shower and eyewash station information updated

26 32 00-4 – Generator coolant sight glass

June 8, 2020 26 20 00-3-C – Shark 200 changed to Shark 250

June 23, 2020 12 30 00-5 – Teaching stations shall meet ADA

September 18, 2020 04 05 00-2, 3 – Masonry/tuckpointing information added

October 23, 2020 10 28 00-1-E, F – Toilet partition information added

November 3, 2020 01 78 44 – Stock Materials information updated

December 30, 2020 12 50 00-3 – Desktop/Keyboard area information added

January 5, 2021 00 21 00-3 – Method of Award information added

April 23, 2021 Exhibit H – Changes to Contract Review and Checklist

February 4, 2022 01 00 00-5 – Classroom design guidelines added

February 15, 2022 10 28 00-1-F – Partitions changed to be no gap

10 28 00-3 – Bathroom shelf added

June 28, 2022 03 35 00-4 – Concrete blowout repair added

July 20, 2022 23 05 00-28 – Warranty hazardous cleaning information added

September 8, 2022 01 78 44-2-F, G, H – Terrazzo, epoxy and polished concrete flooring extra stock added

October 10, 2022 Exhibit C – Closeout checklist updated

January 27, 2023 08 05 00-1-A-5 – Exit door hardware info added

June 16, 2023 10 28 00-2-B – Sanitary napkin dispenser removed

June 29, 2023 22 14 00-4, 33 46-00-6 – Storm Drain inlet information added

July 20, 2023 03 30 00-3 – Concrete strength updated

September 12, 2023 Exhibit P – Entire section updated

February 16, 2024 09 90 00 – Paint sheen and application temperature updated

08 70 00-9, 10, 11, 19 – Changes to flush bolts, mullions, exit devices and overhead stops made

March 6, 2024 23 60 00 – Quantech added to approved chillers

April 17, 2024 01 00 00-J – Provide filter pull area

23 20 00-6 – Side-stream filter to have ¾” or 1” view indicator

23 05 00-12-A – Glycol flush and fill

Design Guidelines Facilities Management

x

23 30 00-7 – AHU part availability

23 05 00-5 – BAS fire/smoke damper

23 09 00-11 – Fume hood controls

23 20 00-9 – Laser align pumps

21 05 00-3 – Recessed sprinkler heads

22 30 00-5 – Master hot water mix valve

22 10 00-12 – Water booster skid

22 05 00-9 – Valves for water meter

22 30 00-3 – No lab water

06 41 00-4-5-b – Soil traps

12 31 00-Part 2-3-C-11-a – Soil traps

22 30 00-4 – Soil traps

April 30, 2024 Division 26 – Numerous changes

28 10 00-1 – CBORD replaced with Avigilon

28 30 00-1, 3 – Protection Systems replaced with Honeywell Samewell

28 30 00-8 – Label all fire alarm devices

May 3, 2024 08 10 00-4-A,B – Glass doors and side light changes

08 70 00-9 – Door Position Switches

08 70 00-17-B – Parallel Arm Closers

12 36 00-3-A-1 – Marine edge for epoxy sink area

22 40 00 2-B-2 – Eyewash drain into sanitary line

May 14, 2024 27 10 00 – Numerous changes

27 10 05 – Numerous changes

May 16, 2024 32 80 00 – Pipe sleeve, controller, sprinkler heads, valves and repair work changes

Design Guidelines Facilities Management

xi

Definitions

Closed Interiors (Cabinetry)

Any closed storage unit behind solid door or drawer fronts, sliding solid doors.

Concealed Surfaces

(Cabinetry)

Any surface not visible after installation.

Exposed Tops (Cabinetry)

Any top of cabinet which is visible from an upper building level or floor such as a

mezzanine.

Open Interior (Cabinetry)

Any open storage unit without solid door or drawer fronts and units with full glass insert

doors and/or acrylic doors.

Other Exposed Surfaces

(Cabinetry)

Faces of doors and drawers when closed, and tops of cabinets less than 72 inches above

furnished floor.

Owner

For the purposes of the Design Guidelines “Owner” shall refer to the Department of

Facilities Management and/or the Director of Facilities Management (or designated

representative(s)).

Semi-Exposed Surfaces

(Cabinetry)

Interior surfaces which are visible, bottoms of wall cabinets and tops of cabinets 72

inches or more above finished floor.

Design Guidelines Facilities Management

00-1

Procurement & Contracting

00 10 00 Solicitation/Bid Advertisement

1) All bidding notifications shall be written by the Facilities Management Planning Department prior to

advertisement.

A) These notifications are to be advertised in the “Legal” section within The Forum of Fargo-Moorhead for a

period of twenty-one (21) days before the date of the opening of bids.

B) Additional notifications may be placed in a construction trade publication of general circulation among the

contractors, building manufacturers, and dealers in this state, and the Builders Exchange.

C) Advertisements shall be in compliance with NDCC § 48-01.2-05 and Part 6 of the NDUS Architects Manual.

2) The standard advertisement that shall be followed for bidding is supplied in Exhibit A.

3) Consultants – Send Ad and Plan Set via email to contractors with explanation/details of project. Provide Owner

with a list of which contractors were contacted and if they intend to bid the project or not one week prior to

the bid.

00 21 00 Instructions to Bidders

1) All requested alternates shall be bid. If no change in base bid is required enter the words, “No Change”.

2) On the Schedule of Values the Contractor is to insert a line item called Closeout Documents Submittal equal to

5% of the contract value to ensure timely submittal of closeout documents.

3) The contract will be awarded on the basis of base bid or combination of base bid and such alternates that

produce the most complete project as desired by the Owner within the allowable budget.

00 31 31 Geophysical Data

1) Contractor is responsible for all utility locates. Contact North Dakota One Call before any work is performed.

2) NDSU will be notified by North Dakota One Call and will locate its private utilities.

3) All repairs required due to disregard of marked locates shall be the contractors responsibility.

00 45 13 Bidder Qualifications

1) Complete “Bidder Questionnaire”, Exhibit B

2) If questionnaire is not submitted within the bid bond envelope the bid will be returned unopened.

00 72 00 General Conditions of the Contract

1) The design and execution of a project shall be in compliance with the Design Guidelines as written on the date

of agreement with the Architect/Engineer.

2) The Consultant shall be responsible to comply with all sections of this document, both in the design and

execution of a project. The Consultant will be responsible for rectifying any non-compliant items at their cost

through the errors and omissions clause of their contract.

3) Consultant shall be responsible for all site survey, geotechnical site evaluation, and construction materials &

methods testing.

4) The Consultants are required to consult with the Owner on matters pertaining to basic systems design.

5) Contractor is responsible to pay the sales and use tax on all owner supplied equipment as required. Consultant

shall verify with the owner if the owner will be supplying any equipment for a project and what the value of the

equipment is. The consultant will provide the value to the bidders prior to the bid opening. If the value is

unknown before the bid opening a change order will be written to cover the cost of the tax, bond, and insurance

costs.

6) Construction Plans

A) May not be sized larger than 30”H x 42”W (ARCH E1)

B) Shall include Building Number, provided by Owner.

C) Consult with Owner on Project Title.

7) Prior to assigning a room number schedule, consult with the Owner so the schedule on the plans will be the

room numbers used after the facility is occupied.

8) Exhibit J outlines the safety requirements and is to be included within the project specifications.

A) Contractors are required to submit a copy of their written safety program on projects estimated to exceed

$100,000.

Design Guidelines Facilities Management

00-2

9) Consultants shall confer with Owner about the Americans with Disabilities Act. North Dakota Century Code §

48-02-19 requires any person preparing plans or specifications for a public building provide a statement, to be

filed with the North Dakota Office of Intergovernmental Assistance, that, in their professional judgment, the

plans and specifications are in conformance with the American with Disabilities Act Accessibility Guidelines for

Buildings and Facilities. Exhibit N contains this Conformance Statement.

10) The Owner may want to salvage items from an existing building and/or site before it is built upon, demolished

or remodeled.

11) Contractor shall be responsible for protecting the new and existing irrigation system in the construction site.

Irrigation repair will be back charged to the contractor.

12) Contractor shall be responsible for protecting new and existing plantings pursuant to the protective measures

outlined in Section 01 56 39.

13) Prime Contractors shall be responsible for locating and marking buried utilities with paint and flags as needed

within the construction site until record documents (drawings), which indicate the location of all buried utilities,

are delivered to the Owner.

14) Vice President for Finance and Administration shall be signatory for all Contract cost change documents and

Agreements. FM representative may sign for Proposal Requests or similar preliminary documents.

Design Guidelines Facilities Management

01-1

General Requirements

01 00 00 General Project/Design Requirements

1) Stairwells and Stair Treads

A) Service and emergency exit stairwells shall be of reinforced concrete with an abrasive strip.

B) Emergency or other exterior stairways will not be allowed in new construction projects or renovation

projects. All stairways shall be contained internally within the building design.

2) Service Rooms and Spaces

A) These service closets shall be provided on every floor, no more than 250 feet apart.

B) Custodial closets should not be located in or accessed through restrooms. It is advisable, though, to design

the custodian's closet between the men's and women's rest rooms, with an access door leading to the

common pipe chase.

C) Custodian rooms shall have a minimum ceiling height of eight feet.

D) Specify sealed concrete or epoxy flooring and FRP at wet areas and high impact drywall for the remainder.

E) Supply at least 50 foot candles of lighting in the space.

F) Implement a self-closing door with a hold open device.

G) Provide the following fixtures:

1) A duplex 120 volt outlet with ground fault circuit interrupt protection.

2) A rack with mop holders for hanging a minimum of three mops and three brooms.

3) Sixteen (16) inch deep shelves, sixteen (16) inches apart vertically, starting 30” above floor. Verify

shelving lengths with Owner.

4) Twenty four (24) inches by twenty four (24) inches service floor sink with hot and cold water.

H) Clear access of thirty six (36) inches by forty eight (48) inches is needed for a custodial cart.

I) Provide interior space for storage of recycling containers/bins.

J) Provide enough room to allow for filter replacement of AHU, CUH, etc.

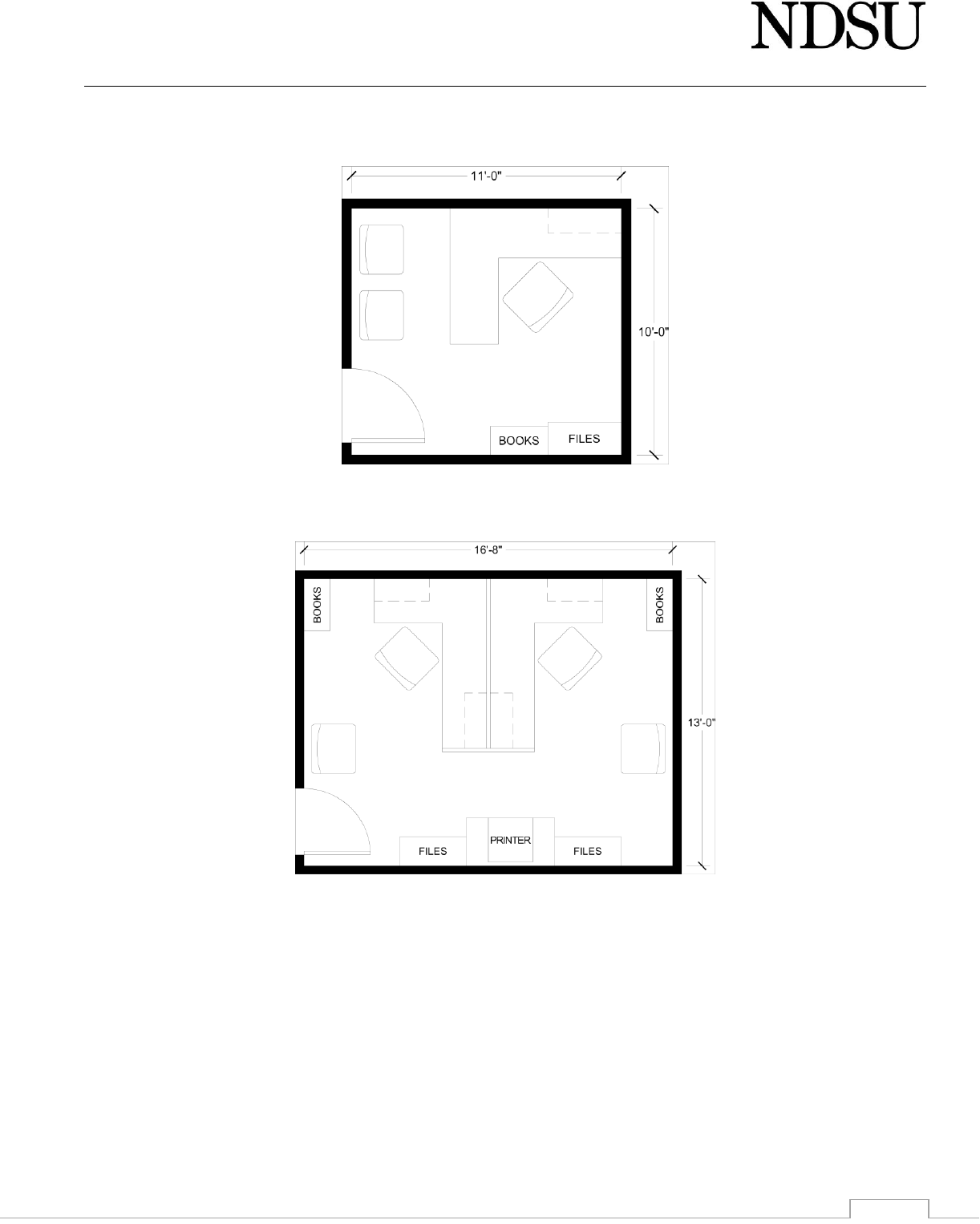

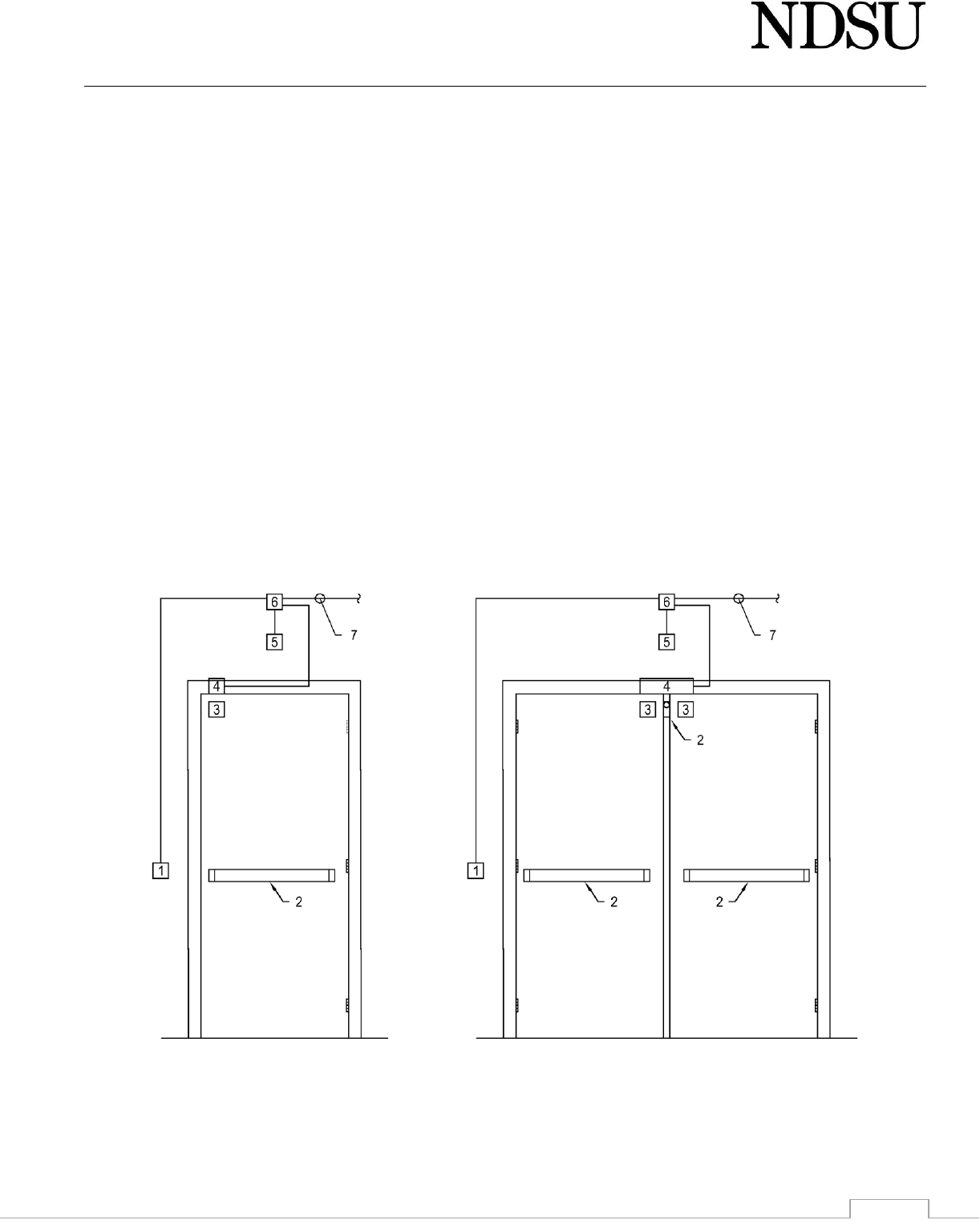

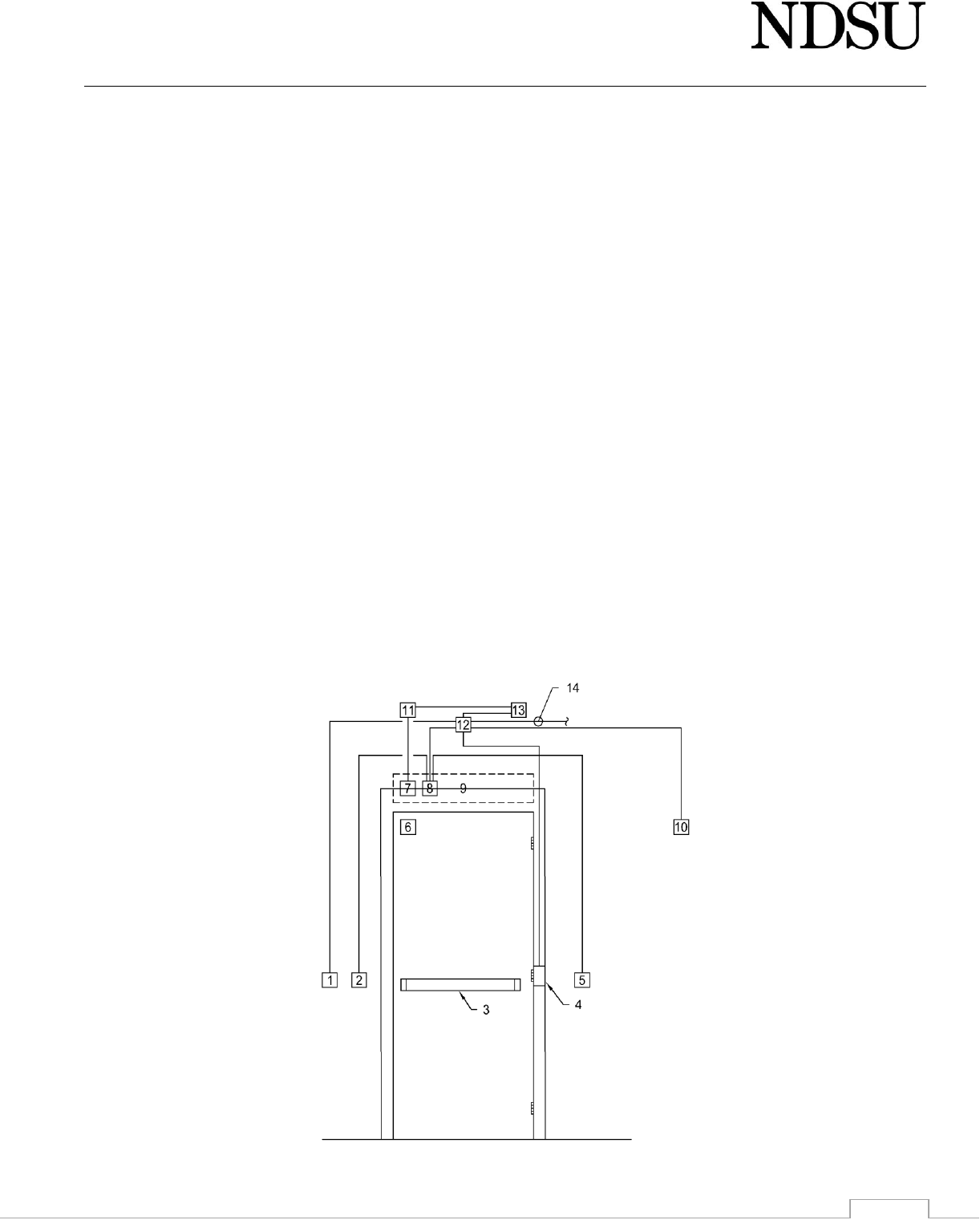

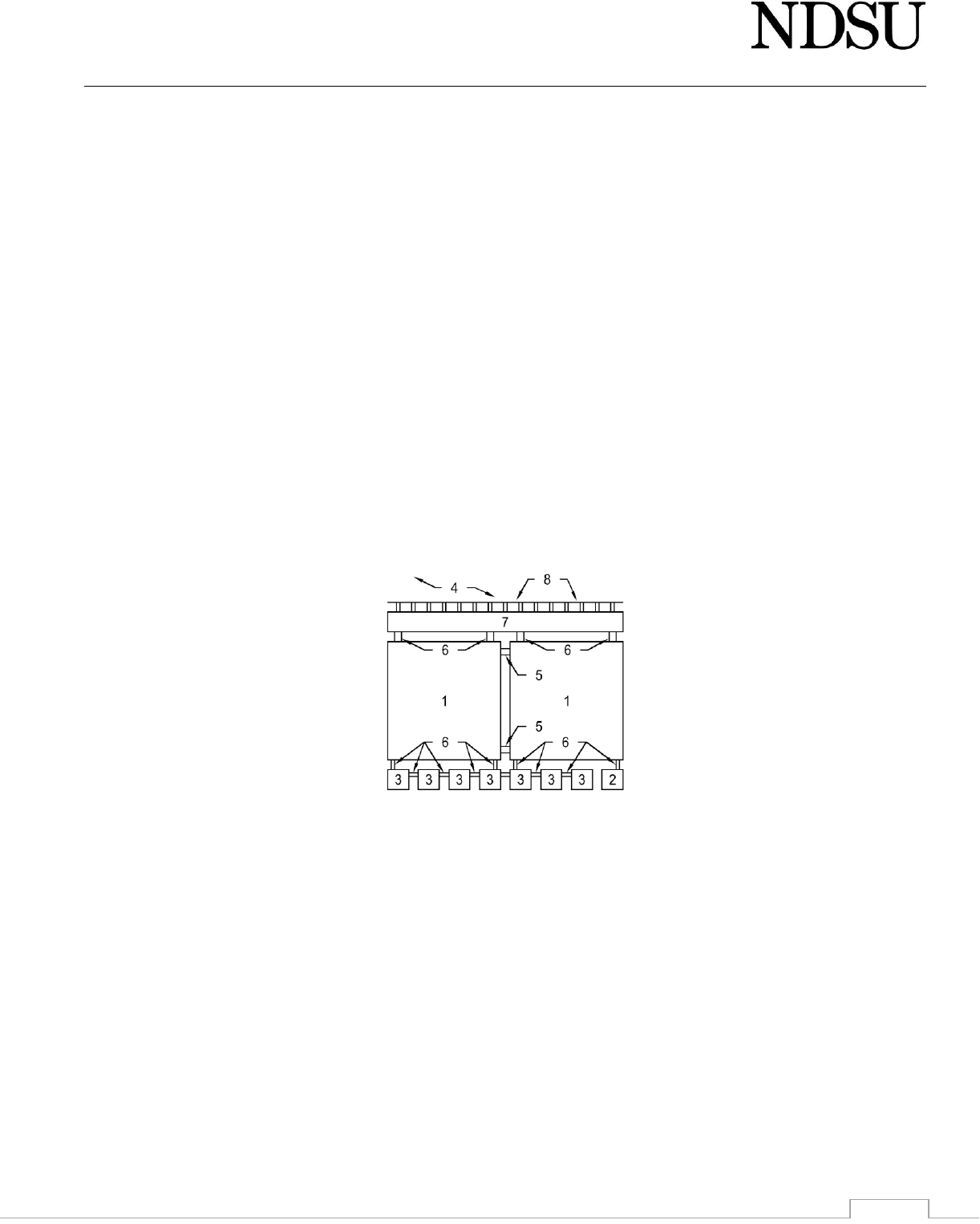

3) Office layout examples

A) Below are some examples of diagrammatic office layouts shown to help visualize efficient space

configuration. The office sizes shown align with the University Space Allocation Guidelines and indicate

NDSU expectations.

B) While private offices for staff (administrative and research) and graduate students are generally preferred

over modular workstations, open office systems are being increasingly utilized both in the corporate sector

and on campus. Implementing a modular planning approach can provide countless layout options while

preserving the flexibility of a space for changes in future programmatic requirements.

C) It is understood that existing buildings (especially older buildings) do not always offer uniform sized spaces

and may prevent precise conformity to the Space Allocation Guidelines. Nonetheless, these layouts present

a sampling of commonly used arrangements for reference in planning the use of your spaces and can be

adapted to various sized rooms.

D) Associate Dean, Director, Chair office – 180 square feet.

Design Guidelines Facilities Management

01-2

1) Unit head’s office is an individual, private office able to contain a desk, file cabinet(s), book shelves and

a meeting area for up to four people.

E) Full-time Faculty / Staff / Emeritus Faculty office – 110 square feet.

1) Full-time, professional and administrative staff and emeritus faculty office that will accommodate a

desk, file cabinet, bookshelf and an area capable of holding meetings.

F) Shared Staff office – 120 square feet per person

1) Shared offices can provide a viable option when space is limited or when staff work on similar tasks.

When personnel do not require a private office work when they work with sensitive documents, a

shared office may prove more secure than an open-office layout.

Design Guidelines Facilities Management

01-3

G) Post Doc – 100 square feet

1) Post doctorate fellows, research assistant or technician requiring the privacy and security of an

individual office.

H) Scholars / Fellows / Grad associate – 40 square feet per person

1) Visiting scholars, Fellows and Trainee offices are assigned shared office space occupied by two or more

persons depending on the type of appointment (full or part-time), program needs and existing building

conditions. The figure above shows one possible layout for associates sharing a single office. Modular

work stations at 7’x6’ each are also an excellent option.

4) Lactation Room example

5) Guidelines for Creating and Remodeling Learning Spaces can be found at:

https://www.ndsu.edu/fileadmin/provost/LSEC/NDSU_Classroom_Design_Manual.pdf

Design Guidelines Facilities Management

01-4

01 14 00 Work Restrictions (Site Access, Occupant Coordination, Site Use)

1) Tobacco is not permitted on Campus grounds or in buildings and structures. Anyone caught using tobacco

products on campus will be removed from the jobsite.

2) Consuming prepared foods is allowed on the construction site and within the building. If this privilege is abused,

food will no longer be allowed within the building and must be consumed in a job trailer or outside the building.

3) Radios, tape players, compact disc players, etc. will not be allowed.

4) Owner reserves the right to halt all work on the construction site if the work is interfering with nearby facilities

until that interference is corrected. Owner will provide the contractor with adequate information so this

condition could be avoided; however, University activities may not be interrupted.

5) Contractor shall provide a minimum of 48 hour notice of utility or service shutdowns.

6) Unmanned Aircraft Systems (UAS) or drone flights shall follow the procedures located at the following address:

A) https://www.ndsu.edu/research/for_researchers/unmanned_aircraft_systems/

01 20 00 Change Order Procedures

1) A Change Order is a written instrument prepared by the Architect and signed by the Owner, Contractor and

Architect stating their agreement upon all of the following:

A) The change in the Work;

B) The amount of the adjustment, if any, in the Contract Sum; and

C) The extent of the adjustment, if any, in the Contract Time.

2) When either or both additions and credits covering related work or substitutions are involved in any one change,

the allowance for overhead and profit shall be calculated on basis of the net amount of cost or credit.

A) The allowance for overhead, bond, and profit combined, included in the total cost shall be based on the

following schedule:

1) For the Contractor; for added or deleted work performed by the Contractor’s own forces, 10 percent

of the cost.

2) For the Contractor; for added or deleted work performed by the Contractor’s Subcontractor, 5

percent of the cost due the Subcontractor.

3) For each Subcontractor or Sub-subcontractor involved; for added or deleted work performed by the

Subcontractor’s own forces; 10 percent of the cost.

4) For each Subcontractor; for added or deleted work performed by the Subcontractor’s Sub-

subcontractor, 5 percent of the amount due the subcontractor.

B) In order to facilitate the checking of quotations for extras or credit, all proposals, except those so minor

that their propriety can be seen by inspection, shall be accomplished by a complete itemization of costs

including labor, materials, and subcontracts. Labor and materials shall be itemized in the manner described

above. Where major cost items are subcontract, they shall be itemized also.

C) In no case will a change involving over $100.00 be approved without such itemization.

01 31 00 Coordination

1) Contractor shall coordinate an above ceiling inspection of all rooms by providing a 48 hour notice before ceiling

tiles are installed for owner’s personnel to view above ceiling areas for locations of valves, VAV boxes, etc.

2) Communication is of the utmost importance and the proper lines of communication often avoid unnecessary

delays and misunderstandings.

3) Progress Meetings:

A) Required Attendance:

1) Architect and their professional consultants, as needed.

2) Prime Contractor’s project manager and field superintendents/foremen. Subcontractors and suppliers

as appropriate to the agenda.

3) All Prime Contractors shall have any subcontractor(s), who are within a 2 week window of starting

work, present at the progress meetings for the purpose of coordination of their work with all others

working on the site.

4) Onsite Coordination Meetings:

A) The General Contractor’s Superintendent shall conduct a brief daily coordination meeting with site

superintendents/foremen of the other Primes, and all subcontractor foremen that are working on site, for

Design Guidelines Facilities Management

01-5

the purposes of onsite communication, coordination and dissemination of information.

5) Schedule Coordination

A) The overall construction schedule is managed by the General Contractor. All Prime Contractors are

responsible for coordinating their work through the General Contractor and cooperating with all trades to

ensure the work progress of others is not impeded.

01 33 00 Submittals

1) Provide the Owner with one copy of Shop Drawings for review when forwarded to Consultant from Contractor.

The Owner will review each submittal and reply to appropriate Consultant if modifications need to be made.

2) Shop drawings for review and “For Construction” will be submitted to the Owner in digital format, with hard

copies provided in the Operation & Maintenance Manuals only.

3) Schedules:

A) The overall construction schedule, approved and signed by all of the Prime Contractors, must be submitted

within three (3) weeks of the date of the Contract.

B) The first schedule signed off by all of the Prime Contractors, and approved by the Architect and Owner will

be the schedule for the project. Subsequent schedules will show variances to the schedule, accurately

indicating tasks that are behind, ahead or on schedule. The schedules will be created in a scheduling

program such as Microsoft Project, SureTrack/Primavera or Expedition that is capable of showing the

progress and any variations accurately. Electronic copies will be made available to the Architect and/or

Owner upon request.

C) Schedules will be updated by the General Contractor, with the coordination, cooperation and input by the

other Prime Contractors. The other Prime Contractors shall supply tasks, accurate dates and timeframes for

purpose of completing the schedule expeditiously and accurately. Copies of this updated schedule will bear

the signatures of all Prime Contractors acknowledging their acceptance. Signed copies shall be provided to

the Architect and Owner one (1) week prior to submission of all Applications for Payment.

D) If a Prime Contractor falls behind on the schedule due their lack of manpower, equipment, coordination

with other Prime Contractors, or their own negligence, the Owner will direct the Prime Contractor to use

whatever means necessary to get back on schedule. This may include, but is not limited to, working

overtime, increasing manpower, or bringing in additional forces all at the expense of the Prime Contractor.

If so directed, the Contractor shall abide by the direction of the Owner or risk being in breach of contract,

allowing the Owner to hire additional forces to recover the lost time and deducting the cost from the Prime

Contractor’s contract.

01 35 00 Special Project Procedures

1) Storm Water Pollution Prevention Plan

A) Storm water permitting shall follow NDDH guidelines and the following procedure:

1) The Consultant shall on behalf of the Owner provide the Contractor with a preliminary Notice of

Intent (NOI), Storm Water Pollution Prevention Plan (SWPPP), and Acceptance of Ownership form

upon award of the project contract.

2) The Contractor shall review, amend, complete, and sign all required components of the NOI, SWPPP

and Acceptance of Ownership form. Additional sediment and erosion control Best Management

Practices (BMP’s) and other features including a proposed timetable of sediment and erosion control

activities shall be added to the SWPPP by the contractor:

http://www.ndhealth.gov/WQ/Storm/Construction/ConstructionHome.htm

3) The contractor shall return the completed NOI, SWPPP, and Acceptance of Ownership form to the

Consultant and allow for a minimum of two (2) days for review and approval of the NOI and SWPPP

by the Owner or its designated representative prior to signature of the NOI by the Owner. The Owner

does not sign the SWPPP.

4) The NOI shall be submitted by the Consultant on behalf of the Owner to the NDDH 7 days prior to

commencement of construction. The contractor shall not begin Construction activities prior to the

seventh (7th) day after submittal of the NOI to the NDDH or until acknowledged in writing by the

NDDH, whichever is sooner.

5) If the project involves 50 or more acres, or if the project has a discharge point located within 2,000

feet of, and flows to, a water body listed as impaired under section 303(d) of the Federal CWA due

Design Guidelines Facilities Management

01-6

to sediment or parameters associated with sediment transport, the SWPPP shall be submitted with

the Notice of Intent to the NDDH. A list of North Dakota’s water quality-limited waters needing total

maximum daily loads or TMDLs developed to comply with section 303d of the Federal CWA can be

found at: http://www.ndhealth.gov

B) By signing the Contract and completing the NOI, the Contractor is a co-permittee with the Owner to ensure

compliance with the terms and conditions of the General Storm Water Permit and is responsible for

complying with all provisions of the permit. The contractor is solely responsible for the execution of the

SWPPP according to Part II C of the General Storm Water Permit

C) Fire walls, fire barriers, fire partitions, smoke barriers and smoke partitions or any other wall required to

have protected openings or penetrations shall be effectively and permanently identified with signs or

stenciling. Such identification shall:

1) Be located in accessible concealed floor, floor-ceiling or attic spaces

2) Be located within 15 feet (4572 mm) of the end of each wall and at intervals not exceeding 30 feet

(9144 mm) measured horizontally along the wall or partition

3) Include lettering not less than 3 inches (76 mm) in height with a minimum 3/8 inch (9.5 mm) stroke

in a contrasting color incorporating the suggested wording. "FIRE AND/OR SMOKE BARRIER—

PROTECT ALL OPENINGS" or other wording.

4) Exception: Walls in Group R-2 occupancies that do not have a removable decorative ceiling allowing

access to the concealed space.

01 51 00 Temporary Utilities

1) Temporary utility services for the construction site will be installed by the appropriate contractor and must be

coordinated with the Owner prior to connections being made.

2) Electrical Power Service:

A) Temporary power shall be installed following NEC Article 590.

B) Power will be available to the site from a near-by transformer or building and will be metered with a

Contractor-provided meter.

C) NDSU will read the meter and bill the General Contractor accordingly; Xcel Energy will not meter nor read

the meter at the site.

D) Depending on the job size, power may be supplied without cost at the discretion of the Owner.

3) Water Service:

A) Water will be available to the site from a near-by University water distribution source with a backflow

prevention device and will be metered with a Contractor-provided meter.

B) NDSU will read the meter and bill the General Contractor accordingly; City of Fargo will not meter nor read

the meter at the site.

C) Depending on the job size, water may be supplied without cost at the discretion of the Owner.

4) Heat and Steam Service:

A) All Work that requires heat in new construction will be the responsibility of the Contractor.

B) Through an agreement with the Owner, the Contractor may buy steam from the main Campus steam

distribution system.

C) Usage of the steam will be billed back to the Contractor based on a value per thousand pounds of steam

condensate measured through an Owner supplied condensate meter.

5) Telephone, Internet and Fax Service:

A) Telephone, Internet and fax services may be provided through the NDSU Telecommunications department

and billed to each Prime Contractor that requires a connection.

B) Cellular phone service will be the responsibility of the Contractor.

6) Abuse of the Owner-provided temporary services will result in the Owner billing the contractor for those utilities

being abused.

A) Prior notification will be provided to the Contractor of abuse to cease the abuse.

B) The Owner will make the final decision on who the abuser was and the amount of wasted services.

01 52 00 Construction Facilities

1) Sanitary Facilities:

A) Contractors may be allowed to use the facilities for Work that will take place in a building with existing,

Design Guidelines Facilities Management

01-7

operating sanitary facilities.

B) Care must be made to keep these facilities in a clean and sanitary condition.

C) The General Contractor will be responsible to supply portable toilet facilities at the site for new

construction. Nearby buildings will not be allowed unless the General Contractor has received permission

from the Owner.

2) Site Storage:

A) All material and equipment shall be confined to the area allowed by Owner unless prior approval was

granted to store material outside the area of work.

B) Excess black dirt may be reused on the NDSU campus at Owners discretion.

C) Excess clay or contaminated material will be removed from campus and become the property of the

Contractor.

01 55 00 Vehicular Access and Parking

1) Traffic routes will be as directed by the Owner.

2) ON-CALL SERVICES:

A) Any contractors/vendors performing on-call (non-scheduled) services to NDSU buildings or property may

do so WITHOUT purchasing any type Parking Permit from NDSU, but their vehicle(s) shall meet the following

criteria to be eligible for parking on NDSU property.

1) Vehicles shall be easily recognizable as a commercial service vehicle.

2) Vehicles shall be painted on the exterior with a 'branded logo' or have an appropriately sized

magnetic or attached sign.

3) Vehicles shall be parked in legal and/or authorized parking areas or they will be subject to parking

citations.

3) LONG-TERM SERVICES:

A) Any contractors/vendors performing on designated long-term NDSU projects shall also be allowed to park

on NDSU property if their vehicle(s) meet the same criteria as stated above.

B) Contractors/vendors shall be instructed of the work site parking conditions at the pre-performance

conference and shall confer with their assigned NDSU Project Manager as to where they shall park their

company vehicles while working on NDSU property.

4) UNMARKED CONTRACT/VENDOR VEHICLES

A) Shall NOT be allowed to park on NDSU property without purchasing an NDSU parking permit. Failure to

purchase a parking permit while parked on NDSU property will result in a parking citation.

5) NDSU PARKING PERMIT PURCHASE OPTIONS

A) One-Year Parking Permit for Contractors/Venders = $185.00 per year

B) One-Day Parking Permits for Contractors/Venders = $2.00 per day

C) Temporary Parking Permits for Contractors/Venders = $2.00 per day (Maximum of 6-weeks)

D) Summer Parking Permits for Contractors/Venders = $25.00 summer only (May 15 to August 15

approximately)

E) Metered parking at any of the four pay lots on the NDSU campus.

6) NOTES:

A) Contractors'/vendors' shall determine which permit or combination of permits works best for their

situation.

B) There are no refunds for parking permit purchase fees. All sales are final.

C) All citations received are the responsibility of the vehicles registered owner.

D) CONSULT YOUR NDSU PROJECT MANAGER ABOUT BUYING PARKING PERMITS AND METERED LOTS.

01 56 00 Temporary Barriers and Enclosures

1) The Contractor shall confine apparatus, material storage, and the operation of the workers to limits indicated

by the construction site boundaries.

A) These boundaries are to be fenced-off by use of a chain link fence at minimum height of six feet and

maintained in good condition through the completion of the project.

B) If this confinement is not possible, prior approval must be obtained from the Owner, via the project

Consultant, before other University space is utilized by Contractor.

C) As per state law and city ordinance regarding trespassing, the name of the person posting the premises

Design Guidelines Facilities Management

01-8

must appear on each sign in legible characters.

D) The signs shall read:

No Trespassing

Violators will be Prosecuted

(Contractors name)

(Contact Name) – could be a foreman, supervisor, project manager, presidents name

E) Place at all entry gates, areas of egress, and every 40-50 feet along fence.

2) Site Traffic:

A) Contractor may not block traffic or pedestrian use other than designated work area.

B) Contractor shall supply and maintain all barricades to block-off the work area.

01 56 39 Temporary Tree and Plant Protection

1) Protect all existing trees and other planting areas that will not be directly affected by the work. Existing trees

and other planting areas which are damaged due to work shall be repaired or replaced to original condition.

A) Fence shall be installed 3’-0” beyond the drip line of trees and plantings.

B) No equipment or materials shall be placed within the protected fencing.

C) No chemicals, dirt, or construction debris shall be placed within the protected fencing.

D) There shall not be cutting or breaking of branches without notifying the Owner’s Landscape/Arboretum

Coordinator.

E) No damage shall be done to the tree trunks; this includes bark removal, cutting into the trunk, equipment

leaning against the trees, etc.

F) When excavation operations are in proximity to trees, the root system shall be cut by hand at the limits of

the excavation prior to any soil removal.

01 57 00 Temporary Controls

1) Erosion and sediment control is required on all construction projects; contractor shall comply with the local

authority having jurisdiction and NDPES requirements and procure the appropriate permits.

01 60 00 Product Requirements

1) This paragraph must be included in the specifications for every project:

A) Proprietary Specification Requirements: There are no proprietary specifications in this project. No product

will be sole sourced. Substitutions are allowed for all products, as long as the procedures indicated within

these specifications are adhered to. Substitutions must be approved by the architect prior to acceptance.

2) The products and materials listed in this Guideline are those that NDSU has utilized and currently requires.

A) Any product or material that may be substituted requires prior approval by the Owner.

B) Within the specifications, require seven working days prior to the date of receipt of bids for review of

substitutions by the Owner and the Consultant.

C) No substitutions will be considered after the project has begun unless provided within the Contract.

3) No products or building materials used as a temporary or permanent element in the construction of a building

will be allowed which have any form of asbestos containing or lead containing material.

A) Contractors shall be responsible to monitor shop drawings and product literature to verify the make-up of

materials to be used in the building, and to remind material suppliers that their products must not contain

asbestos or lead.

B) Contractors shall notify the Architect immediately of any materials which are suspected of containing

asbestos, and shall not disturb or attempt to abate any asbestos containing material. The Architect will

contact the Owner and inform the Owner of the Contractors observations. The Owner will obtain and

provide the services of professionals skilled in asbestos or lead removal.

C) At the completion of construction, during the close-out phase of the project, Contractor shall complete the

Contractor Certificate of Non-Asbestos and Non-Lead Materials (See 01 78 00.10.A) (Exhibit O).

4) Use poured concrete foundations, avoiding block wall foundations on exterior walls.

5) Architectural surfaces:

A) All surfaces should be hard surfaced, such as, brick, stone, structural concrete, marble, etc.

Design Guidelines Facilities Management

01-9

B) Exclude plastic or other types of surfacing materials which might require replacing or refinishing in future

years.

C) No exterior surfaces should require painting.

D) Other exterior metals should be corrosion free and non-ferrous, for example, stainless steel and/or

anodized aluminum.

E) Baked enamel steel is acceptable for roof and downspout applications.

01 73 00 Execution

1) The Consultant is responsible for maintaining accurate AS-BUILT drawings and specs showing any changes to

the contract documents.

01 74 00 Cleaning and Waste Management

1) All construction debris shall be removed from the site on a daily basis.

2) Cleaning:

A) All Contractors will keep the premises free from waste material accumulation, or rubbish created by the

construction project. Cleanup shall be conducted every day, with a thorough cleaning by all contractors by

end of the work week.

B) If the project is an interior renovation in an occupied building, the building shall be thoroughly cleaned daily.

Consult with the Owner on cleaning requirements.

C) If the Owner should determine the Contractor to be negligent in this respect, the owner reserves the right

to use his own resources for such cleanup. The cost will be charged back against the Contractor.

3) Contractor shall be responsible for performance of any lawn care and weed control measures within the

designated construction site to prevent the passive cultivation and seeding of unwanted plants.

01 77 00 Closeout Procedures

1) Upon completion of the project and before final payment is made, the Consultant shall complete the

requirements of sections 01 77 00 through 01 78 44.

A) All documents required in these sections shall be delivered to Owner.

2) Mechanical close-out requirements

A) Final inspection by the Owner will not be conducted prior to delivery of all air balance and performance

data, plus a spare parts list, operating instructions, and equipment descriptive literature that contains

complete numbered replacement parts list.

B) Test data information will be obtained by an independent firm. The firm shall be responsible to Owner.

C) Air flow, temperature, ampere readings, etc., shall be recorded and become the property of the Owner.

3) Warranty inspection:

A) The respective consultants shall set up a final warranty inspection on the eleventh month after substantial

completion (referred to as “One Year Warranty Inspection”).

B) The Architect shall arrange for an inspection of the mechanical systems 10 months after date of final

acceptance for the purpose of work that should be corrected under the one year guarantee provisions of

the contract.

01 78 00 Closeout Submittals

1) Exhibit C of these Guidelines contains the check-off sheet for the items in this section.

2) One copy of field noted, construction drawings (“Red Line Drawings”) shall be delivered to Owner.

3) Record Drawings:

A) Two (2) complete printed sets of Record Drawings:

1) May not be sized larger than 30”H x 42”W (ARCH E1)

2) Drawings must be updated to reflect all change orders, field changes, and revisions. Handwritten

notations and field notations are not acceptable.

B) One (1) set of electronic Record Drawings:

1) Must be in AutoCAD “.dwg” format.

2) Final electronic Record Drawings must reflect all field changes & revisions.

4) One (1) updated hardcopy of the specifications with addendum(s) incorporated into the specifications and a

copy of the updated specifications in PDF (or .doc/docx) format.

Design Guidelines Facilities Management

01-10

5) A painting schedule noting all paints and stains used on the project. Designate this information by using the

room number.

6) A valve chart for all valves will be provided with valve enumeration, location, and type identified (i.e. Main Shut-

Off, Return Valve, etc.).

7) A complete set of shop drawings.

8) The sign-in sheet listing all owner's employees at the training function provided as part of “Equipment Operating

Instruction” (required in 01 79 00.1.B).

9) HVAC system testing and balancing reports (required in 01 77 00.2).

10) The following completed documents:

A) A Contractor Certificate of Non-Asbestos and Non-Lead Materials (Exhibit O).

B) AIA G704-2000 Certificate of Substantial Completion; or,

1) AIA G704CMa-1992 Certificate of Substantial Completion, Construction Manager-Advisor Edition

may be substituted if applicable; or,

2) AIA G704DB-2004 Certificate of Substantial Completion of a Design-Build Project may be substituted

if applicable

C) AIA G705-2001 List of Subcontractors

D) AIA G706-1994 Contractor’s Affidavit of Payment of Debts and Claims, including AIA G706A-1994

Contractor’s Affidavit of Release of Liens

E) AIA G707-1994 Consent of Surety to Final Payment

F) Certificate of Occupancy issued by the local authority

01 78 23 Operation and Maintenance Data

1) Operating and Maintenance Manuals:

A) Two (2) hardcopy of instructional operating and maintenance manuals and product information on all

equipment and finish materials.

1) Items shall be indexed according to the Construction Specification Institutes indexing system and

separated by a tab system (ie: 05 50 00 Metal Fabrications).

B) One (1) electronic copy in PDF format of instructional operating and maintenance manuals and product

information on all equipment and finish materials.

C) Include part books on every piece of equipment that operates or has moving or electrical parts, for example:

elevators, door hardware, alarm systems, etc.

D) Warranties:

1) Include all warranty information, cut sheets, and owner’s manual which is to include the operating

procedures, product maintenance schedule, and maintenance requirements.

01 78 36 Warranties

1) Warranty items will be repaired within one (1) week. If not repaired, Owner will have the item in question

repaired and will invoice the responsible party.

2) Roofing Contracts:

A) A contractor’s “Five Year Roof Guarantee” (Exhibit D) shall be completed by the contractor for all roof

projects and submitted to Owner.

B) Manufacturer’s membrane roofing warranties shall be a minimum of twenty (20) years.

C) Sheet metal roofing warranties shall be a minimum of 20 years.

3) Casework shall be provided with a five (5) year guarantee against defective material and fabrication.

4) Warranties are to be included with Operation and Maintenance Data submittals, see also 01 78 23.D

5) NDSU will charge back to the contractors and/or suppliers time spent by Owner staff investigating and

diagnosing items that turn out to be warranty claims.