Statistical Process Analysis using

NWA Quality Analyst software

and Agilent OpenLAB

ECM Intelligent Reporter

Application Note

Abstract

Statistical Process Control (SPC) is a well-established element of ISO 9001 certified

quality management systems. Northwest Analytics (NWA) Quality Analyst software offers

advanced statistical functions to analyze chromatography data system (CDS) result data

stored in Agilent OpenLAB ECM. This note describes how NWA Quality Analyst software

could be used with OpenLAB ECM and ECM Intelligent Reporter.

Introduction

Quality assurance and quality improvement

are important elements of ISO 9000

Quality management systems

1

. Statistical

Process Control (SPC), Process capability

analysis, process performance analysis, and

regression analysis are important statistical

techniques helping you not only to achieve

planned results but also to continually

improve your production and lab processes

2

.

While processes operate within

specifications they still might be out of

statistical control resulting in random out-of-

spec situations.

SPC helps identify single event or systemic

reasons for deviations and uncover

opportunities for process improvements

3

.

This is not only limited to manufacturing,

chemical, or pharmaceutical production

processes, but it can be applied to general

lab operation and method validation

processes. According to the ISO / IEC

17025: “data shall be recorded in such

a way that trends can be detected and

statistical techniques can be applied

to review Results”. SPC can also help

laboratory‘s top management to “conduct

a review of the … testing and/or calibration

activities to ensure their continuing suitability

and effectiveness”

4,5

.

To get the best understanding of laboratory

trends, large amounts of data, collected over

months or years will provide a higher level

of statistical significance. With the Agilent

OpenLAB ECM Intelligent Reporter result

database analytical quantitation results

generated by Agilent OpenLAB CDS or

Waters Empower can be stored for several

years - across multiple labs and across larger

time ranges.

The Agilent Report Template Editor or SQL

Server Report Builder allows you to generate

e.g. method, instrument and/or compound

specific result charts (see figure1). Microsoft

SQL server Reporting Services technology

refreshes and publishes web-based reports

in an unattended mode.

When developing new processes, or

improving or troubleshooting existing

processes you need to handle your data

in a more interactive way and apply

various statistical methods to find the

most applicable one. Amongst a variety of

software packages for advanced statistics,

this note describes how to use NWA

Quality Analyst with Agilent OpenLAB ECM

Intelligent Reporter. The setup is described

in an associated technical note Connecting

NWA Quality Analyst software to Agilent

OpenLAB ECM Intelligent Reporter

6

Software requirements

Visit http://www.nwasoft.com/products/

nwa-quality-analyst to request a free trail

copy of NWA Quality Analyst.

Please write to Dana Petrusich (dpetrusich@

nwasoft.com) for additional sales

information.

Data backend:

Agilent OpenLAB ECM 3.4.1 with

Agilent OpenLAB ECM Intelligent Reporter

A.02.0x

Supported CDS systems:

Agilent OpenLAB CDS rev. A.01.03 or higher

Waters

®

Empower

®

2 or 3

2

Functionality of NWA Quality

Analyst in sum

Complete SPC Charting – Includes

variable and attribute control charts, process

capability analysis and process based

analytics and visualization.

Charting Automation – Procedures easily

automated with wizard based “Run File”

scripting. Routine charting operations can

be called from OpenLAB ECM client with a

single icon.

Examples

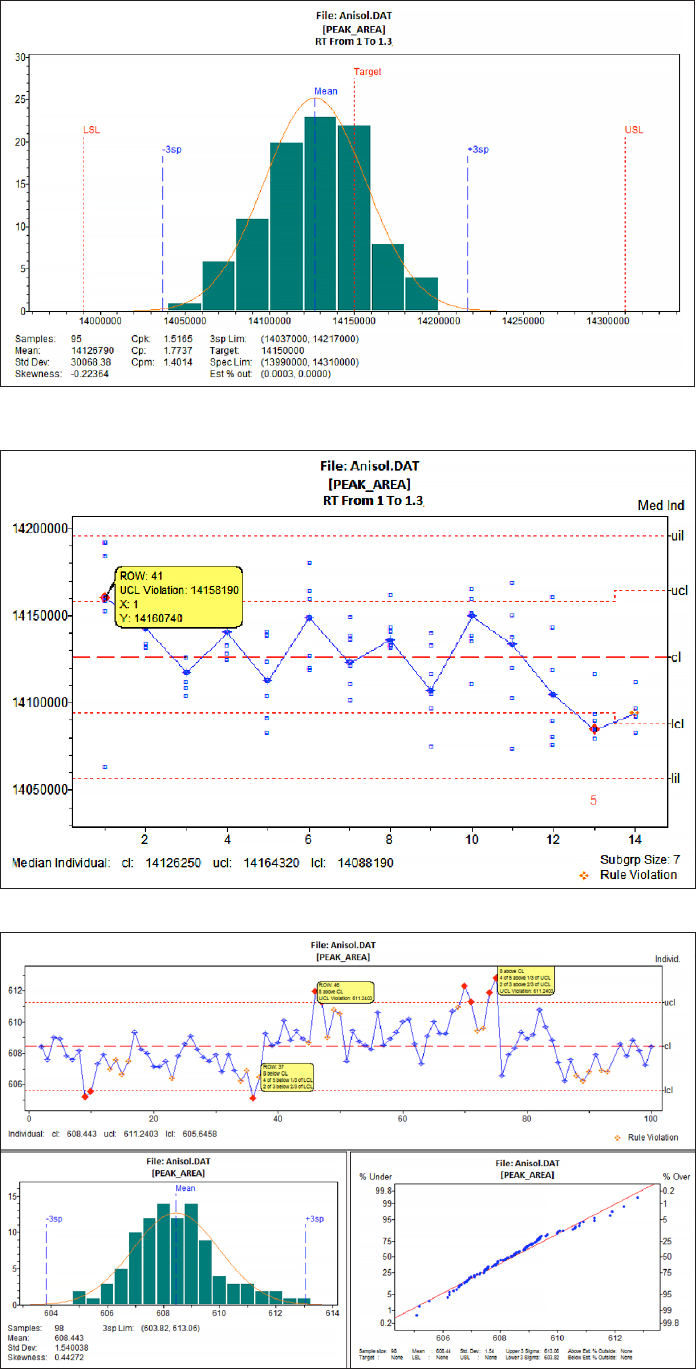

Figure 2 shows the result of a process

capability analysis. The detected peak area

for Anisol in a series of 95 analyses is plotted

in a histogram to visualize the distribution

type of the result data. A normal distribution

is a requirement for applying basic tools of

SPC. The diagram shows also the target,

and the Upper and Lower Specification limits

(USL, LSL) of the process. The capability

index C

p

is calculated by comparing the

width of the specification range with the

range of a short term 6σ band. If the ratio is

greater 1.5 the process is considered to be

“capable” and the potential for the analysis

to meet specifications good.

The C

pk

value relates the closer specification

limit to the mean value. It takes into account

that processes are not always perfectly

centered and bigger differences in C

p

and

C

pk

indicate an opportunity for process

improvement

3

.

Figure 3 shows a control chart based

on subgroups of 7 analyses. Individual

values and medians of each subgroup

are plotted against the number of groups.

Since standard deviations become smaller

with increasing numbers of samples, the

Upper and Lower Control limits (UCL, LCL)

are calculated based on a fixed number

of samples. They are adjusted if the

subgroup contains less than 7 data points to

compensate for the expected difference.

Deviations potentially related to a single

event (“special cause”) are indicated by red

dots and tool tips provide information about

the violated evaluation rule. Selection of

evaluation rules and control limits requires

good knowledge of the underlying statistical

rules in order to prevent false alarms

3

.

Figure 4 combines an individual value

control chart with a histogram and a normal

probability plot (Q-Q plot). The normal

probability plot visualizes the deviations from

a theoretical normal distribution of results.

Although a histogram of normal distribution

may be within specification limits, it does

not show the history of data collection and

possible trends.

Figure 1. ECM Intelligent Reporter: Individual values control chart with trend and imbalance

notification (Shewart rules)

Exception Reports – Reports can be

configured to show exceptions based

on specification, SPC and pattern rule

violations. Includes integrated Assignable

Cause / Corrective Action logging.

Industry and Application Specific

SPC Modules – Specialized modules such

as Multivariate SPC and Stability Analytics

add additional capabilities to

NWA Quality Analyst.

3

Figure 2. NWA Quality Analyst:

Histogram plot of Anisol peak areas

showing the distribution pattern of

95 analysis results. The width of

the specification range (USL-LSL) in

comparison to the calculated 6sp range

is a measure for process capability,

expressed as capability indices C

p

.

Figure 3. NWA Quality Analyst:

Control chart based on the average of

7 individual values for each subgroup.

An upper control limit rule violation is

indicated by a “Rule Violation” marker.

A tooltip shows details of the violation.

Implementation of Shewart or Westguard

rules are possible, too

Figure 4. NWA Quality Analyst:

Individual values control chart,

histogram plot, and normal probability

plot can be combined in a single layout.

4

Integration of NWA Quality

Analyst to OpenLAB ECM

clients

Generation of pre-defined control charts can

be triggered directly from the OpenLAB ECM

client. Further automation using OpenLAB

ECM Business Process Manager (BPM) is

possible. Quality Analyst software operates

with various different types of files:

*.DAT files contain the data used to

generate the charts. The *.DAT files could be

stored permanently or just temporarily.

*.NWH files: In case of ECM Intelligent

reporter, the database connection and query

can be stored in this file type. The NWH file

gets generated when saving a new .DAT file.

*.RUN files are script files that could be

used to launch a database connection, call a

.DAT file (and the corresponding .NWH file)

and generate a chart designed by the Run

File Wizard of Quality Analyst

*.NWG files contain an interactive snapshot

of a chart. Storing *.NWH and *.RUN files

in ECM is sufficient to preserve a specific

database query and chart layout. *.DAT files

can always be generated by double-clicking

*.NWH files.

Automated chart generation:

By double-clicking a specific .RUN file

the Quality Analyst software connects to

the database, retrieves the latest data

(dependent on the query definition) and

generates a single or multiple charts as

defined by the run file. This interactive chart

can be stored as an interactive .NWG file or

in any other graphics format (*.png, *.jpg,

*.wmf,*.bmp, *.gif, *.pcx). The chart can be

uploaded to ECM to store the history of all

control charts.

Interactive chart generation:

By double-clicking a specific .NWH file

the Quality Analyst software connects to

the database, retrieves the latest data

(dependent on the query definition) and

shows the data in the Quality Analyst

application window.

The application window allows further

filtering of the data, modification of the

database query and generating all kind of

sophisticated statistics and charts.

Figure 5. Quality Analyst run files stored in OpenLAB ECM

Figure 6. NWA Quality Analyst with query results from OpenLAB ECM Intelligent Reporter

References

1. International Organization for Standardization ISO 9000:2005: Quality management

systems - Fundamentals and vocabulary,

2. International Organization for Standardization ISO/TR 10017:2003: Guidance on

statistical techniques for ISO 9001:2000

3. Joglekar, Anand M.: Statistical methods for six sigma, 2003, Wiley (ISBN

0-471-20342-4)

4. L. Huber: Understanding and Implementing ISO/IEC 17025, 2009, Agilent Technologies

(P/N 5990-4540EN)

5. International Organization for Standardization ISO/IEC 17025:2005: General requirements

for the competence of testing and calibration laboratories

6. Agilent Technologies: Connecting NWA Quality Analyst software to Agilent OpenLAB

ECM Intelligent Reporter (P/N 5991-5439EN)

7. Carson P., Dent N.: Good Clinical, Laboratory and Manufacturing Practices:

Techniques for the QA Professional, 2007, The Royal Society of Chemistry, (ISBN:

978-0-85404-834-2)

8. E. Prichard, V. Barwick: Quality Assurance in Analytical Chemistry, 2007, Wiley (ISBN:

978-0-470-51776-5)

9. Agilent Technologies: Building valuable reports with your Waters Empower Data,

Technical Overview (P/N 5991-1642EN)

10. Agilent Technologies: Supporting Waters Empower 2 Data with OpenLAB Enterprise

Content Manager, Data Sheet (P/N 5990-3240EN)

www.agilent.com/chem/openlab

For research use only. Not for use in diagnostic

procedures. This information is subject to change

without notice.

© Agilent Technologies, Inc., 2015

Published in USA, January 23, 2015

Publication Number 5991-5440EN